Device for cleaning and treating substrate

A treatment device and water washing treatment technology, applied in the direction of spraying device, spraying device, cleaning method and utensils, etc., which can solve the problems of large occupied area of replacement washing chamber 40, longer processing time, larger occupied area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention will be described below with reference to the drawings.

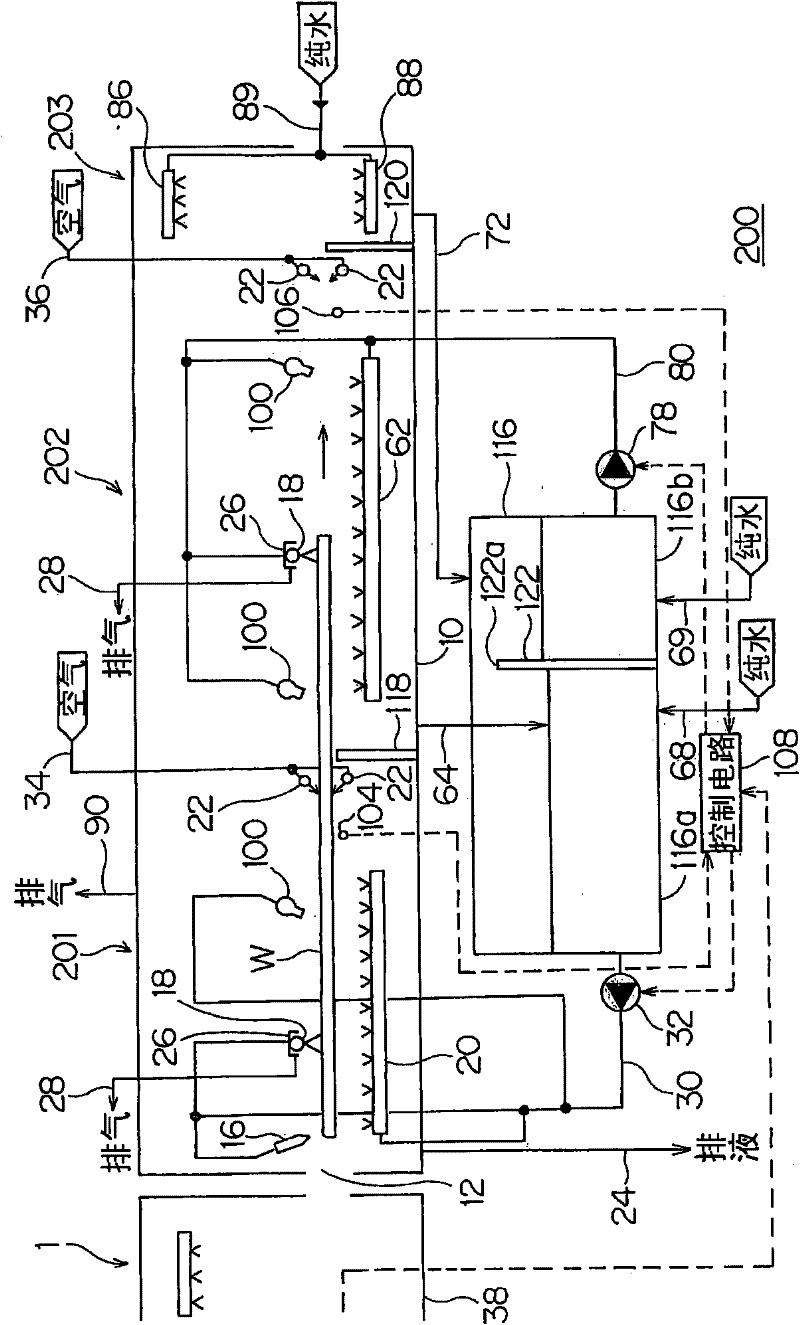

[0056] figure 1 An example of an embodiment of the present invention is shown, and it is a diagram schematically showing a substrate cleaning processing apparatus 200 . Additionally, with Figure 11 The structural elements and components shown in the same or corresponding structural elements and components, in figure 1 The same reference numerals are also used in .

