Integrated working machine for non-excavation pipeline

A non-excavation, working machine technology, applied in special pipes, pipe components, mechanical equipment, etc., can solve the problems of difficult to ensure work quality, high use cost, high labor intensity, etc., to achieve high-quality pipeline maintenance, high work efficiency , The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Removal of hard scale in the pipe

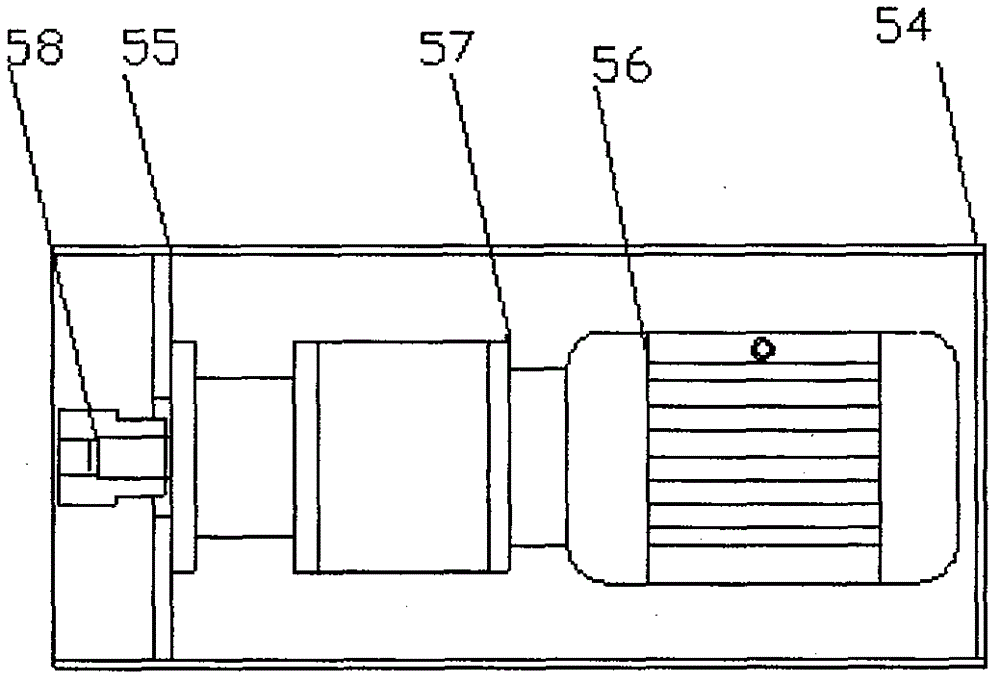

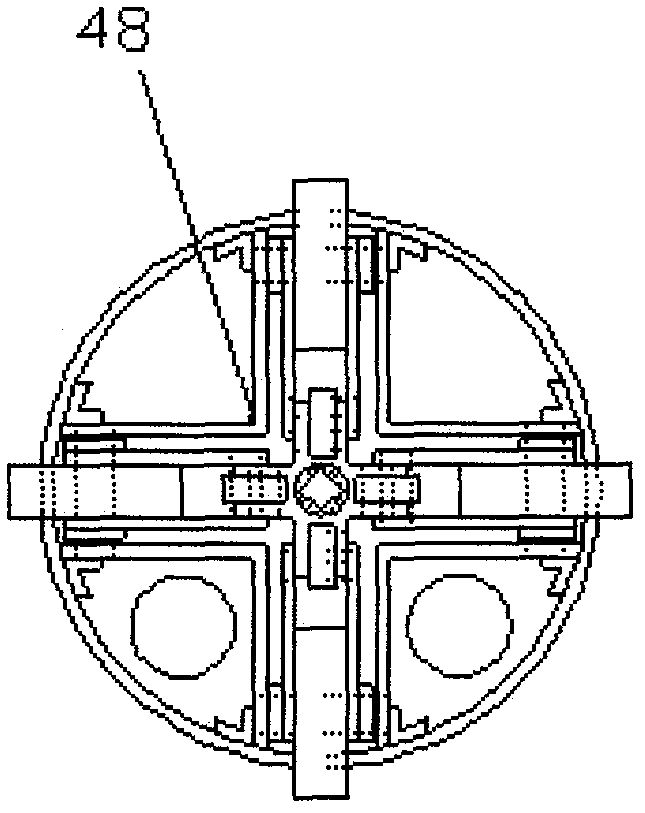

[0042] see figure 1 , figure 2 , Figure 5 , Figure 7 , Figure 8 , Figure 10 In the present invention, six mechanical units including a hard working head, a supporting machine, a pipe wall tensioning machine, a supporting machine, a screw propulsion machine, and a control box are sequentially plugged together and locked by screws to form a comprehensive non-excavation pipeline operation. machine;

[0043] The hard working head includes: the first body 1, the first motor 2 is arranged in the first body 1, the shaft of the first motor 2 passes through the front baffle 3, the sealing ring 4 is connected with the main shaft 5, and the compression nut 8 connects the elastic grinding head 6. The circular grinding head 7 is fixedly installed on the main shaft, and the first motor 2 is connected with the electric control assembly box 62;

[0044] The tube wall tension machine includes: second body 25, tensioner 26, fuel injection pu...

