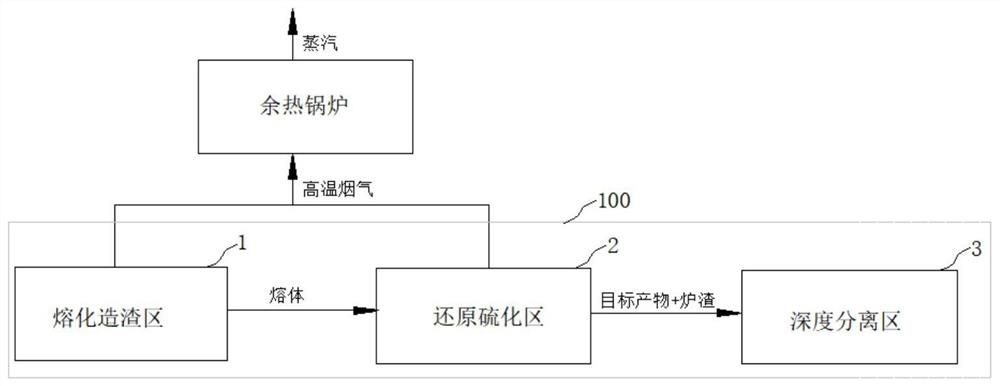

Smelting furnace for smelting nickel matte and production method of low nickel matte

A production method and smelting furnace technology, which are applied to furnaces, charge materials, crucible furnaces, etc., can solve the problems of unpublished proprietary devices, low thermal efficiency process, inability to adapt to continuous production, etc., so as to save heat loss, The effect of reducing heat removal and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

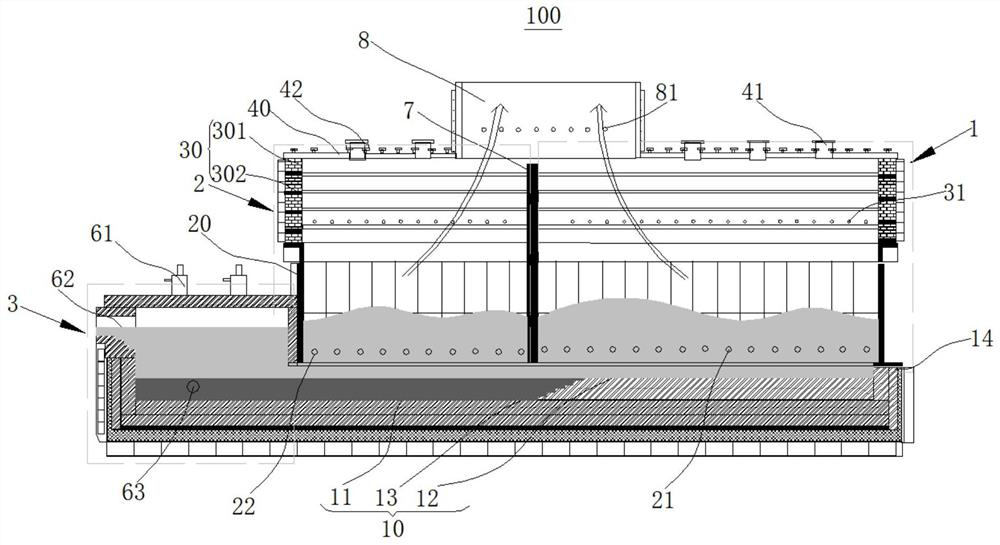

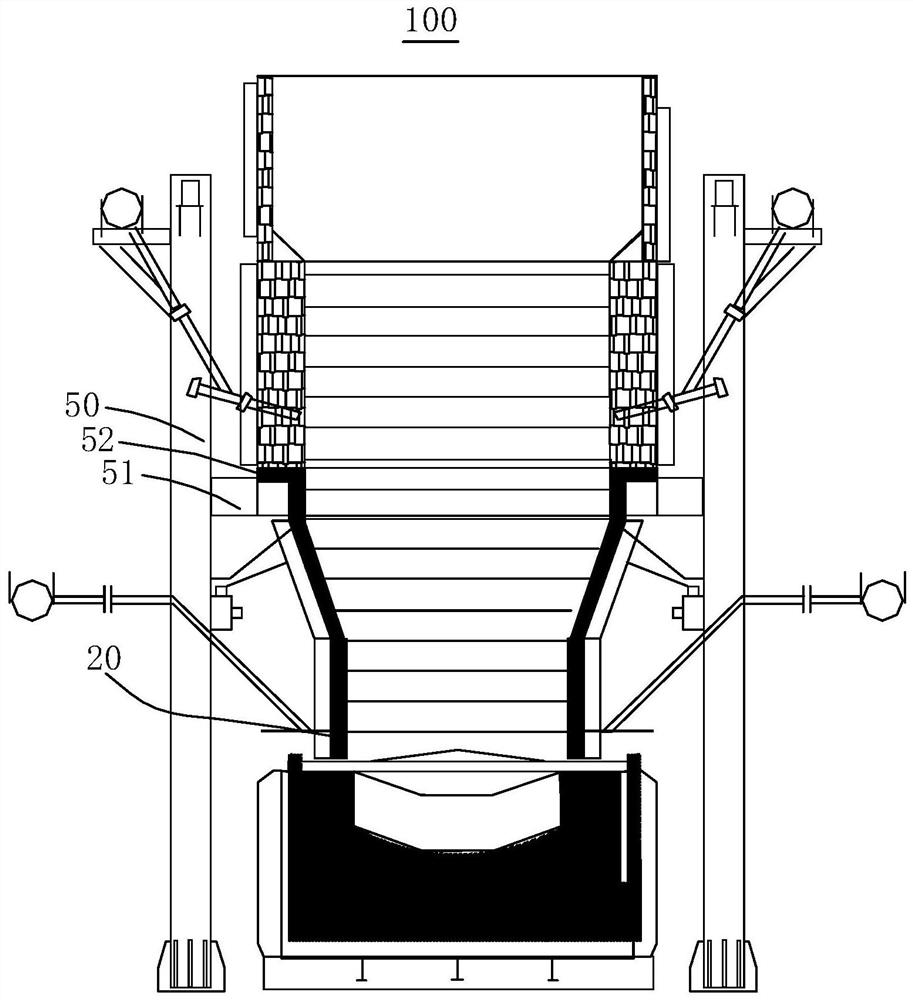

[0120] Put the nickel oxide ore into the drying kiln for drying until the water content is 20% to 25%. After drying, it is sieved through the grid, and the undersize is controlled to be less than 50mm. The dried nickel oxide ore and limestone are fed into the first area 1 of the smelting furnace through the main feeding port 41 of the furnace roof 40 according to a preset ratio, and the oxygen-enriched air and pulverized coal are sprayed into the first area 1 through the first nozzle 21 In the molten pool, the pressure of oxygen-enriched air is 0.12Mpa, the excess coefficient of oxygen-enriched air to fuel is 0.85, the temperature of the first zone 1 is controlled at 1500°C, and the material is rapidly melted and slagged in the stirred molten pool under a weak reducing atmosphere. Melt is formed; the melt produced in the first area 1 continuously flows into the second area 2 through the lower channel of the partition wall, and the reducing agent pulverized coal, sulfiding agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com