Rotating motor, electric pressure fan and device

A technology of rotating motors and rotating shafts, applied in mechanical equipment, machines/engines, non-variable pumps, etc., can solve problems such as uncontrollable costs, inconsistent characteristics, and no improvement in losses, so as to reduce material costs and reduce material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

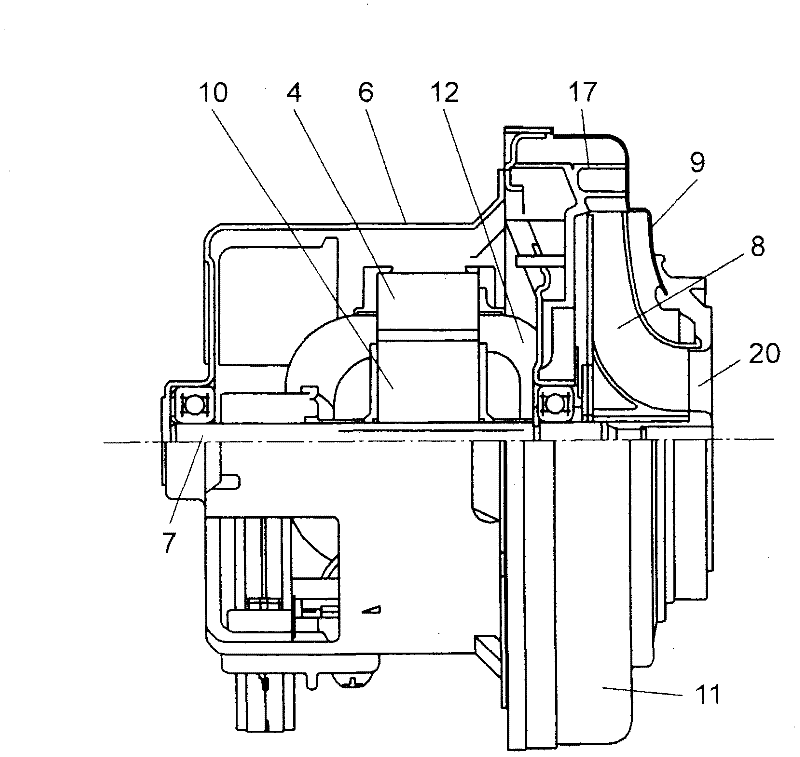

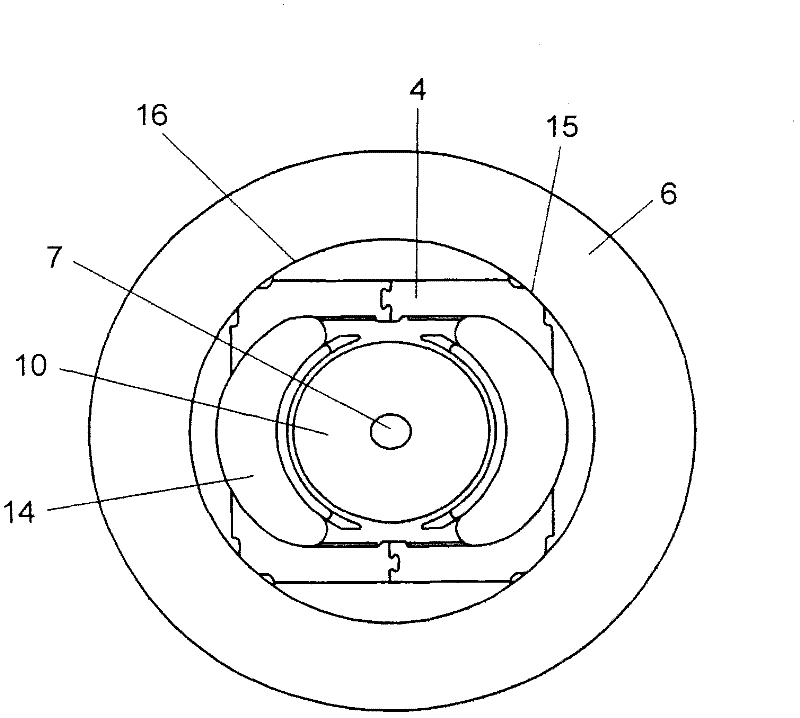

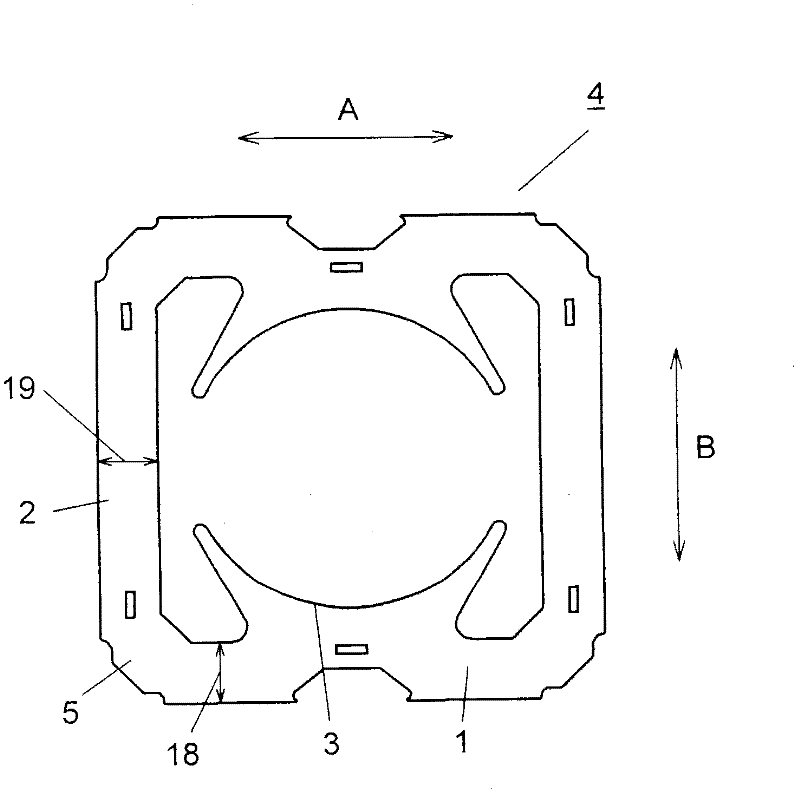

[0023] Hereinafter, an electric blower using a rotating electrical machine according to an embodiment of the present invention will be described with reference to the drawings.

[0024] figure 1 It is a partial sectional view showing the structure of the electric blower according to the embodiment of the present invention, figure 2 It is a partial cross-sectional view showing a state in which a field magnet is pressed into a bracket of an electric blower according to an embodiment of the present invention, image 3 It is an explanatory diagram showing a field core in which a salient pole portion is provided on a frame formed in the steel sheet rolling direction.

[0025] exist Figure 1 ~ Figure 3 Among them, the electric blower 11 is provided with a rotating motor in a cylindrical bracket 6 that closes the opening in the opposite direction on one side. The rotating electric machine is roughly constituted by a field magnet 12 and an armature 10 . The field magnet 12 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com