Embodiment 2

[0050] Removal of soft deposits in pipes

[0051] See image 3 , only need to replace the hard working head with the soft working head, the soft working head includes: the sixth body 9, the third motor 10, the sixth body front baffle 11, the main shaft 12, the seal ring 13, the pipe wall brush 14 , cutting head 15, compression nut 16; the sixth body 9 is provided with a third motor 10, the motor 10 is connected to the main shaft 12 through the front baffle plate 11 of the sixth body, and the sealing ring 13 is connected to the control box through a power cable The power line of the electric control assembly box 62 is connected, and the compression nut 16 fixes the cutting head 15 and the pipe wall brush 14 on the main shaft 12.

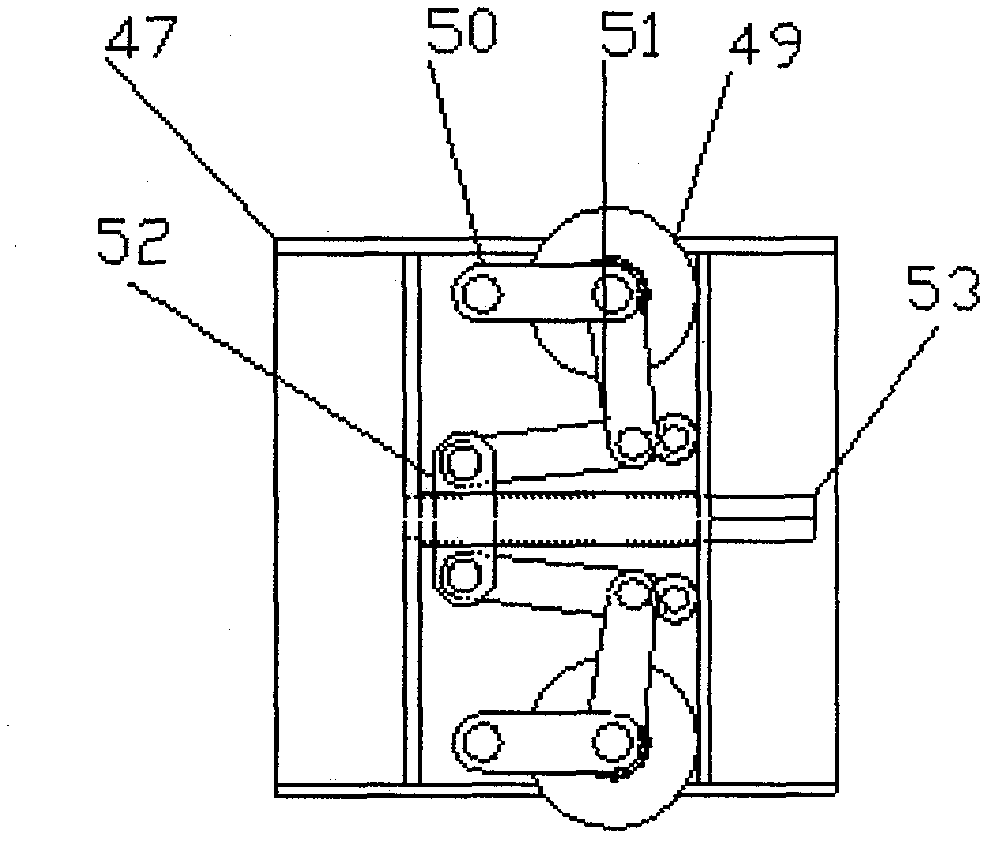

[0052] In the present invention, when it is necessary to remove sand, gravel and soil soft deposits in the pipe, the non-excavation pipeline comprehensive operation machine is placed in the pipe to be pigged, and the transmission screw 53 of the two ...

Embodiment 3

[0054] In-pipe partial maintenance work

[0055] See Figure 4 In the present invention, when local overhaul operations in the pipe or treatment of residual roots in the pipe wall are required, the hard working head of the non-excavation pipeline comprehensive operation machine is replaced by a rotating fixture working head, and the rotating fixture working head includes a seventh body 17 , the fourth motor 18, the biaxial reducer 19, the seventh body front baffle plate 20, the seal ring 22, the rotary fixture 23, the fixture rotating motor 24; the seventh body 17 is provided with the fourth motor 18, the biaxial deceleration Machine 19, the 7th body front baffle 20, the 7th body front baffle 20 inboards are equipped with biaxial reducer 19, the 7th body front baffle 20 outsides are equipped with jig rotating motor 24, jig rotating motor 24 and the The four motors 18 are connected with the power lines of the electric control assembly box 62 in the control box through power ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com