Environment-friendly road surface ice and snow melt coating material, preparation method thereof and using method thereof

A coating material and an environment-friendly technology, which is applied in the field of environment-friendly pavement ice and snow melting coating materials and its preparation, can solve the problems of incomplete removal of pavement ice, large environmental impact, and damage to pavement structure, so as to prevent the pavement from loosening particle size, simple construction process, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

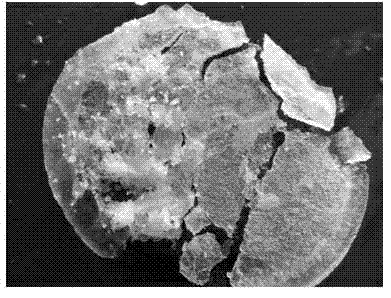

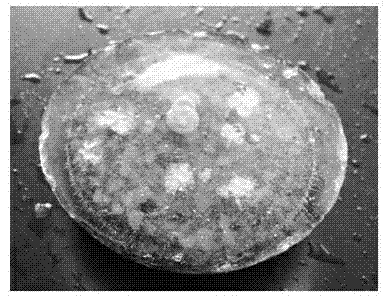

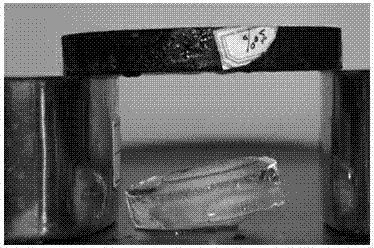

Image

Examples

Embodiment 1

[0040] Step 1: Add 10 parts by weight of magnesium chloride to 50 parts by weight of water, after completely dissolving, use 0.5mol / L sodium hydroxide solution to adjust the pH to 8, then add 10 parts by weight of diatomaceous earth, stir evenly and bake Dry grinding and passing through a 50-mesh sieve to obtain carrier powder containing snow-melting substances;

[0041] Step 2: Add 15 parts by weight of carrier powder containing snow-melting substances to 10 parts by weight of cationic emulsified asphalt, then add 10 parts by weight of water-based epoxy resin, 10 parts by weight of water, and 2 parts of 703 curing agent to obtain Melting ice and snow coating materials.

[0042] The usage method of the environment-friendly type pavement ice and snow melting coating material that the present embodiment obtains comprises the following steps successively:

[0043] Step 1: Clean the road surface with a broom or cleaning machine. If there is water on the road surface, use an air c...

Embodiment 2

[0051] Step 1: Add 20 parts by weight of calcium chloride to 60 parts by weight of water, after completely dissolving, use 0.5mol / L sodium hydroxide solution to adjust the pH to 8, then add 20 parts by weight of silica gel, stir evenly and bake Dry grinding and passing through a 60-mesh sieve to obtain carrier powder containing snow-melting substances;

[0052] Step 2: Add 25 parts by weight of carrier powder containing snow-melting substances to 10 parts by weight of cationic emulsified asphalt, then add 10 parts by weight of water-based epoxy resin, 20 parts by weight of water, and 6 parts of 703 curing agent to obtain Melting ice and snow coating materials.

[0053] The usage method of the environment-friendly type pavement ice and snow melting coating material that the present embodiment obtains comprises the following steps successively:

[0054] Step 1: Clean the road surface with a broom or cleaning machine. If there is water on the road surface, use an air compressor ...

Embodiment 3

[0062] Step 1: Add 30 parts by weight of sodium chloride into 70 parts by weight of water, after completely dissolving, use 1mol / L sodium hydroxide solution to adjust the pH to 9, then add 30 parts by weight of volcanic rock bentonite, stir evenly and bake Dry grinding and passing through a 70-mesh sieve to obtain carrier powder containing snow-melting substances;

[0063] Step 2: Add 30 parts by weight of carrier powder containing snow-melting substances to 20 parts by weight of cationic emulsified asphalt, then add 20 parts by weight of water-based epoxy resin, 30 parts by weight of water, and 10 parts by weight of 120 curing agent to obtain Melting ice and snow coating materials.

[0064] The usage method of the environment-friendly type pavement ice and snow melting coating material that the present embodiment obtains comprises the following steps successively:

[0065] Step 1: Clean the road surface with a broom or cleaning machine. If there is water on the road surface,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com