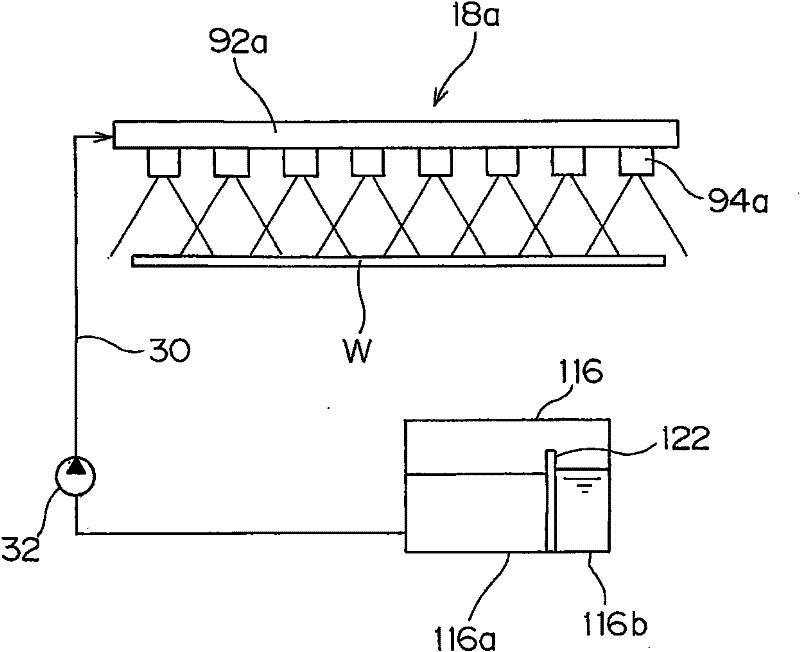

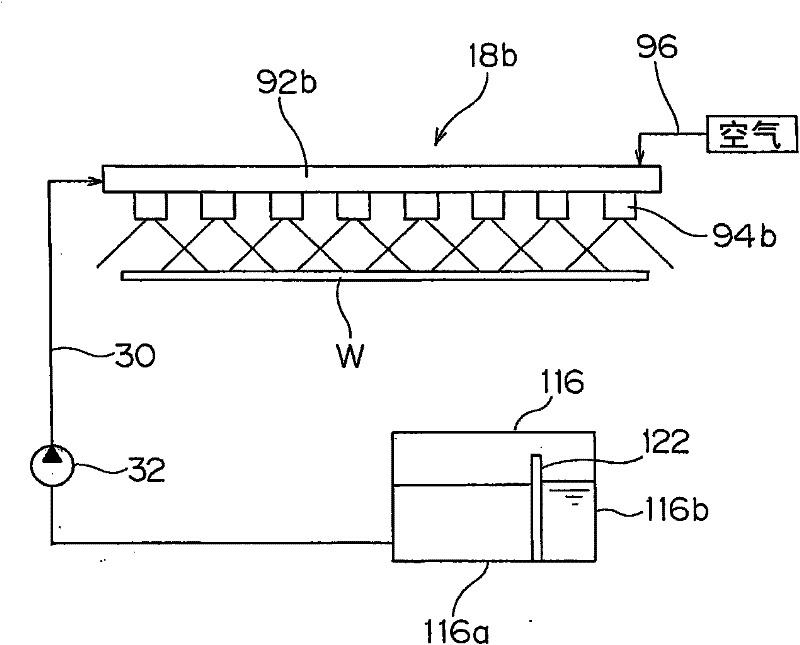

[0057] This substrate cleaning treatment apparatus 200 includes a water washing treatment chamber 10, a circulating water tank 116, and the like disposed on the rear stage side of the chemical solution processing unit 1 (only a part is shown in the figure), and a drying treatment unit is provided on the rear stage side of the water washing treatment chamber 10. (not shown).

[0058] The washing treatment chamber 10 is sequentially divided into a replacement washing area 201 , a washing area 202 , and a direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com