Oyster box-type rock and roll rotational molding machine

A rotomolding machine and clam box technology, applied in the direction of coating, etc., can solve the problems of high toxicity of liquid FRP, inconsistent product wall thickness, uneven heating of the mold, etc., to achieve consistent wall thickness, long service life, and high heat utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

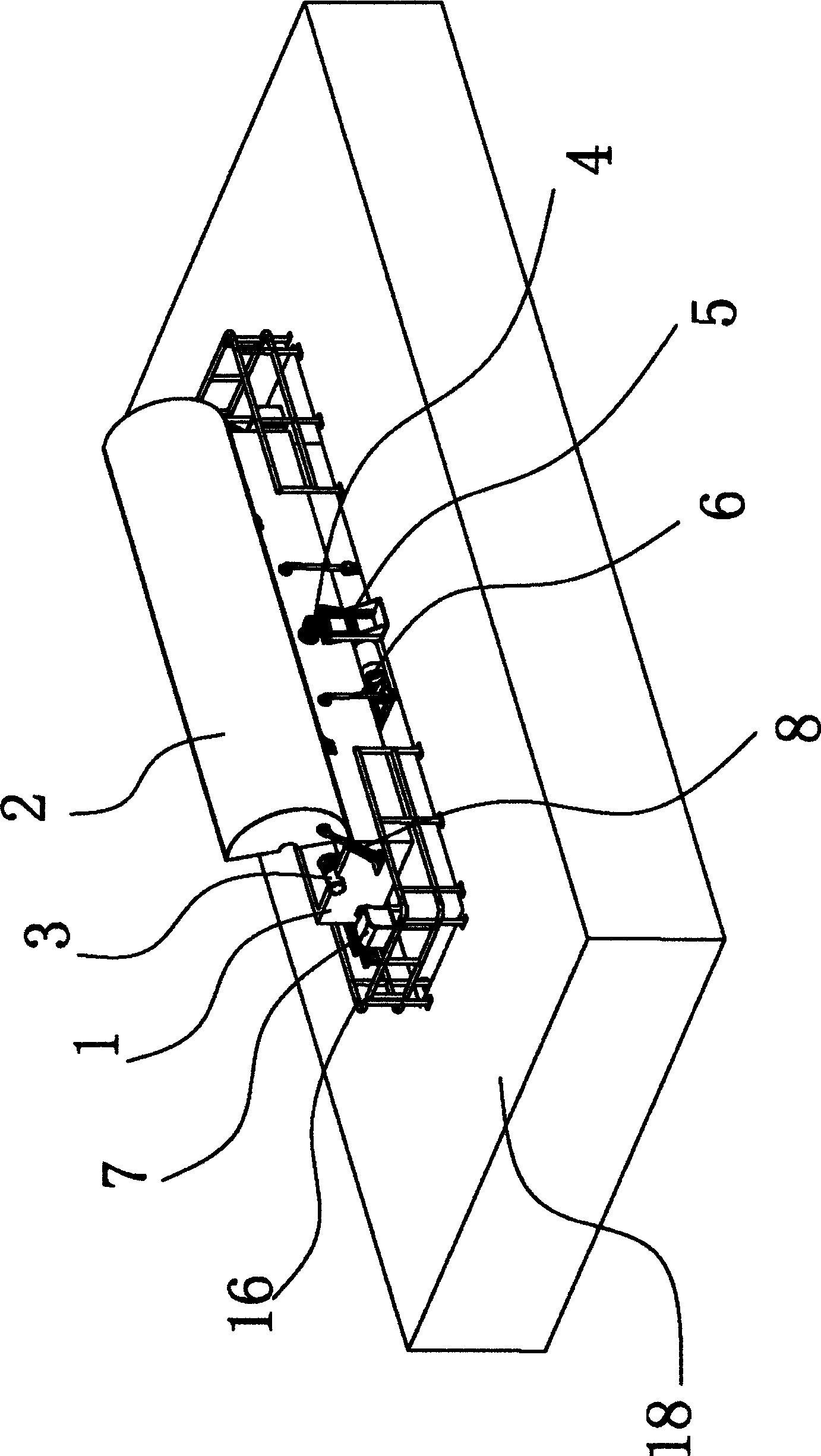

