Full vacuum flat-plate solar collector

A flat-panel solar energy and heat collector technology, which is applied to solar heat collectors, solar heat collectors using working fluids, solar thermal energy, etc., can solve problems such as excessive volume, low thermal efficiency, and difficulty in assembling and improving Thermal efficiency, compact structure, and the effect of solving glass bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

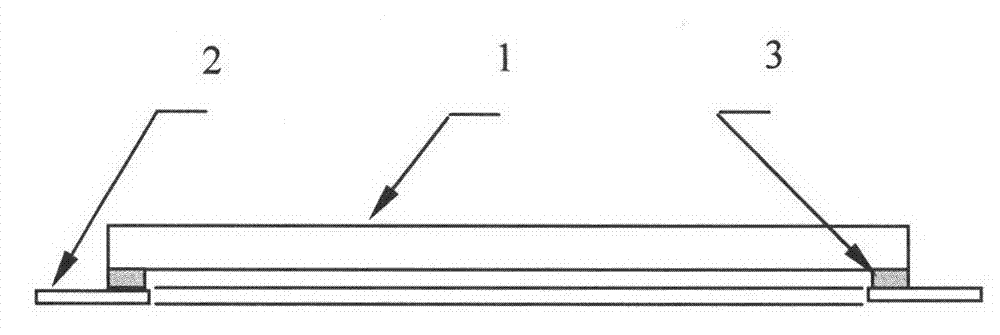

[0033] Depend on figure 1 It can be seen that the glass used in the present invention is provided with a solid metal strip 2 on the glass 1 , and the metal strip 2 extends outward beyond the edge of the glass 1 . In this embodiment, the glass 1 is made of lead-free glass with good light transmittance, and the glass and the metal strip 2 are bonded together through low-melting point glass.

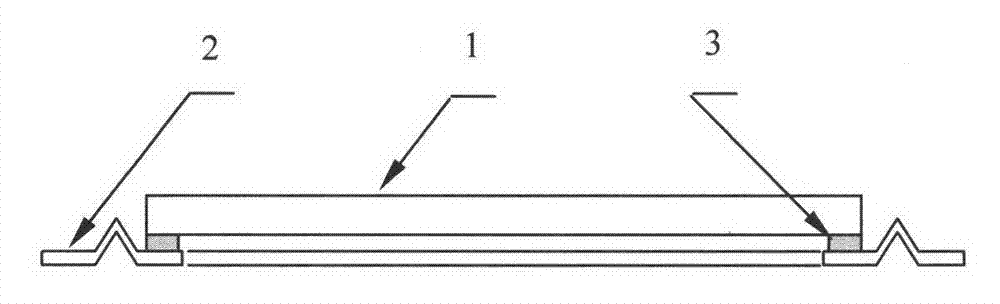

[0034] figure 2 and figure 1 The difference is that a section of metal strip 2 that extends beyond the glass 1 contains an energy absorbing zone and a welding zone, the welding zone is located at the outer end of the metal strip, and the energy absorbing zone is located between the welding zone and the edge of the glass. The area is in the shape of a broken line.

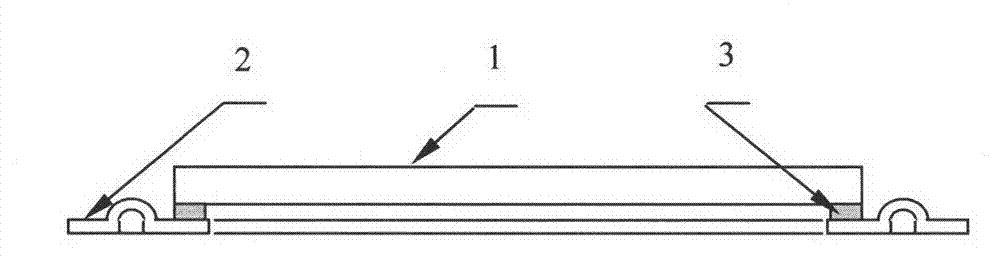

[0035] image 3 and figure 2 The difference is that the energy absorbing area is corrugated.

[0036] Figure 4 and figure 2 The difference is that the energy absorption area is another form of broken line. Visible by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com