Baking automobile finish with high solid content and preparation method thereof

An automotive topcoat, high-solid technology, used in polyester coatings, coatings, etc., can solve the problems of long drying time, water-based intermediate coatings and water-based topcoats that have not been industrially applied, and achieve full paint film and natural exposure performance. Excellent, less organic solvent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

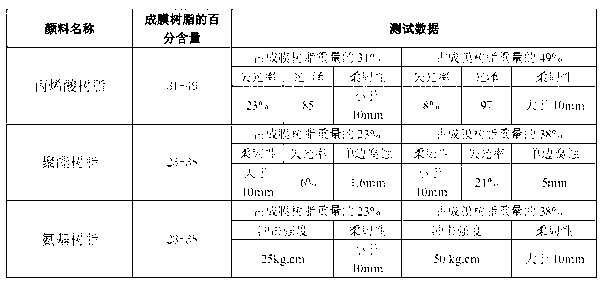

Image

Examples

Embodiment 1

[0040] Embodiment 1: prepare 1 ton of high-solid content drying automobile finish, at first take by weighing the acrylic resin 270Kg, 15% pigment phthalocyanine blue 150Kg, 9% of high-solid content drying automobile finish gross mass 27% 90Kg of xylene, 2Kg of 0.2% BYK-300, 4Kg of 0.4% BYK-110, 4Kg of 0.4% dibutyltin dilaurate, put all the raw materials into a high-speed mixer for pre-mixing, and pre-mix Good raw materials are pre-grinded and dispersed in a grinder; then weigh 190Kg of polyester resin, 190Kg of 19% amino resin, 90Kg of 9% xylene, and 0.2% BYK-300 is 2Kg, 0.4% BYK-110 is 4Kg, 0.4% dibutyltin dilaurate is 4Kg, mixed with the aforementioned ground and dispersed raw materials, mixed thoroughly, and filtered to obtain the desired one High solids drying automotive finish.

[0041] The implementation steps of embodiment 2 to embodiment 5 are as described in embodiment 1. The high-solid content drying automobile topcoat of 1 ton is produced, and the required raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com