Quick synthesizing method of triazinyl covalent bond organic framework material with nano pores and application thereof

An organic framework and nano-hole technology, applied in the field of nano-hole triazine-based covalent bond organic framework materials, can solve the problems of high production cost, low production efficiency, large production energy consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 2.02g (0.0158mol) of terephthalonitrile, then weigh 16.02g (0.118mol) of anhydrous zinc chloride, mix thoroughly and place in a 25ml crucible, then put the crucible with the reaction mixture into the microwave reactor (P70D20SP-DF, China Shenzhen Galanz Co., Ltd.) tray, the output power is 280W. The reaction vessel was reacted under microwave irradiation for 30 minutes, the reaction was stopped, and cooled to room temperature. Soak the resulting reaction mixture in 0.1mol / L hydrochloric acid for 3 hours, filter it with suction, wash it with dilute hydrochloric acid, stir it with dilute hydrochloric acid for 12 hours, filter it with suction again, wash it with deionized water and tetrahydrofuran, and then put the product into a vacuum drying oven Dry at 150 degrees Celsius for 4 hours under the condition of vacuum degree 0.0095Mpa.

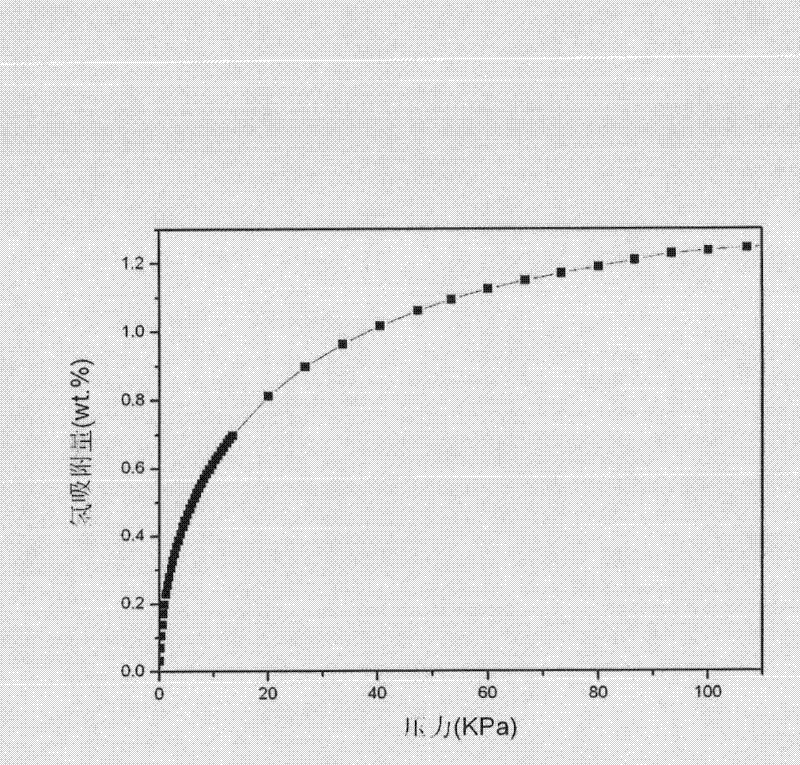

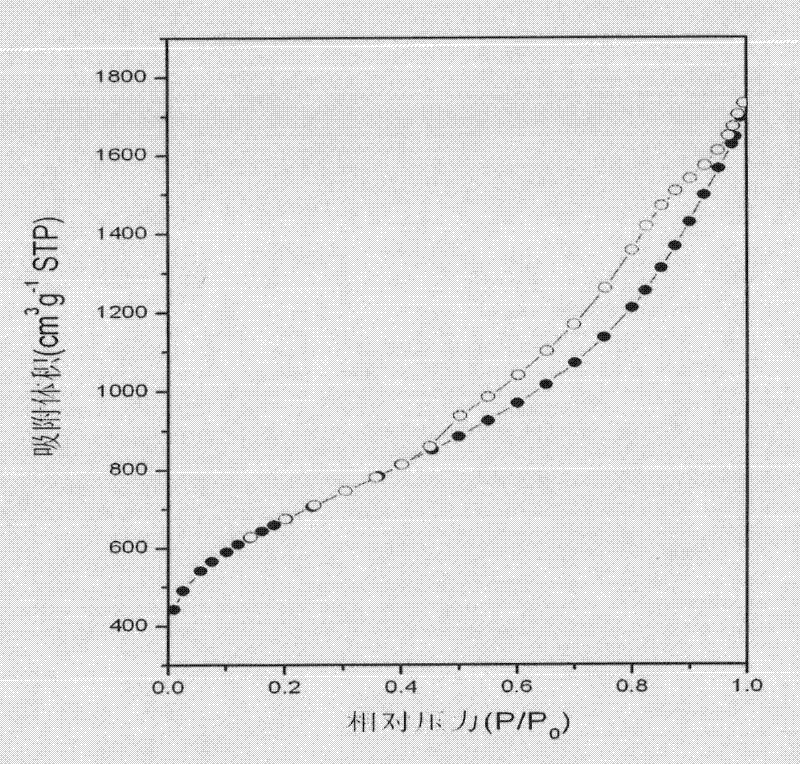

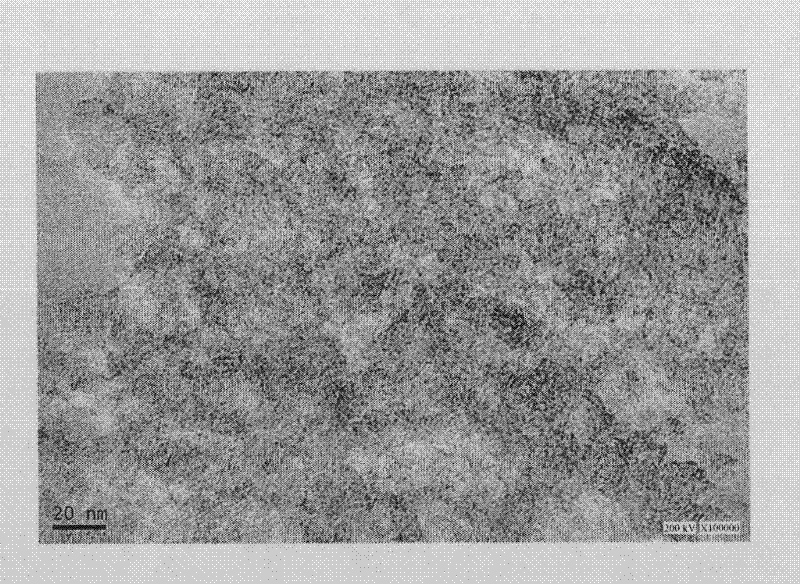

[0035] The pore properties of the product were characterized by a Micromeritics 2020M+C instrument, and the morphology of the produc...

Embodiment 2

