Polarization element and manufacturing method thereof

A polarizing element and carbon nanotube film technology, applied in optical elements, polarizing elements, optics, etc., can solve the problems of the polarizing element losing the polarization effect, the humidity requirement of the polarizing element, and the inability to uniformly polarize and absorb electromagnetic waves. Effect of range, uniform polarization absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

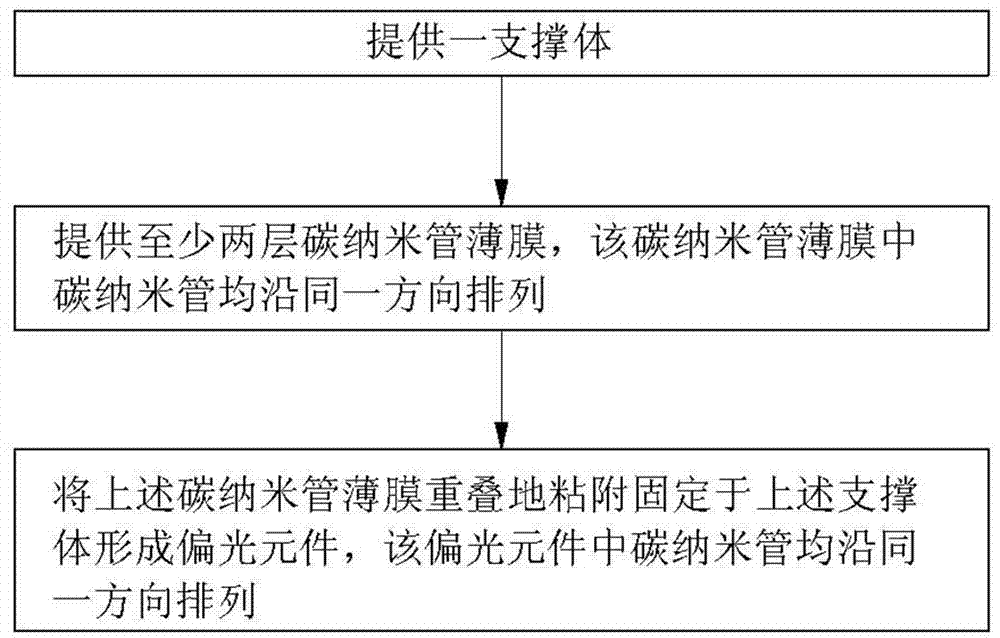

[0026] See figure 2 The preparation method of the polarizing element 10 of the embodiment of the present invention mainly includes the following steps:

[0027] Step 1: Provide a carbon nanotube array. Preferably, the array is a super-in-line carbon nanotube array.

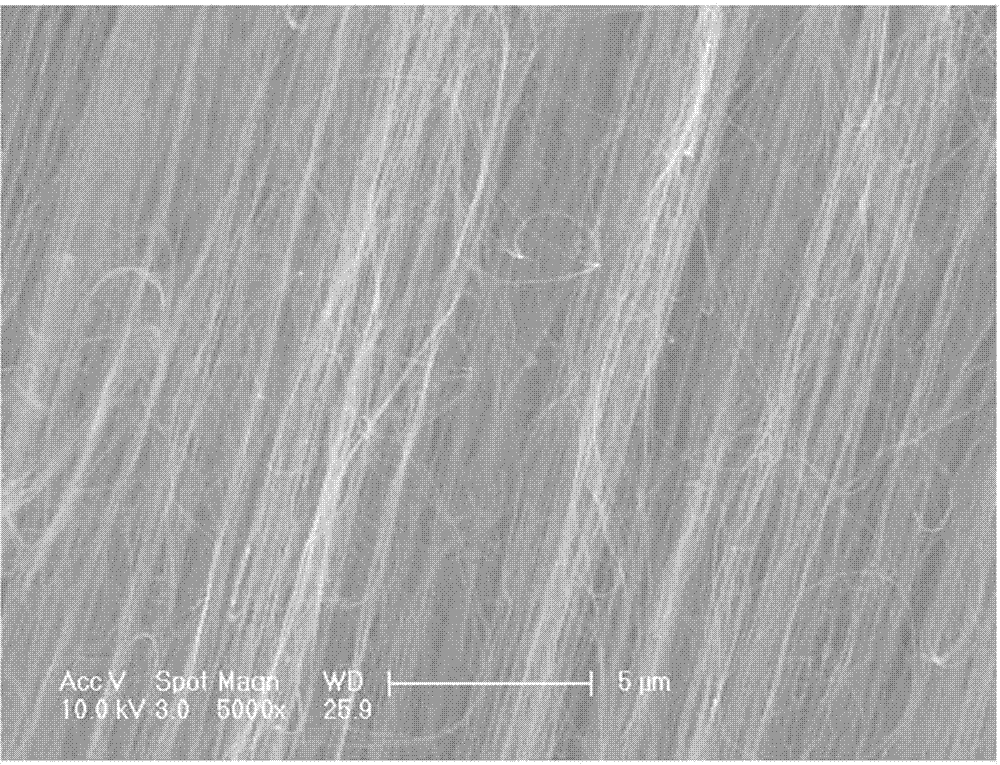

[0028] In this embodiment, the preparation method of the super in-line carbon nanotube array adopts the chemical vapor deposition method, and the specific steps include: (a) providing a flat substrate. The substrate can be a P-type or N-type silicon substrate, or a silicon substrate formed with The silicon substrate of the oxide layer is preferably a 4-inch silicon substrate in this embodiment; (b) a catalyst layer is uniformly formed on the surface of the substrate, and the catalyst layer material can be iron (Fe), cobalt (Co), nickel (Ni) Or one of the alloys of any combination thereof; (c) annealing the substrate with the catalyst layer formed in the air at 700-900°C for about 30 minutes to 90 minutes; (d) placing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com