Automatic assembling machine for bead-spitting fireworks

A technology for assembling machines and fireworks, which is applied in the fields of pyrotechnics, weapon types, offensive equipment, etc., can solve problems such as lack of human-machine isolation, low safety factor, and high potential safety hazards, and achieve convenient and quick equipment maintenance, broad prospects, and guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

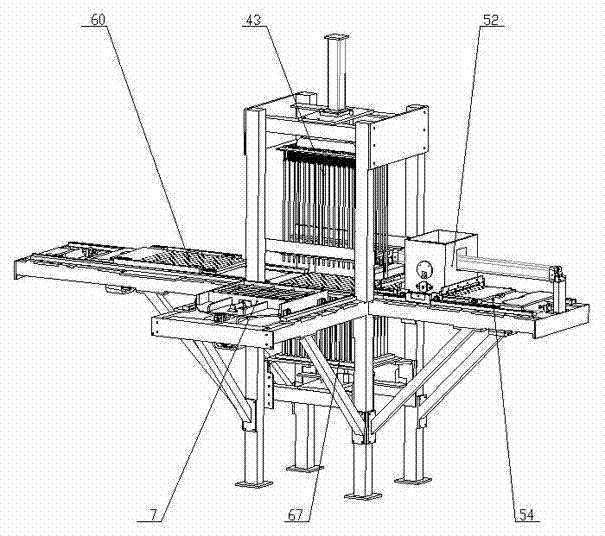

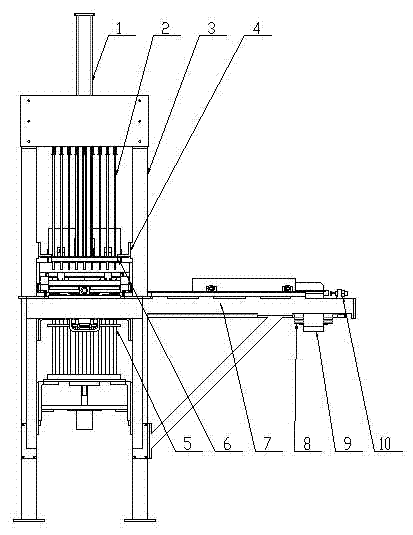

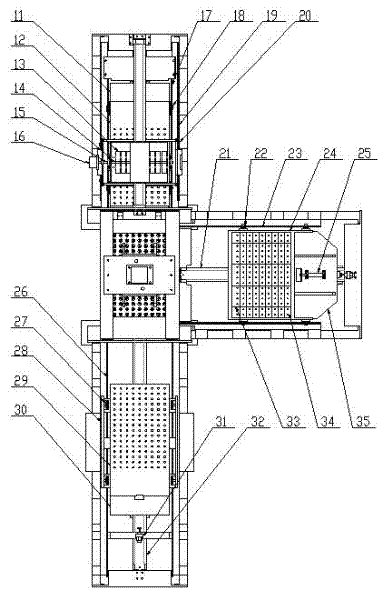

[0017] combine figure 1 , figure 2 , image 3 and Figure 4 , the automatic assembling machine for bead-spitting fireworks of the present invention is composed of a propellant transmission and drive module 7, a bright bead transmission and drive module 60, a delay medicine box transmission and drive module 52, a delay medicine transmission and drive module 54, and an assembly pressure bar drive module 43 and the cylinder box driving and positioning module 67, wherein the delay medicine transmission and driving module 54, the bright bead transmission and driving module 60, and the propellant transmission and driving module 7 are respectively located on the east side and west side of the workbench 44 in the fuselage 3. Side, south three directions, and be in the same horizontal position with workbench 44. Fuselage 3 is a conventional component, and is made up of four columns, and workbench 44 is connected together with four columns. On the east side of the workbench 44, a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com