Automatic detection method of static contact angle and dynamic contact angle

A technology of static contact angle and dynamic contact angle, which is used in measuring devices, instruments, scientific instruments, etc., can solve the problems of doubling the workload and calculation time, and achieve the effect of high accuracy, high calculation accuracy, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

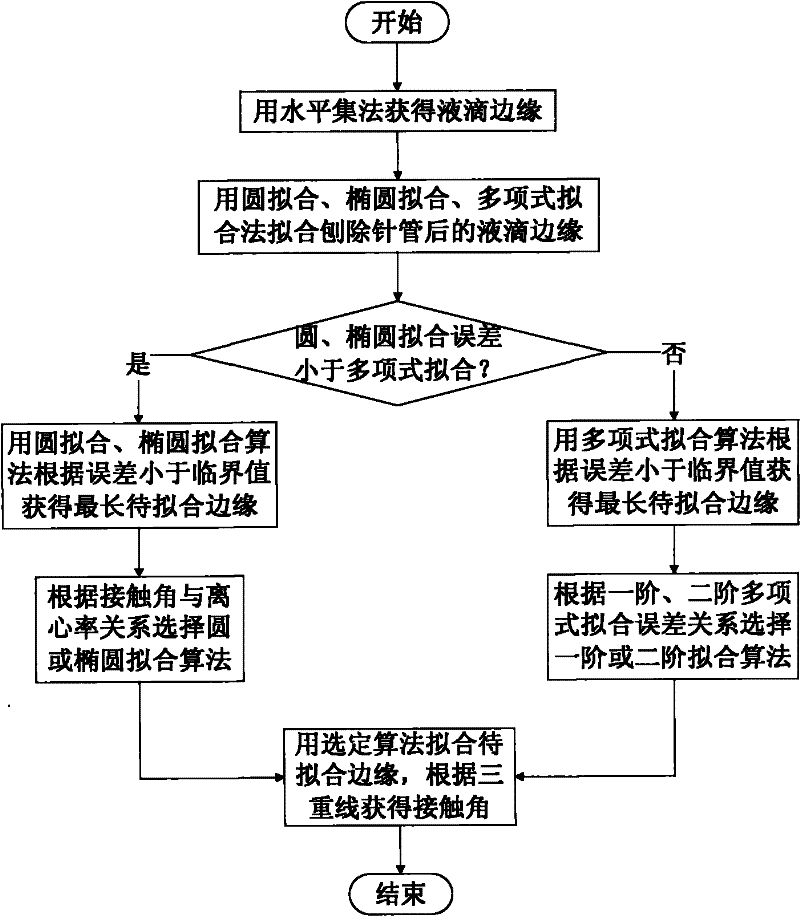

[0027] See attached figure 1 , the steps of applying the present invention are:

[0028] (1) Use a digital camera or a CCD camera in combination with an image acquisition card to take pictures of the water droplets on the material, and the camera plane is perpendicular to the material plane;

[0029] (2) The obtained water drop image is obtained based on the level set method to obtain the water drop edge;

[0030] (3) According to the circle, ellipse fitting and polynomial fitting, the edge of the droplet near the needle tube is fitted, and the error is judged as the static contact angle, the image of the advancing angle or the image of the receding angle. If the former is smaller than the latter, it is static contact angle or advancing angle image; otherwise receding angle image;

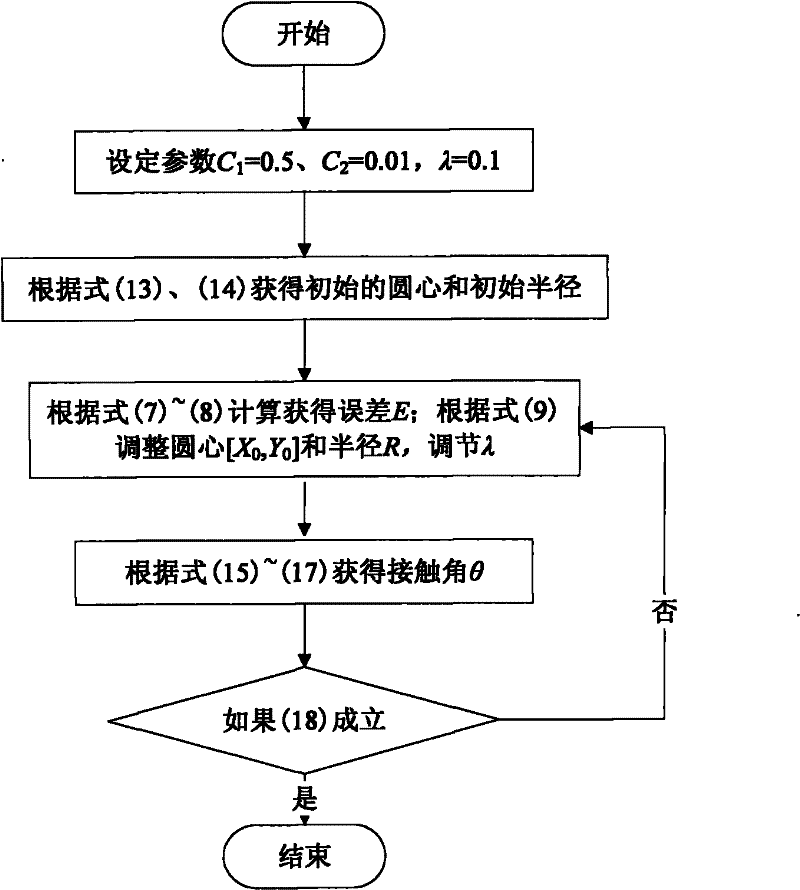

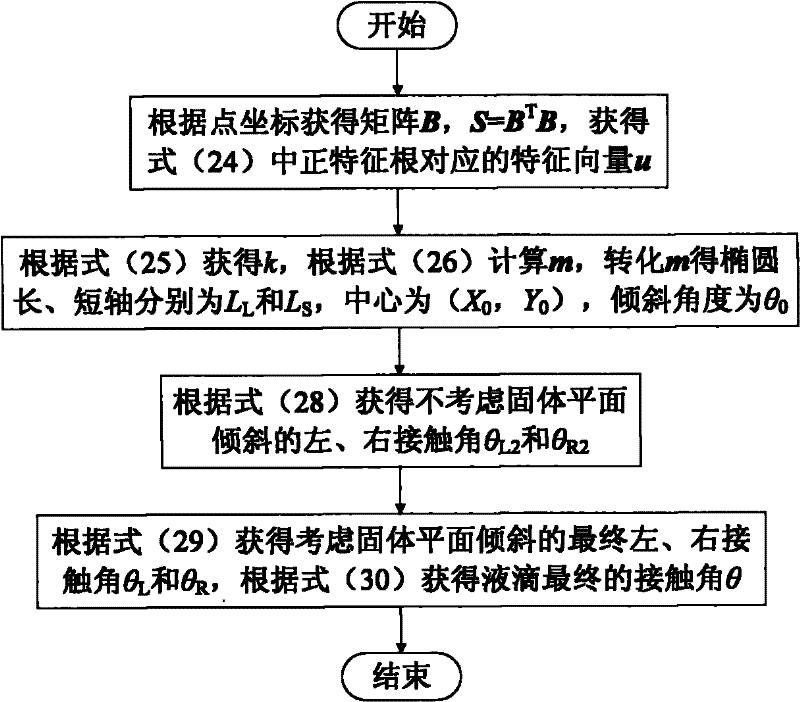

[0031] (4) When calculating the static contact angle or advancing angle, select the circle fitting method or the ellipse fitting method, select the edge to be fitted according to the fitting erro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com