Steel grating plate press welder

A technology of steel grating and pressure welding machine, which is applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of slow feeding speed, complex structure, poor precision, etc. The effect of high precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

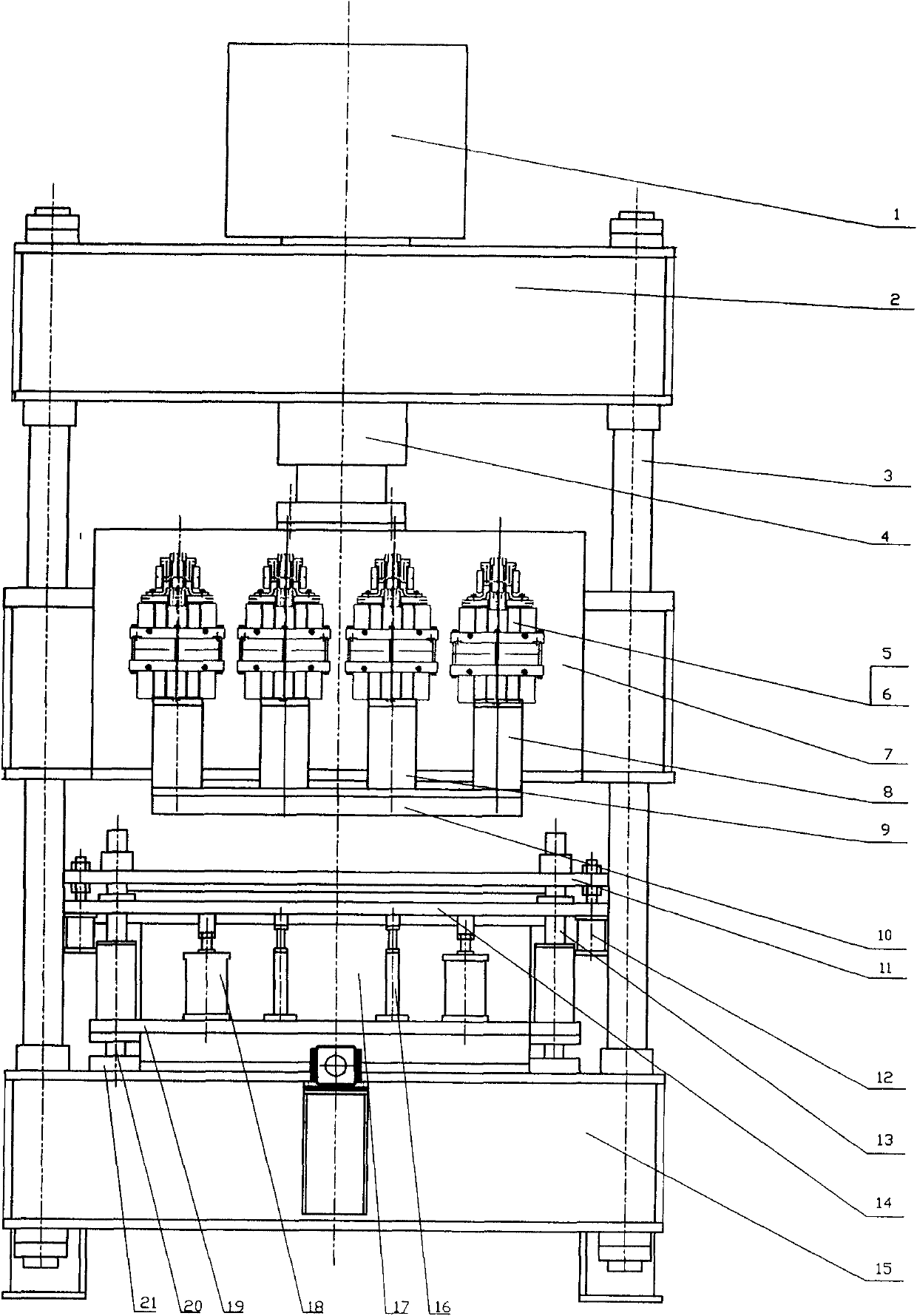

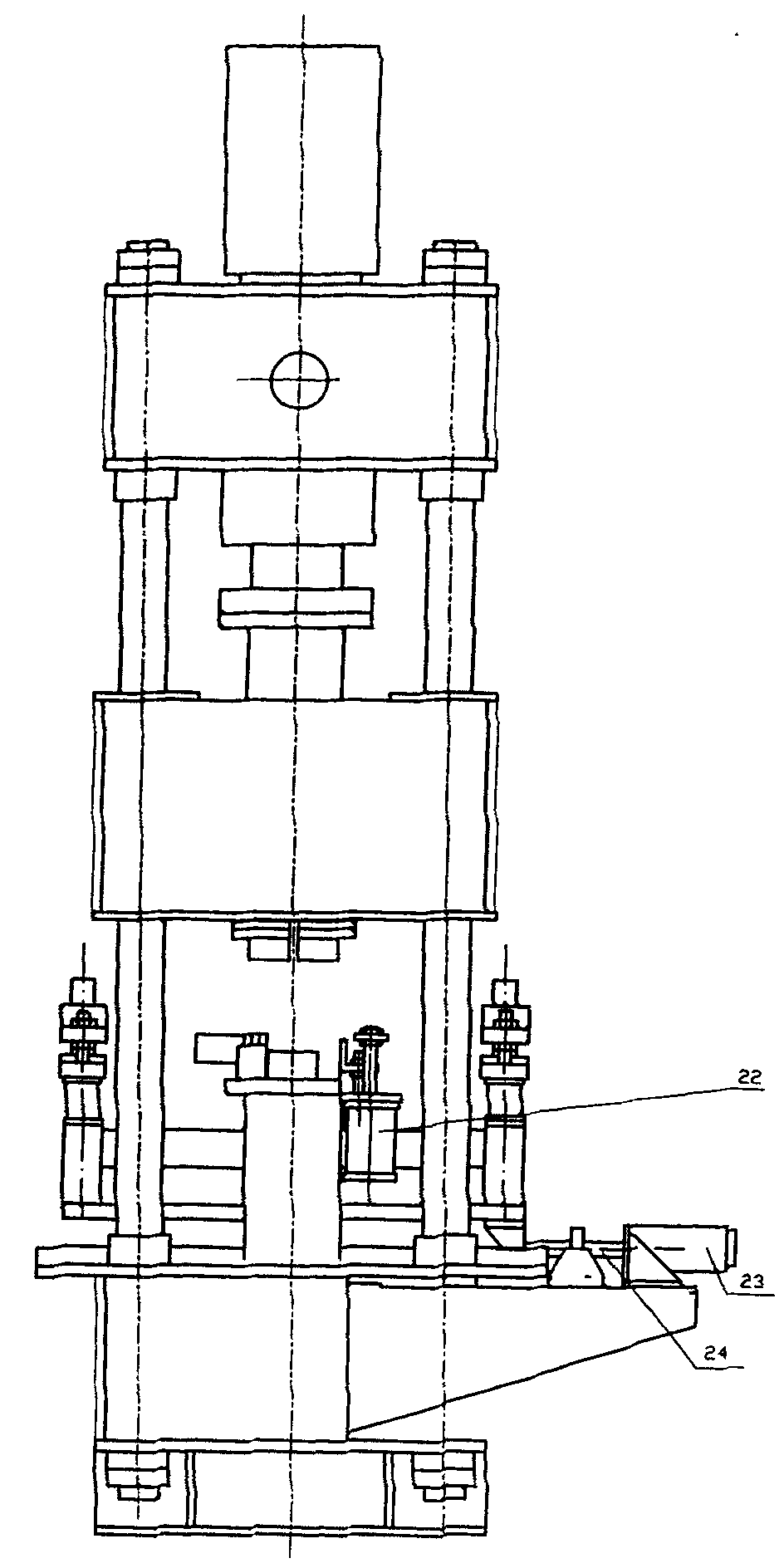

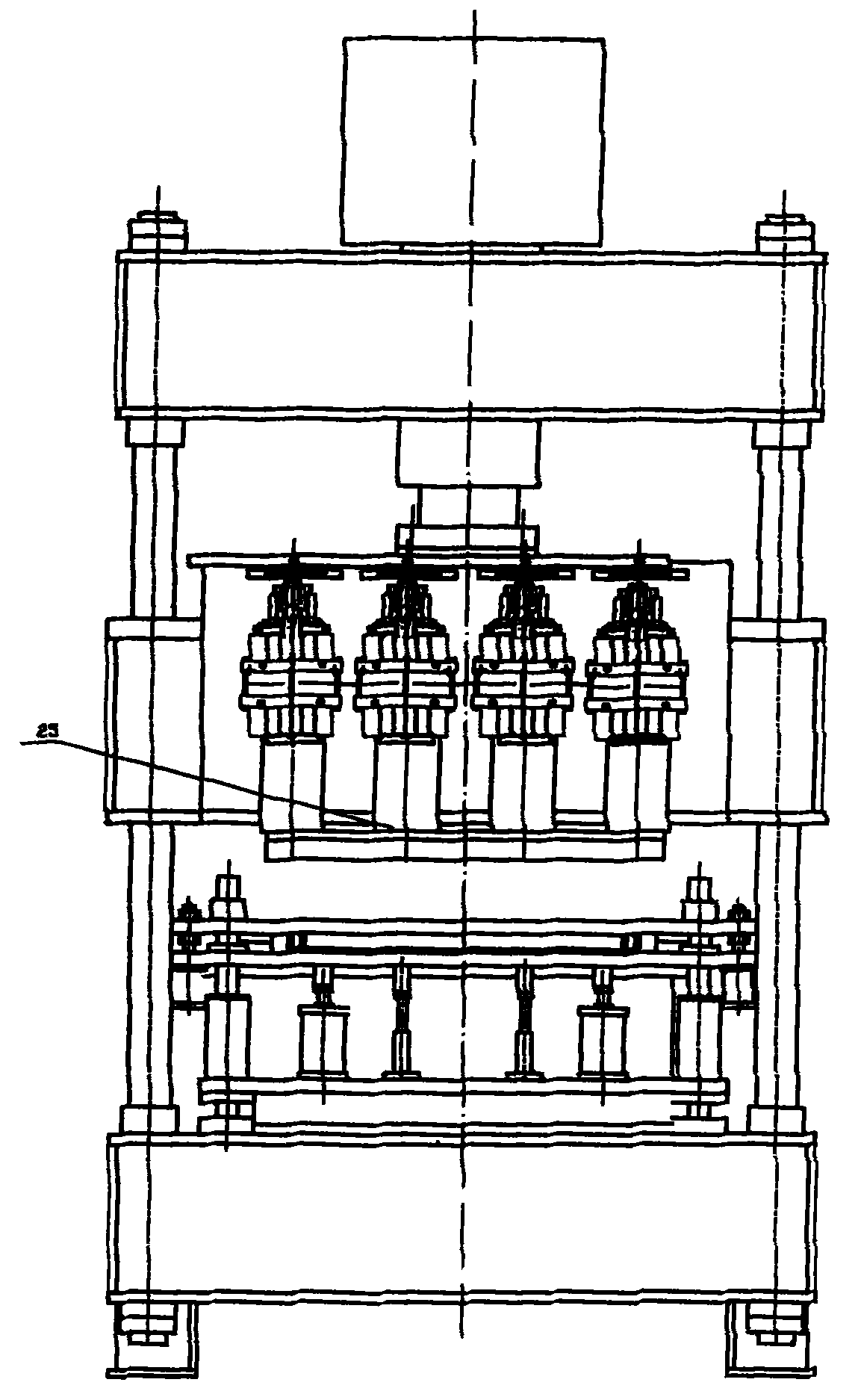

[0012] The front side of the lower beam 15 is connected to the servo motor 23, the output end of the servo motor 23 is connected to the ball screw 24, the upper end of the ball screw 24 is connected to the feeding frame 19, and the lower sides of the two ends of the feeding frame 19 are fixedly connected to the linear guide rail 20, and the linear guide rail 20 The lower end is connected to the linear guide rail base plate 21, the lower end of the linear guide rail base plate 21 is connected to the lower beam 15, the middle part of the upper end of the feeding frame 19 is connected to the lower clamping cylinder 18, and the two ends are connected to the guide post 13, the guide post 13 The upper end is connected to the lower clamping plate 14; at least three pairs of transformers 5 are connected to both sides of the middle of the slider 7, and each transformer 5 is connected to at least six diode rectifier assemblies 6, and the lower end of the transformer 5 is respectively conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com