Self-control oxygen-charging fermentation method for black tea

A fermentation method and oxygenation technology, which is applied in the field of self-controlled oxygenation fermentation of black tea, can solve the problems of insufficient oxidation, long fermentation time of fresh tea leaves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

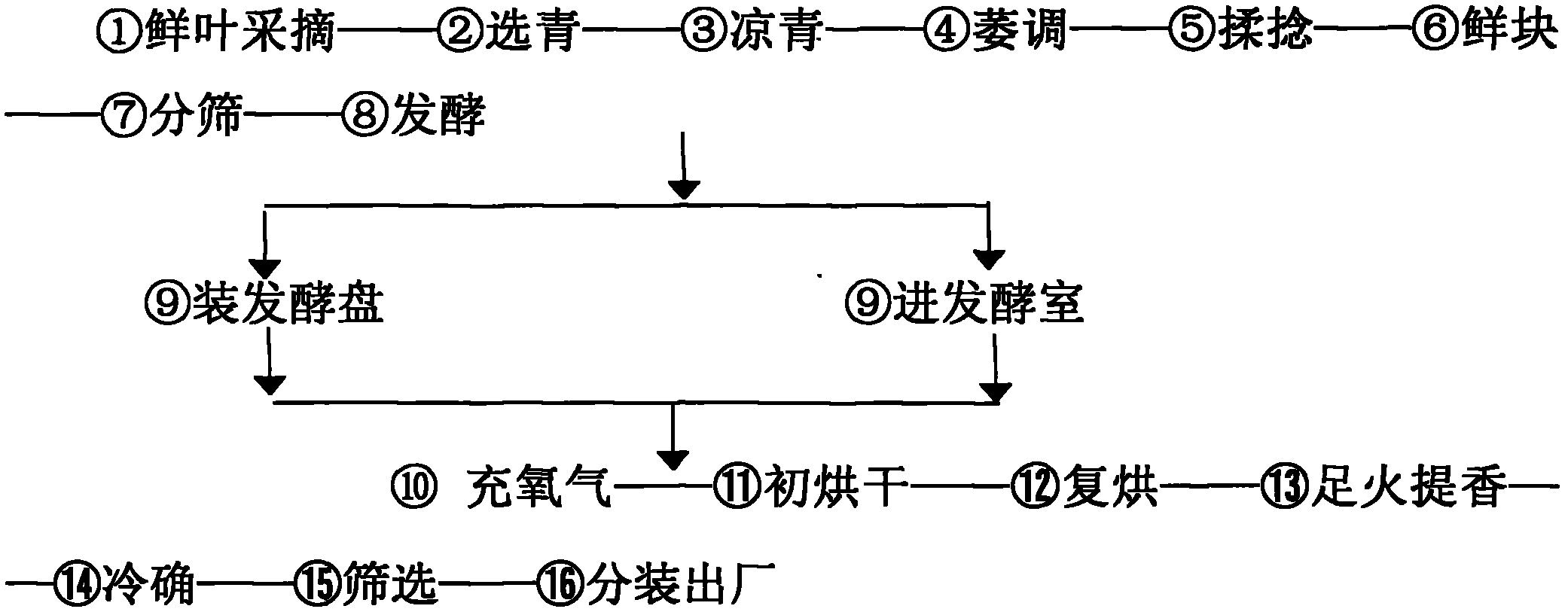

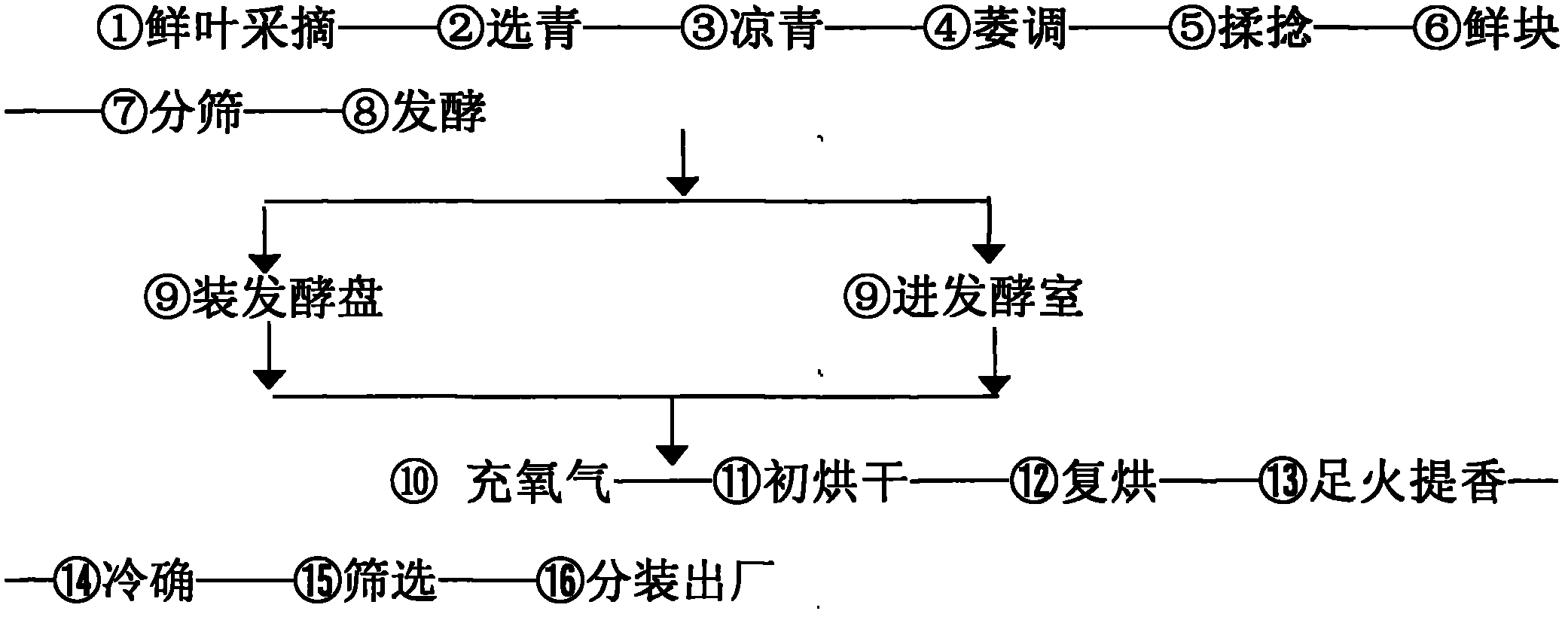

[0012] Traditional black tea processing methods are made by machine or by hand. Hand processing is used for high quality tea leaves. Traditional methods use different methods according to different tea leaves. This processing style is to meet the needs of various customers in the market. After the collected fresh tea leaves are withered and rolled, the leaves are oxidized under controlled temperature and humidity. This process is also called fermentation. The level of tea oxidation determines the quality of the tea, and since oxidation begins during the rolling stage, the length of time between the two stages is also a crucial factor for the quality of the tea. The present invention is developed aiming at the fermentation stage of the black tea in the processing process, and obtains a set of new black tea self-controlled aerobic fermentation method.

[0013] The technical process of the black tea self-controlled aerobic fermentation method is:

[0014] a) deblocking and sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com