Bridge structural steel and production method thereof

A bridge structure and production method technology, applied in the direction of temperature control, process efficiency improvement, etc., can solve the problem that bridge structural steel cannot meet low temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

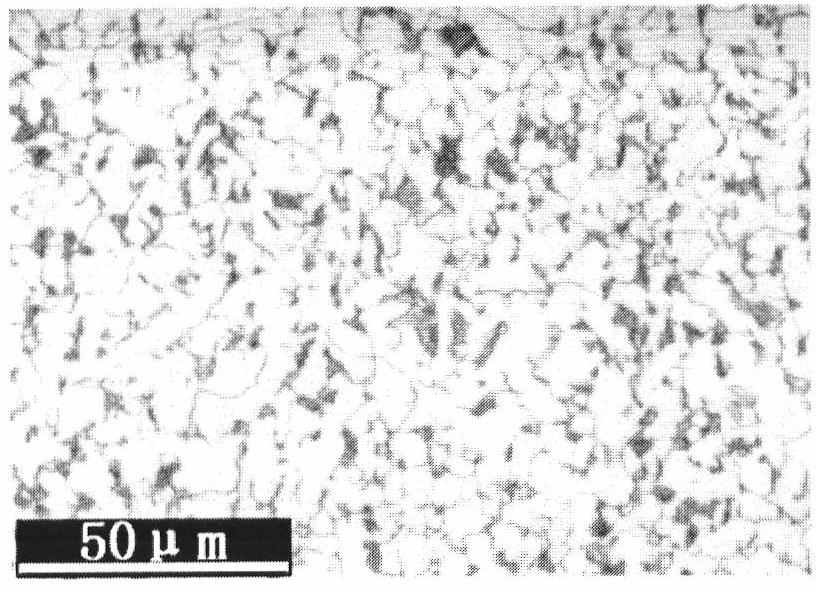

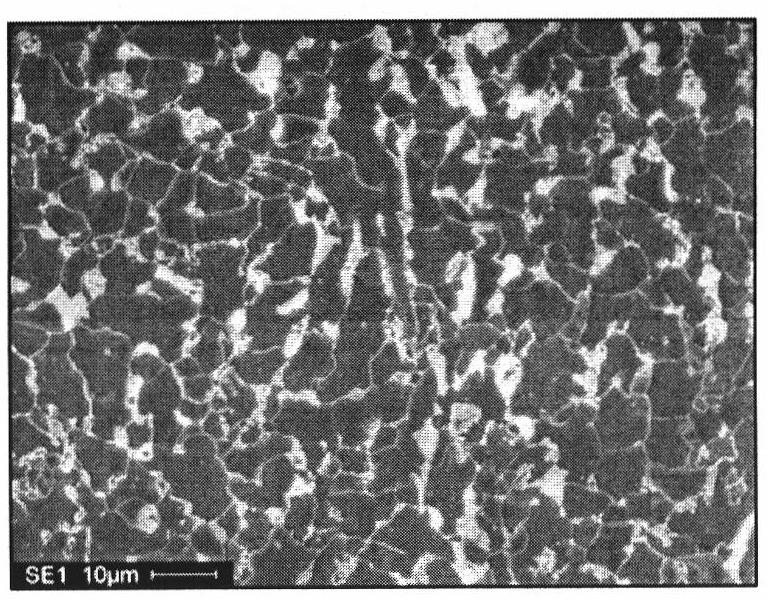

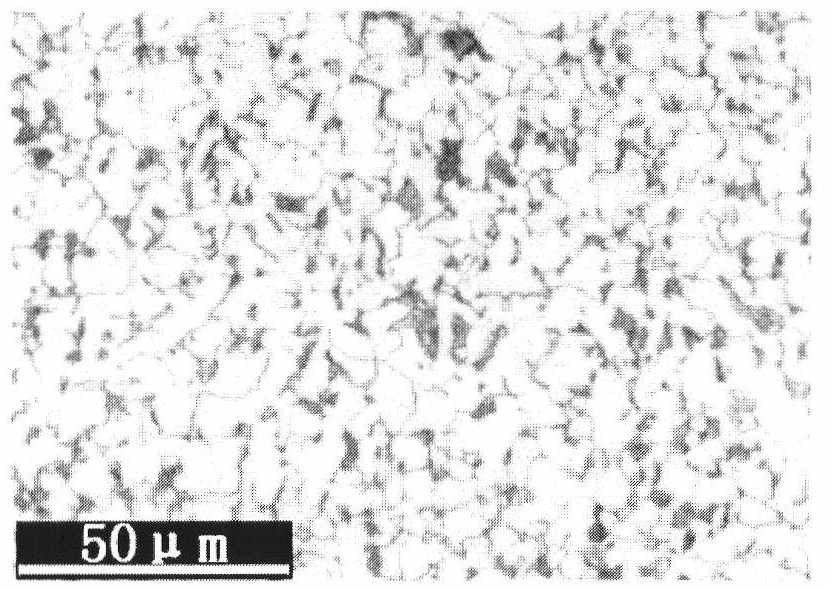

Image

Examples

example 1

[0054] 1. The chemical composition of the bridge structural steel according to Example 1 of the present invention comprises by weight: C: 0.13%, Si: 0.34%, Mn: 1.57%, S: 0.007%, P: 0.015%, Nb: 0.045%, Ti: 0.025%, V: 0.054%, Ni: 0.20%, Als: 0.034%, N≤40×10 -6 , O≤40×10 -6 、H≤2×10 -6 .

[0055] 2, according to the production method of the bridge structural steel of example 1 of the present invention:

[0056] The production process includes molten iron pretreatment, converter smelting with combined top and bottom blowing, LF refining, RH refining, continuous casting of slabs, slow cooling of billets, rolling of 4300mm wide and thick plates, slow cooling of finished products, and normalizing heat treatment. The operation steps are as follows:

[0057] Desulfurization of molten iron strictly follows the process regulations, the sulfur in the molten iron is controlled at 0.008%, the temperature is 1250°C, and the slag on the surface of the molten iron is removed after desulfuri...

example 2

[0063] 1. The chemical composition of the bridge structural steel according to Example 2 of the present invention comprises by weight: C: 0.14%, Si: 0.34%, Mn: 1.41%, S: 0.006%, P: 0.012%, Nb: 0.039%, Ti: 0.017%, V: 0.040%, Ni: 0.19%, Als: 0.024%, N≤40×10 -6 , O≤40×10 -6 、H≤2×10 -6 .