[0037] Weigh 2.02g (0.0158mol) of terephthalonitrile, then weigh 16.02g (0.118mol) of anhydrous zinc chloride, mix thoroughly and place in a 25ml crucible, then put the crucible with the reaction mixture into the microwave reactor (P70D20SP-DF, China Shenzhen Galanz Co., Ltd.) tray, the output power is 280W. The reaction vessel was reacted under microwave irradiation for 60 minutes, the reaction was stopped, and cooled to room temperature. Soak the resulting reaction mixture in 0.1mol / L hydrochloric acid for 3 hours, then filter it with suction, wash it with dilute hydrochloric acid, stir it with dilute hydrochloric acid for 12 hours, filter it with suction again, wash it with deionized water and tetrahydrofuran, and then put the product into vacuum drying The box was dried at 150°C for 4 hours under the condition of vacuum degree 0.0095Mpa.

[0038] The pore properties of the product were characterized by a Micromeritics 2020M+C instrument, and the product morphology was cha...

Embodiment 3

[0040] Weigh 2.02g (0.0158mol) of terephthalonitrile, then weigh 16.02g (0.118mol) of anhydrous zinc chloride, mix thoroughly and place in a 25ml crucible, then put the crucible with the reaction mixture into the microwave reactor (P70D20SP-DF, China Shenzhen Galanz Co., Ltd.) tray, the output power is 700W. The reaction vessel was reacted under microwave irradiation for 10 minutes, the reaction was stopped, and cooled to room temperature. Soak the resulting reaction mixture in 0.1mol / L hydrochloric acid for 3 hours, then filter it with suction, wash it with dilute hydrochloric acid, stir it with dilute hydrochloric acid for 12 hours, filter it with suction again, wash it with deionized water and tetrahydrofuran, and then put the product into vacuum drying The box was dried at 150°C for 4 hours under the condition of vacuum degree 0.0095Mpa.

[0041] The pore properties of the product were characterized by a Micromeritics 2020M+C instrument, and the morphology of the product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com