Secondary air premixed gas burner for ceramic kiln

A gas burner and secondary air intake technology, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of small applicability, uncontrollable air intake in the premixing room, failure to maximize energy saving, etc. problem, to achieve the effect of simple and easy operation, which is conducive to full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

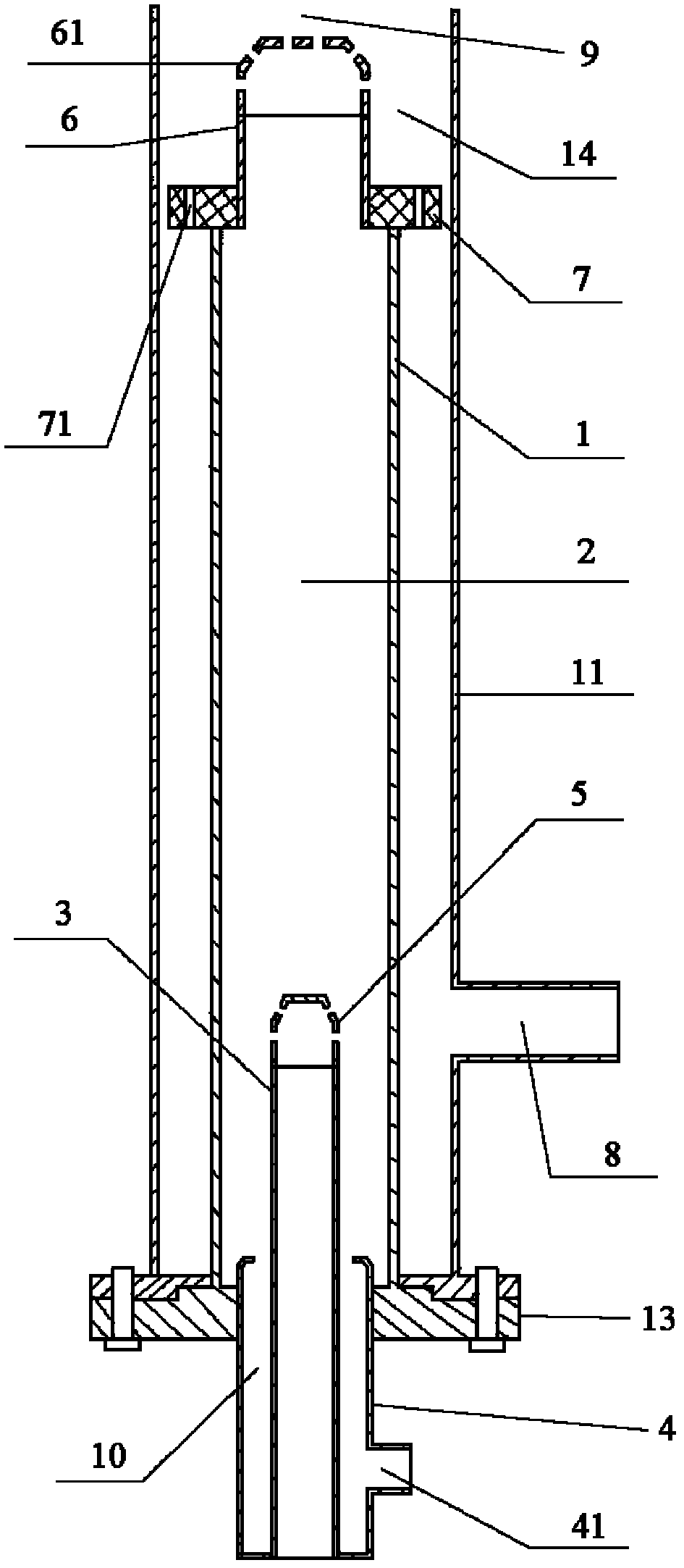

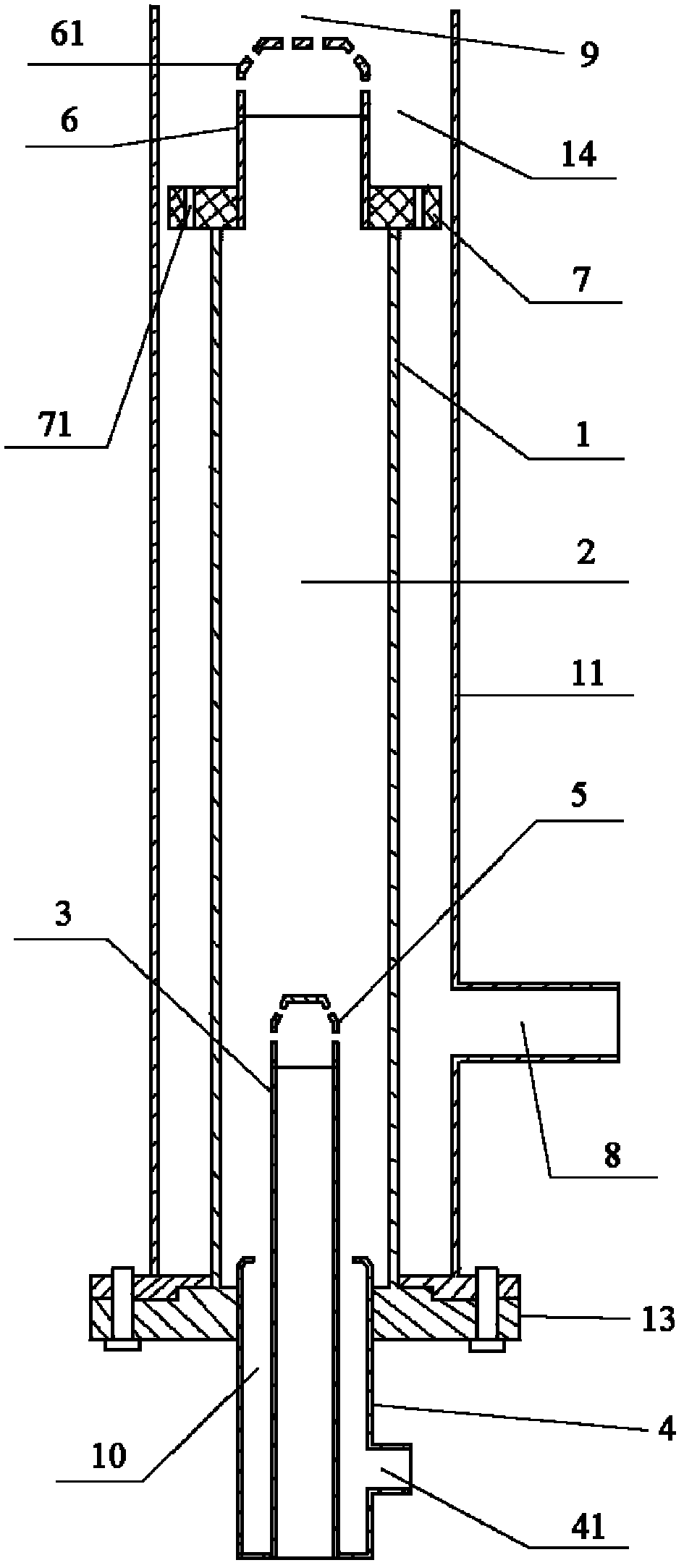

[0016] Such as figure 1 The shown ceramic kiln secondary air intake premixed gas burner includes a shell 1 , a gas pipeline 3 , a secondary air intake pipeline 4 , a combustion nozzle 6 and a support plate 13 . The gas pipeline 3 and the secondary air inlet pipeline 4 are coaxially arranged at one end of the housing 1, the gas pipeline 3 is located in the secondary air inlet pipeline 4, and one end of the gas pipeline 3 protrudes from the secondary air inlet pipeline 4 and enters the inner cavity of the housing 2. A gas diffuser 5 is installed at one end entering the inner cavity 2 of the housing. The gas diffuser 5 is composed of a cylindrical ring plate, a truncated conical ring plate and a baffle connected in sequence. The bottom angle of the truncated circular plate is 45°, and both the cylindrical ring plate and the truncated circular plate are provided with diffusion holes. There is a gap between the gas pipe 3 and the secondary air inlet pipe 4 to form a secondary air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com