Combined type tuyere small sleeve

A small tuyere sleeve and combined technology, which is applied in the direction of the tuyere, can solve the problems of the small tuyere sleeve, such as poor working conditions, burnout of the small tuyere sleeve, and short service life, so as to improve the cooling effect, reduce the probability of burning out, and reduce the The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

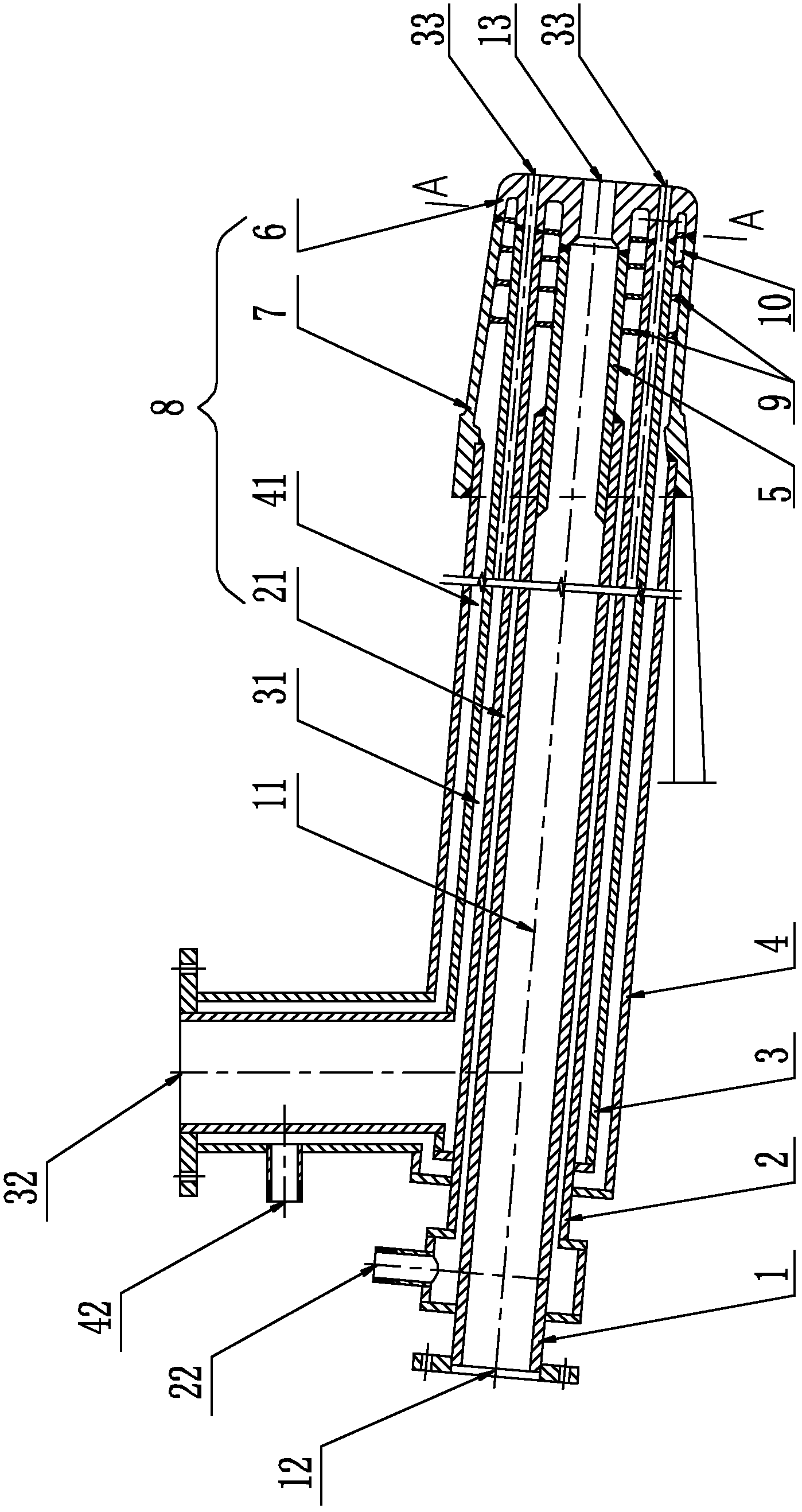

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

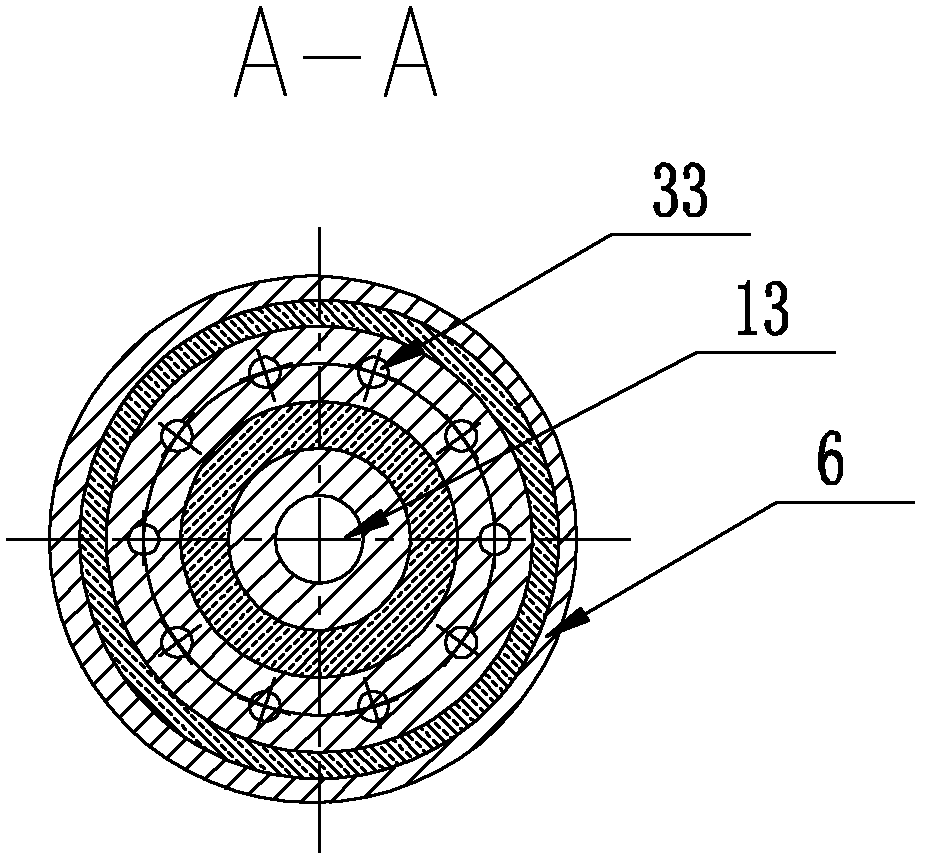

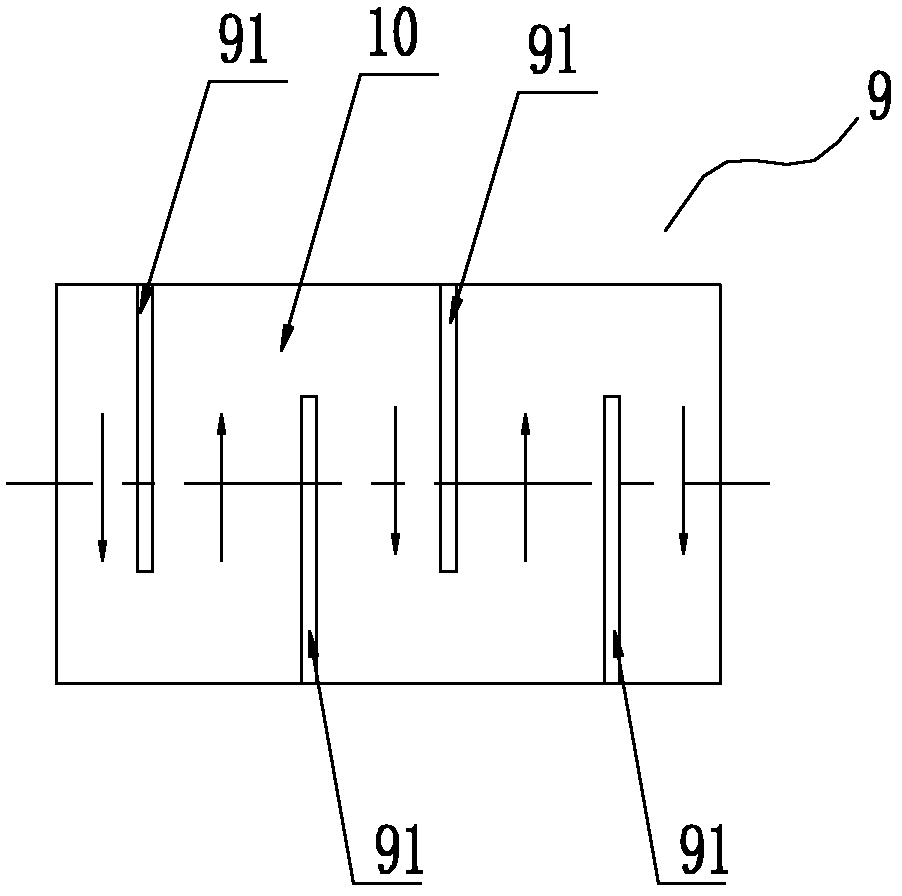

[0033] Please refer to figure 1 , is a structural schematic diagram of the combined tuyere sleeve of the present invention. As shown in the figure, the combined tuyere sleeve proposed by the present invention includes a central sleeve 1, a first sleeve 2, a second sleeve 3, a third sleeve 4, an inner sleeve 5, a front cap 6 and a rear cap 7, One end (rear end) of the central casing 1 is provided with an oxygen-coal medium inlet 12 for inserting an oxygen-coal spray gun (not shown in the figure), and the pulverized coal is transported through the spray gun, and the other end (front end) of the central casing 1 is ) is fixedly connected with an inner sleeve 5, and the central sleeve 1 communicates with the inner cavity of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com