Low-carbon alloy steel smelting method capable of reducing volatile alloy element burning loss, packaging body, long belt of packaging body and feeding method and special feeding device of packaging body

A low-carbon alloy steel and alloying element technology, applied in packaging and other directions, can solve the problems of wasting resources, affecting the rolling effect, and increasing the cost of alloying elements, and achieves the effect of improving the degree of automation, saving production costs, and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

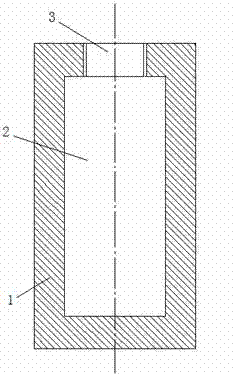

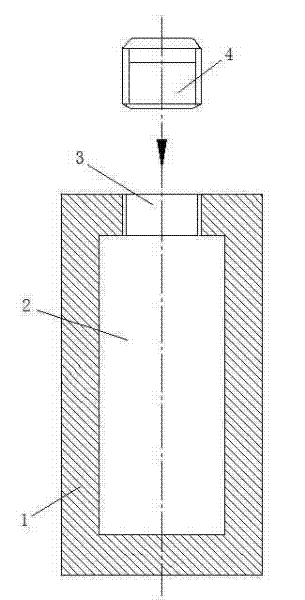

[0029] see figure 1 and figure 2 The low-carbon alloy steel smelting method of the present invention to reduce the burning loss of volatile alloy elements is to add the packaging body containing volatile metals into molten steel through a special feeding device at the later stage of low-carbon steel smelting, so as to realize the reduction of volatile alloy elements. Alloying, the outer packaging layer of the packaging body is made of pure iron material to form a protective layer of volatile metals. In the later stage of smelting low-carbon alloy steel, such as 1-10 minutes before tapping, observe the molten steel through the observation hole. After the molten steel in the furnace is evenly mixed and the bubbles have completely floated up, wrap the volatile alloy element material with a pure iron outer packaging layer. Wrapping forms a packaging body, which can prevent alloy elements from being exposed, and finally adds the packaging body containing volatile alloy element ma...

Embodiment 2

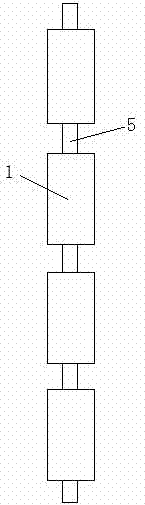

[0037] The packaging body of the volatile alloy element material in this embodiment is basically the same as that of Embodiment 1. The special feature is that each packaging body is connected to form a long strip. The specific technical scheme is as follows:

[0038] see image 3 In order to continuously add the volatile alloy element material into the molten steel, the monomers of the packaging body containing the volatile alloy element material in Embodiment 1 are connected to form a length of the package body of the volatile alloy element material. The belt is formed by sequentially connecting the pure iron outer coating layer 1 of the packaging body of a plurality of volatile alloy element materials through connecting parts 5 to form a long belt shape. The connecting parts of the long belt have a certain strength and will not be broken. A series of packages are sequentially connected and stored or arranged on the raw material supply line equipment.

[0039] Using the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com