Heat supply device for high-frequency eddy pipeline

A technology for heating devices and pipes, applied in induction heating devices, fluid heaters, induction heating, etc., can solve the problems of low thermal efficiency, power consumption, long preheating time, etc., to extend service life, save energy, preheat The effect of shortening time

Inactive Publication Date: 2011-10-05

陈勇青

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The existing metal pipeline system, because the internal liquid will freeze at low temperature, or the internal scale and microbial film will be generated when it is used for a long time, so a heating device is required. Generally, a resistance heater is used. The thermal efficiency of the device is low, and the preheating time is long. Electricity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

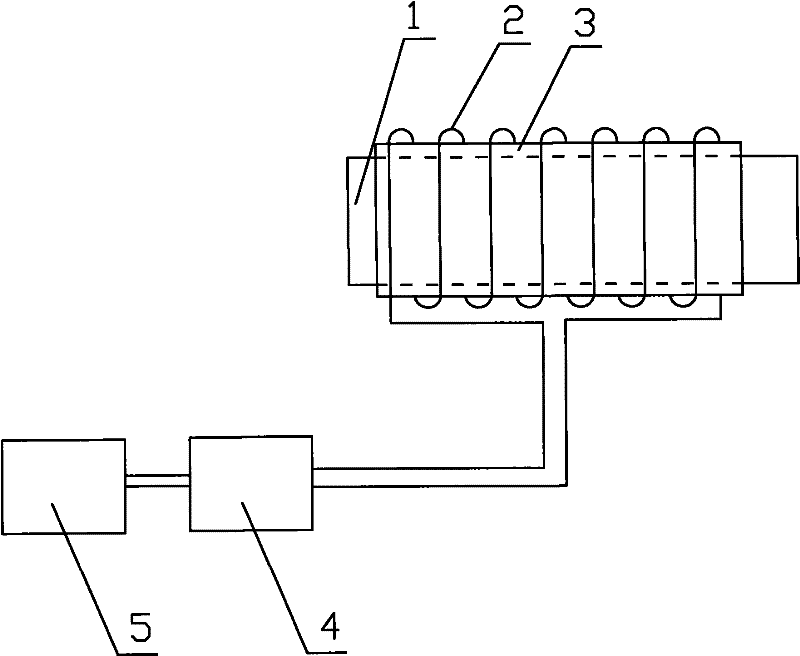

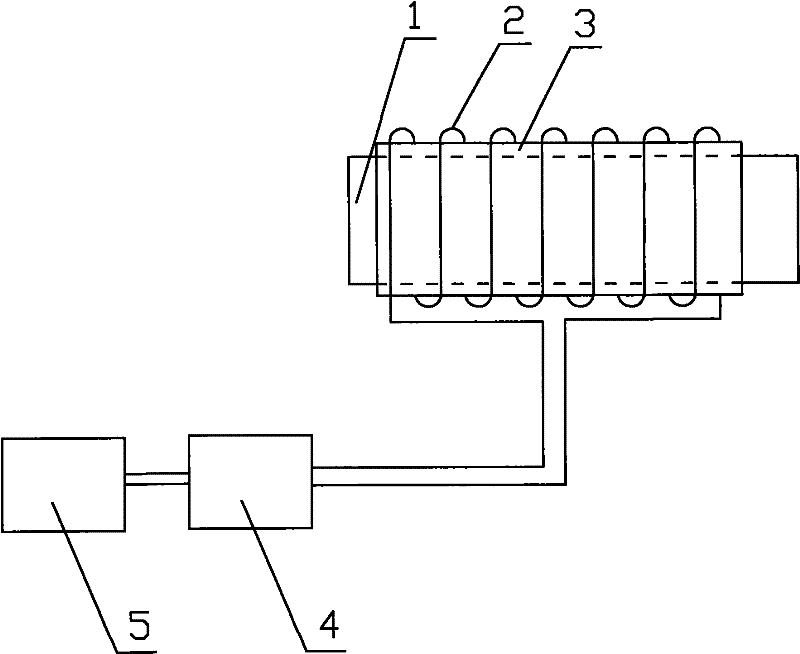

[0009] Such as figure 1 As shown, the high-frequency eddy current pipeline heating device includes a pipeline 1, a coil 2 is wound on the pipeline 1, an insulation layer 3 is arranged between the pipeline 1 and the coil 2, the coil 2 is electrically connected to the inverter circuit 4, and the inverter circuit 4 is electrically connected to the rectifier circuit 5.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a heat supply device for a high-frequency eddy pipeline, and belongs to the technical field of electric heating. The heat supply device comprises a pipeline, wherein a coil is wound on the pipeline; an insulating layer is arranged between the pipeline and the coil; the coil is electrically connected with an inverter circuit; and the inverter circuit is electrically connected with a rectification circuit. In the heat supply device, the heat efficiency is more than 95 percent, the preheating time is shortened by 2 / 3, and compared with a resistance-type heating device, the heat supply device saves electricity by more than 25 percent under the same condition. The heat supply device can prevent scales and microbial membranes, prolong the service life, prevent the pollution of chemical cleaning to environment and save energy.

Description

technical field [0001] The invention belongs to the technical field of electric heating, and in particular relates to a high-frequency eddy current pipeline heating device. Background technique [0002] The existing metal pipeline system, because the internal liquid will freeze at low temperature, or the internal scale and microbial film will be generated when it is used for a long time, a heating device is required, and a resistance heater is generally used. The thermal efficiency of the device is low, and the preheating time is long. Electricity. Contents of the invention [0003] The object of the present invention is to provide a high-frequency eddy current pipeline heating device with high thermal efficiency, short preheating time, environmental protection and energy saving. [0004] The object of the present invention is achieved in this way: the high-frequency eddy current pipeline heating device includes a pipeline, a coil is wound on the pipeline, an insulation l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F24H1/00H05B6/10

Inventor 陈勇青

Owner 陈勇青

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com