[0064] 2, according to the manufacturing method of the bridge structural steel of example 2 of the present invention:

[0065] The production process includes molten iron pretreatment, top-bottom combined blowing converter smelting, LF refining, RH refining, slab continuous casting, slab slow cooling, 4300mm wide and thick plate rolling, finished product slow cooling, and normalizing heat treatment. The operation steps are as follows:

[0066] Desulfurization of molten iron strictly follows the process regulations, the sulfur in the molten iron is controlled at 0.005%, the temperature is 1267°C, and the slag on the surface of the molten iron is removed after desulfurization. The pretreated ...

example 3

[0072] 1. The chemical composition of the bridge structural steel according to Example 3 of the present invention comprises by weight: C: 0.16%, Si: 0.28%, Mn: 1.40%, S: 0.006%, P: 0.013%, Nb: 0.025%, Ti: 0.021%, V: 0.025%, Ni: 0.15%, Als: 0.030%, N≤40×10 -6 , O≤40×10 -6 、H≤2×10 -6 .

[0073] 2, according to the production method of the bridge structural steel of example 3 of the present invention:

[0074] The production process includes molten iron pretreatment, top-bottom combined blowing converter smelting, LF refining, RH refining, slab continuous casting, slab slow cooling, 4300mm wide and thick plate rolling, finished product slow cooling, and normalizing heat treatment. The operation steps are as follows:

[0075] Desulfurization of molten iron strictly follows the process regulations, the sulfur in the molten iron is controlled at 0.013%, the temperature is 1310°C, and the slag on the surface of the molten iron is removed after desulfurization. The pretreated mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lower yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Lower yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com