Constant-power control circuit of electric vibrator during cement production

A technology of constant power control and control circuit, which is applied in the direction of control/regulation system, adjustment of electric variables, instruments, etc. It can solve the problems of material change, no consideration of the influence of the AC power supply of the electric vibrator, and constant power operation of the electric vibrator. To achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

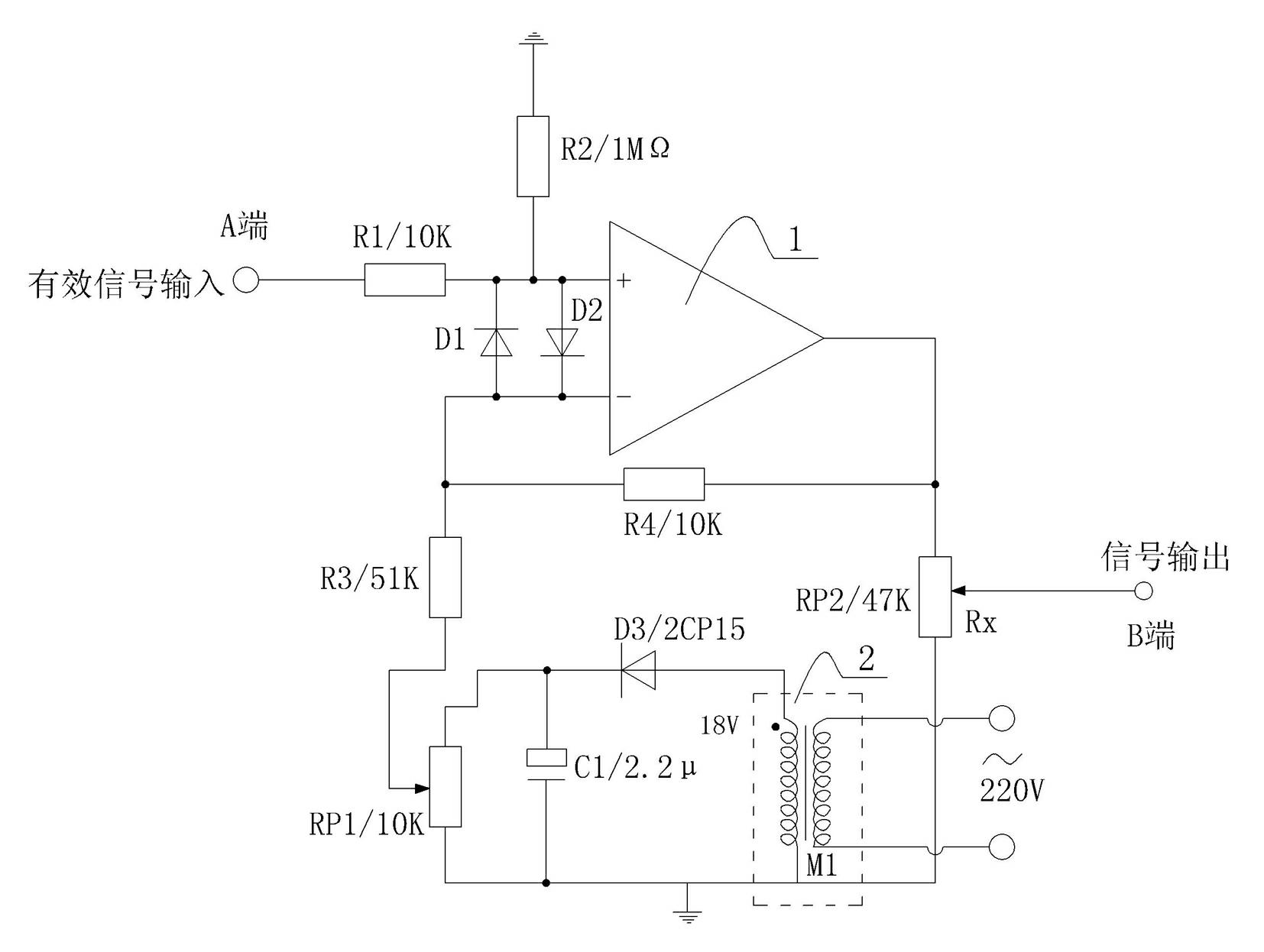

