Novel water cooling system joint

A water-cooling system, a new type of technology, applied in the direction of pipes/pipe joints/fittings, sealing surface connections, passing components, etc., can solve the problem of large installation errors of synthetic material pipes, high cost of steel pipe collars, and incompatibility of connected round holes, etc. problems, to achieve the effect of saving material costs, simple structure, and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

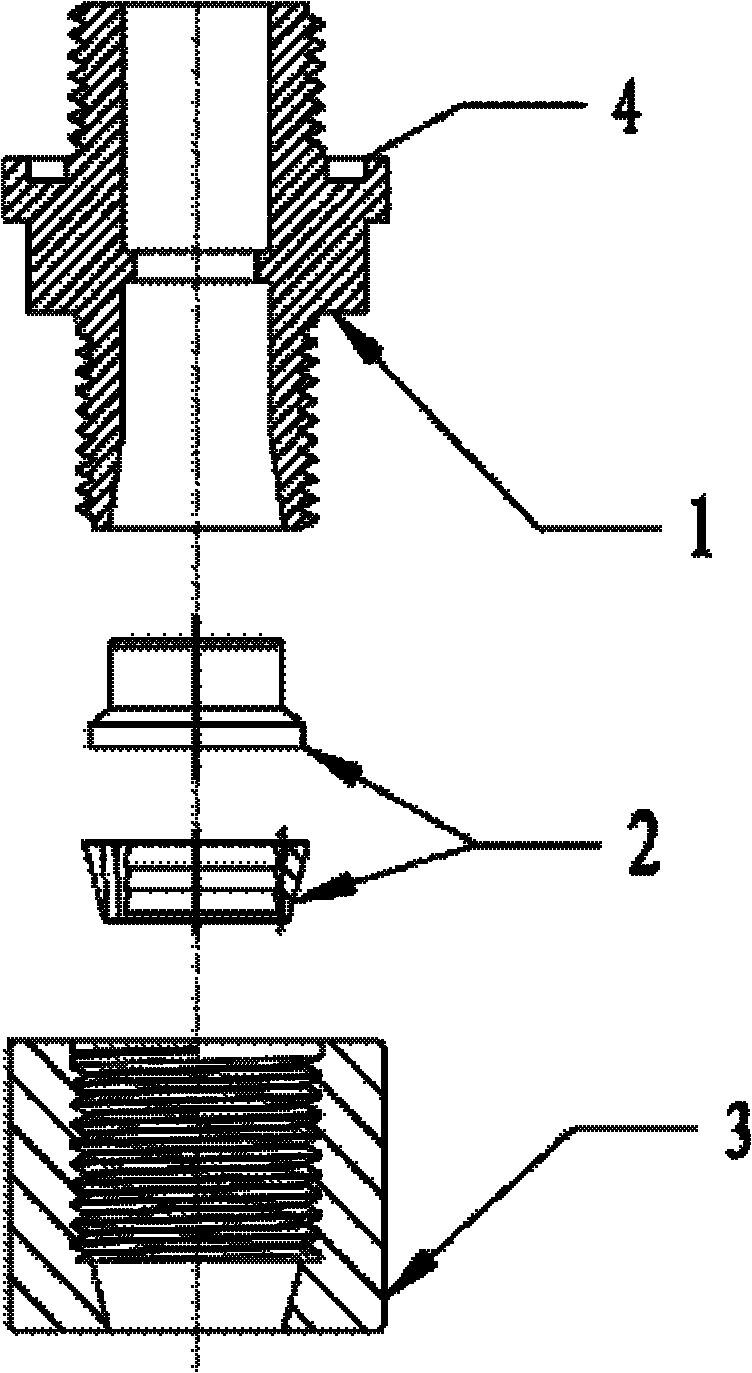

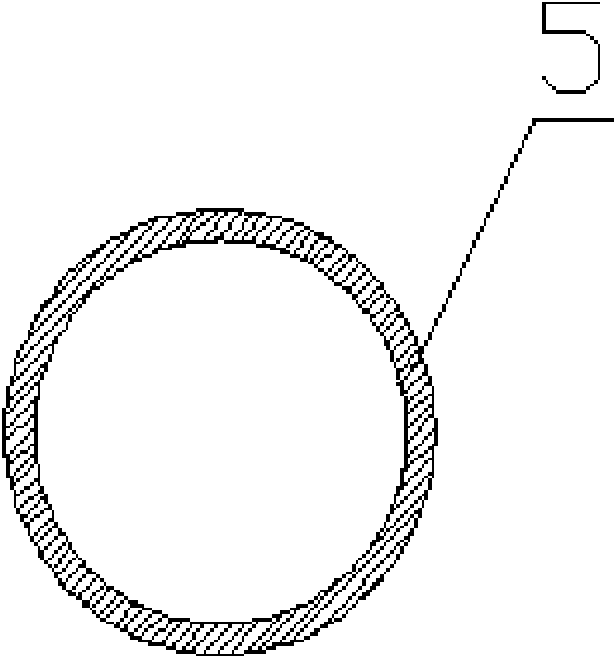

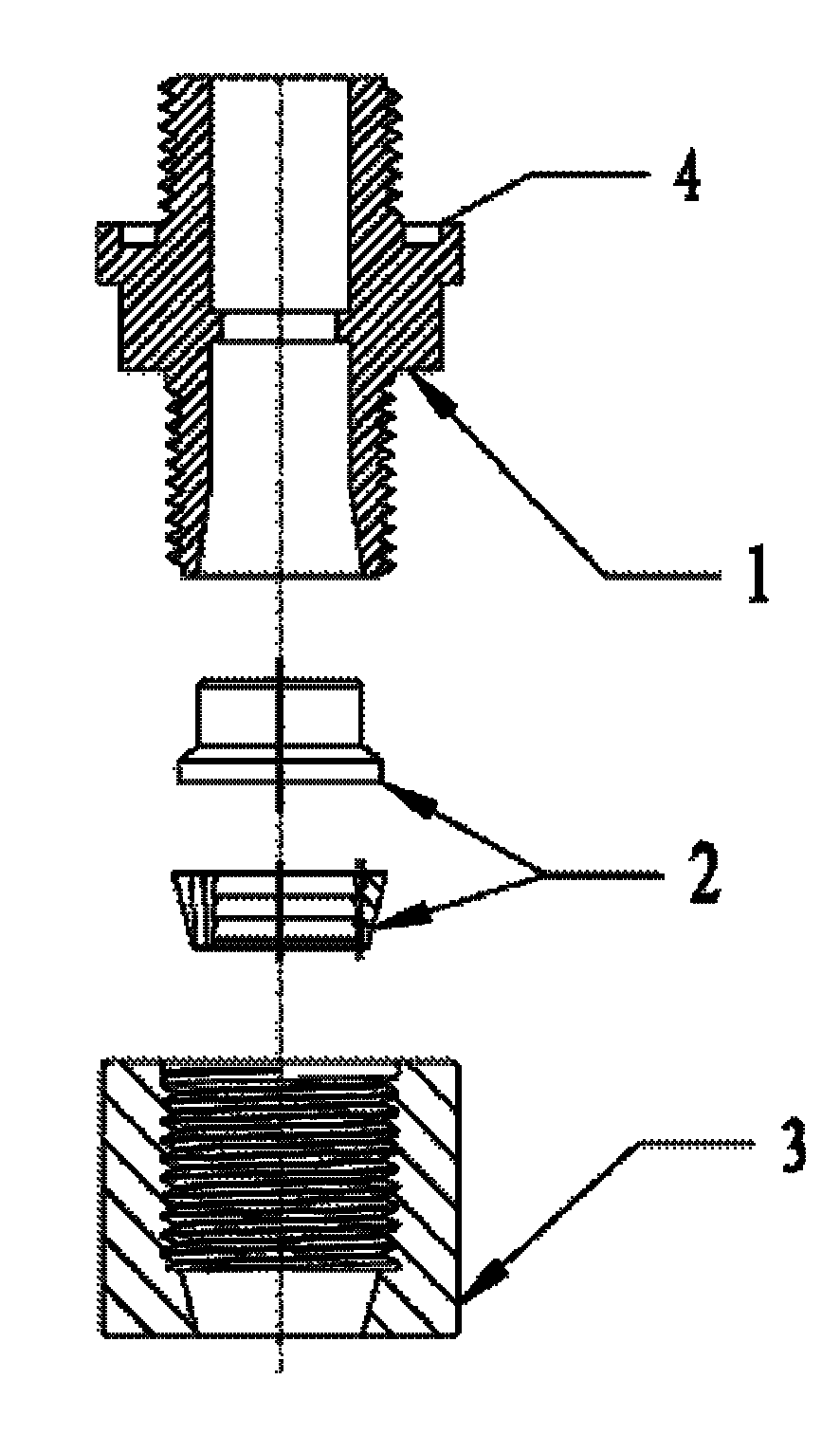

[0025] Such as Figure 1-2 As shown, a new type of water-cooling system joint invented in this example includes a double-ended screw 1, a lock nut 3, a bushing 2, a groove 4 and an O-ring 5, and the inside of the double-ended screw 1 is a hollow screw. A bushing 2 is provided between the stud screw 1 and the lock nut 3. There are two bushings 2. The two bushings 2 are conical. The center of the bushing 2 coincides with the axis of the stud screw 1. One The shape of the conical surface of the bushing 2 is the same as the inner shape of one end of the stud screw 1 , and the shape of the conical surface of the other bushing 2 is the same as the inner shape of one end of the lock nut 3 .

[0026] The two conical bushes 2 are arranged in a way that the cone bottoms are facing each other. The top of one bush 2 protrudes into one end of the stud screw 1 for sealing butt joint, and the bottom of one bush 2 is docked with the bottom of the other bush 2. , the bottom of the other bushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com