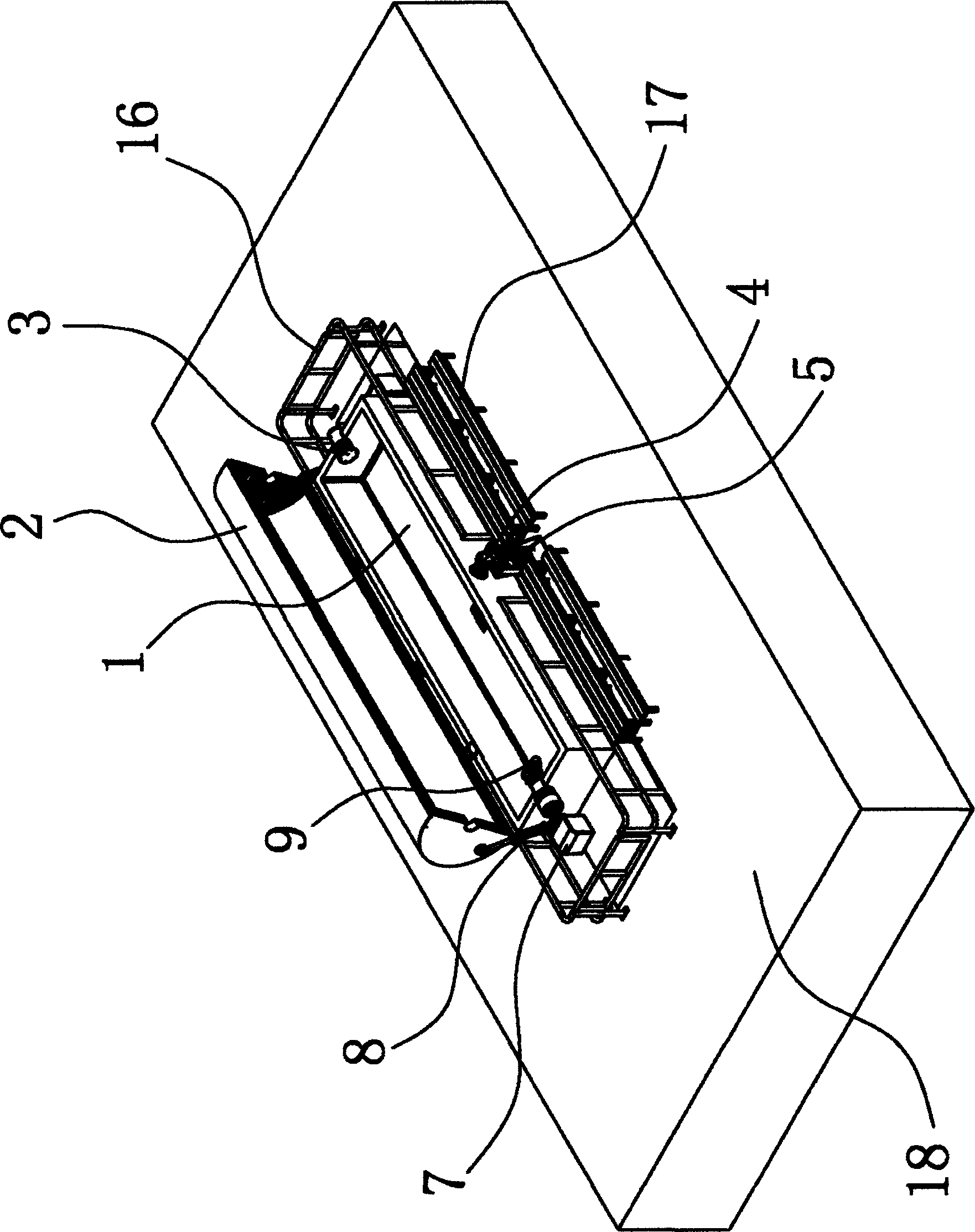

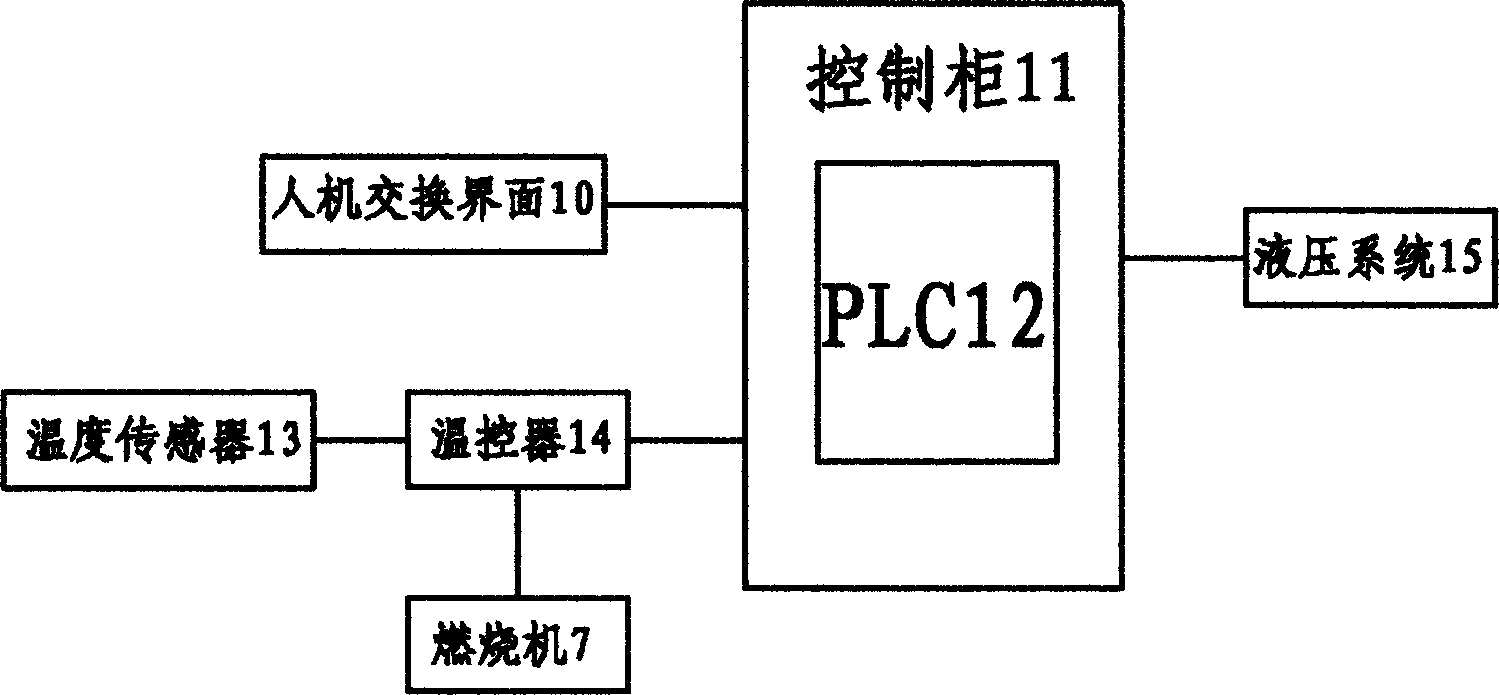

[0021] Such as figure 1 , 2 As shown in and 3, the clam box type rocking rotomolding machine includes a clam box 1, a clam cover 2 hingedly connected with the clam box 1, a hydraulic system 15 with a hydraulic motor, a control cabinet 11 based on a PLC 12, a temperature control device and The man-machine exchange interface 10, the joint surface of the clam box 1 and the clam cover 2 is fixed with a support seat 3 for supporting the mold and the hydraulic motor, and the hydraulic motor and the support seat 3 are connected at the outer end of the clam box 1 and can drive the support seat 3 Rotate, the middle of both sides of the clam box 1 is respectively provided with a swing short shaft 4, and a bearing seat 5 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com