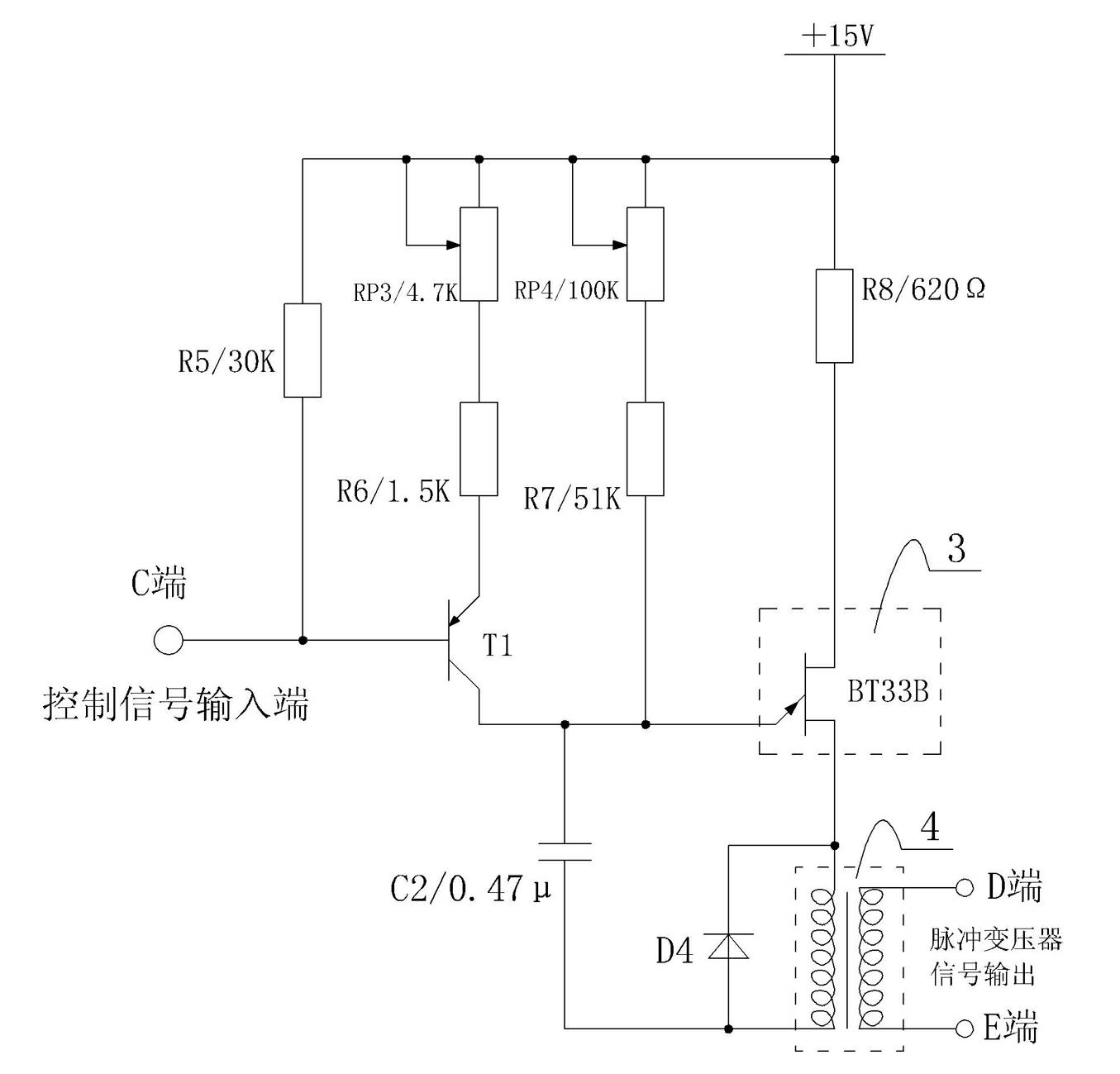

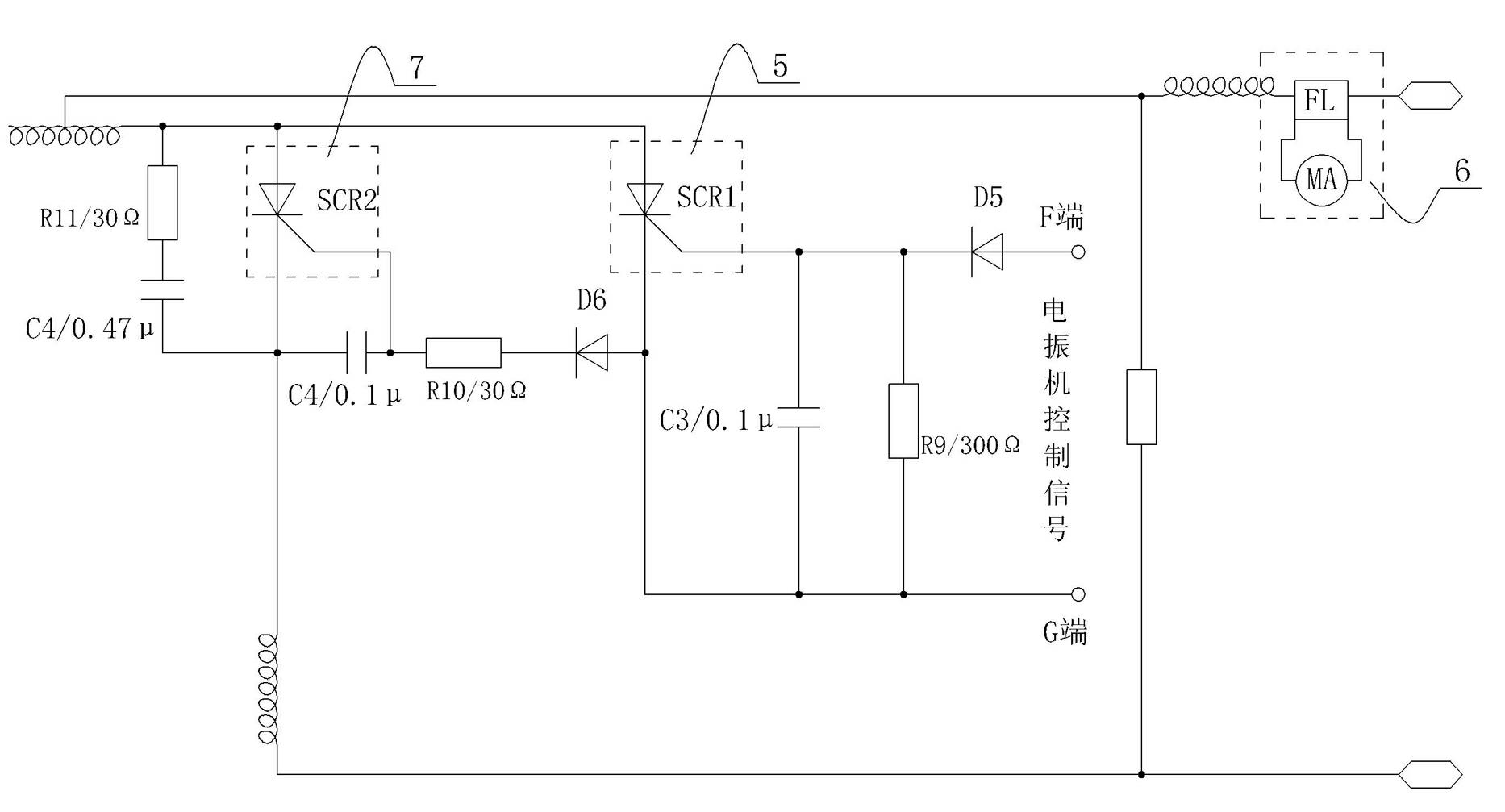

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] Such as Figure 4 As shown, a schematic diagram of the structure of the batching device in the cement plant is given, which includes a microcomputer scale 10, an electric vibrator 11, a gate valve 12, and a storage bin 13. The storage bin 13 is used to hold different types of cement raw materials. Material, gate valve 12 is arranged on the outlet of storage bin 13 below. The electric vibrator 11 is arranged below the outlet of the storage bin 13, and the cement raw meal is discharged through the vibration of the electric vibrator 11. The raw meal falling from the electric vibrator 11 is weighed on the microcomputer scale 10 and further transmission. Now some manufacturers microcomputer scales 10 also adopt electronic scales. The microcomputer claims 10 also outputs a feedback signal for controlling the electric vibration machine 11, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com