Preparation method and application method of coating material capable of actively adjusting temperature of road

A technology of coating materials and pavement temperature, which can be used in coatings, asphalt coatings, epoxy resin coatings, etc. Reduce the durability of pavement and other problems, and achieve the effect of preventing the pavement from loosening and dropping particles, reducing the cost of coating and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

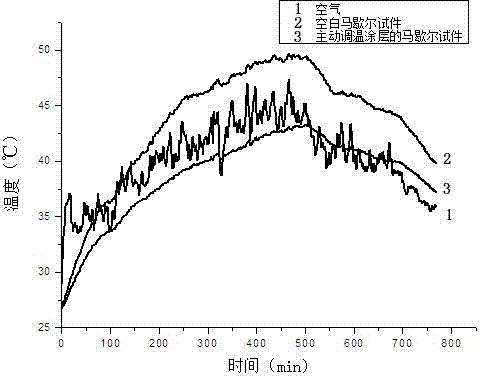

Image

Examples

Embodiment 1

[0035] Step 1: Calcining 10 parts by weight of the porous framework material at 450°C for 2 hours, cooling to room temperature, adding 50 parts by weight of 70% sulfuric acid solution, placing it in a constant temperature water bath at 70°C for 3 hours, and then adding Dilute with deionized water and filter until the filtrate is neutral;

[0036] Step 2: Transfer the material obtained in Step 1 into a dry container, dry it in a constant temperature drying oven at 110°C for 24 hours, and grind it to 50 mesh for later use;

[0037] Step 3: Weigh 10 parts by weight of the energy storage phase change material and add it to 50 parts by weight of absolute ethanol and stir to form a solution; then weigh 10 parts by weight of the material obtained in Step 2 and add it, and place it in a constant temperature water bath at 70°C Stir for 2 hours, dry and grind to obtain a modified energy storage phase change material;

[0038] Step 4: Weigh 20 parts by weight of the modified energy stor...

Embodiment 2

[0044]Step 1: Calcining 10 parts by weight of the porous framework material at 470°C for 2.5 hours, cooling to room temperature, adding 60 parts by weight of 70% sulfuric acid solution, placing it in a constant temperature water bath at 70°C for 3 hours, and then adding Dilute with deionized water and filter until the filtrate is neutral;

[0045] Step 2: Transfer the material obtained in Step 1 into a dry container, dry it in a constant temperature drying oven at 110°C for 24 hours, and grind it to 60 mesh for later use;

[0046] Step 3: Weigh 20 parts by weight of the energy storage phase change material and add it to 50 parts by weight of absolute ethanol and stir to form a solution; then weigh 20 parts by weight of the material obtained in Step 2 and add it, and place it in a constant temperature water bath at 70°C Stir for 2 hours, dry and grind to obtain a modified energy storage phase change material;

[0047] Step 4: Weigh 25 parts by weight of the modified energy sto...

Embodiment 3

[0054] Step 1: Calcining 20 parts by weight of the porous framework material at 490°C for 3 hours, cooling to room temperature, adding 70 parts by weight of 70% sulfuric acid solution, placing it in a constant temperature water bath at 70°C for 3.5 hours, and then adding Dilute with deionized water and filter until the filtrate is neutral;

[0055] Step 2: Transfer the material obtained in Step 1 into a dry container, dry it in a constant temperature drying oven at 110°C for 24 hours, and grind it to 70 mesh for later use;

[0056] Step 3: Weigh 30 parts by weight of the energy storage phase change material and add it to 60 parts by weight of absolute ethanol and stir to form a solution; then weigh 30 parts by weight of the material obtained in Step 2 and add it, and place it in a constant temperature water bath at 70°C Stir for 2.5 hours, dry and grind to obtain a modified energy storage phase change material;

[0057] Step 4: Weigh 30 parts by weight of the modified energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com