Wheat seeding and fertilizing integration method

A wheat and fertilizer applicator technology, applied in the directions of planter parts, fertilizers and planting equipment, etc., can solve the problems of increasing labor input costs, inability to mechanize wheat operations, and low fertilizer utilization rate, etc. efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

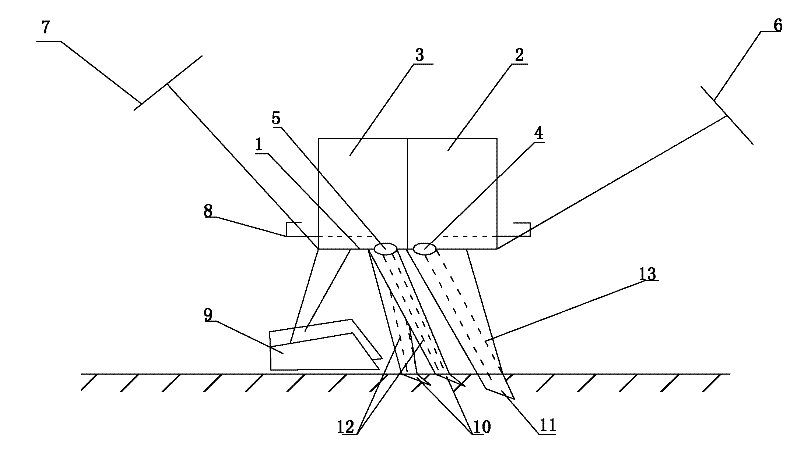

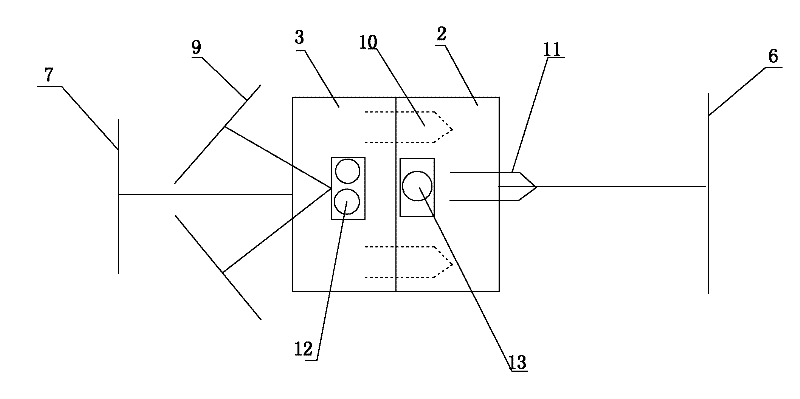

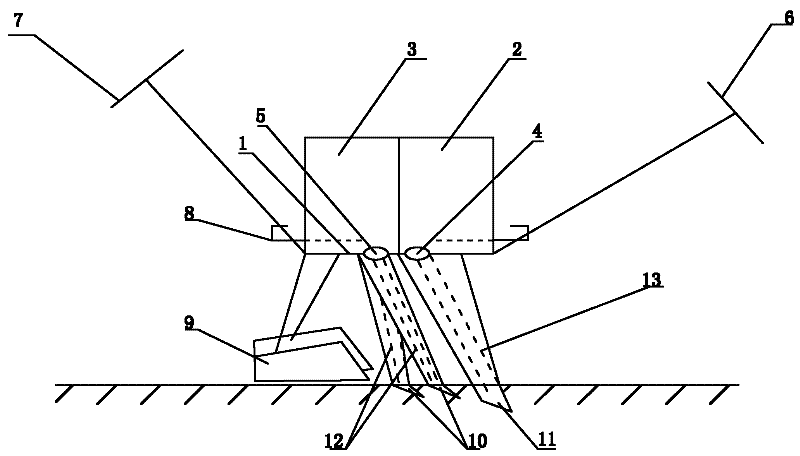

[0031] The integrated method of wheat sowing and fertilization, using such as figure 1 , figure 2 The seeding and fertilizing machine of the shown structure is carried out in the following steps:

[0032] (1) Before sowing and fertilizing operations, carry out the test of seeding rate and fertilization rate:

[0033] Seeding amount test: the opener does not enter the soil, pull the sowing and fertilizing device to walk, count the number of discharged seeds, pull the insert at the outlet of the seed box to adjust the size of the seed outlet, so that the seeding amount is controlled in double rows The seeding rate is 115 grains / m, until the seeding rate matches the theoretical seeding rate;

[0034] Fertilization amount test: the ditch opener does not enter the soil, pull the planting and fertilizing device to walk, pull the insert at the outlet of the fertilizer box to adjust the size of the fertilizer outlet, so that the amount of fertilizer discharge is controlled at a sin...

Embodiment 2

[0043] As described in embodiment 1, the difference is that the described seeding and fertilizing machine has the following aspects with embodiment 1:

[0044] The seed discharge port 5 and the fertilizer discharge port 4 are circular with a diameter of 3.2 cm.

[0045] The seed delivery pipe 12 is a soft plastic pipe with an inner diameter of 1.6cm, and the fertilizer delivery pipe 13 is a soft plastic pipe with an inner diameter of 1.8cm.

[0046] The distance between the two sowing openers 10 is 18cm.

[0047] Two earth-covering boards 9 front end spacings are 28cm, and material is plank.

[0048] The lower end of the sowing ditch opener 10 is 4.5cm higher than the lower end of the fertilizer ditch opener 11, and the lower end of the cover plate 9 is 3cm higher than the sowing ditch opener 10.

[0049] The front end of sowing ditch opener 10 is apart from the front end 16cm of fertilizer ditch opener 11.

[0050] Balance bar 7 and draw bar 6 materials are wooden bars.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com