Preparation method of wear-resistant and anti-locking ni-agpd composite coating on the surface of aviation bolts

A composite coating, anti-locking technology, applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve problems such as incompatibility, achieve strong adhesion, good thread seizure, flight life prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

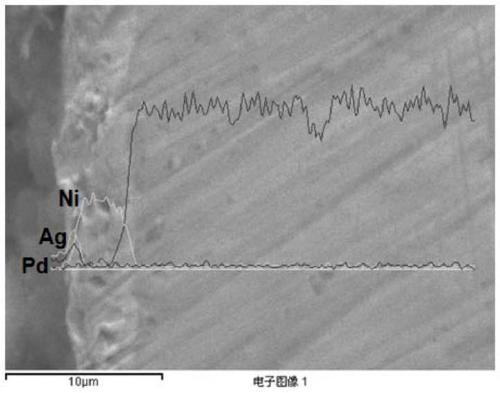

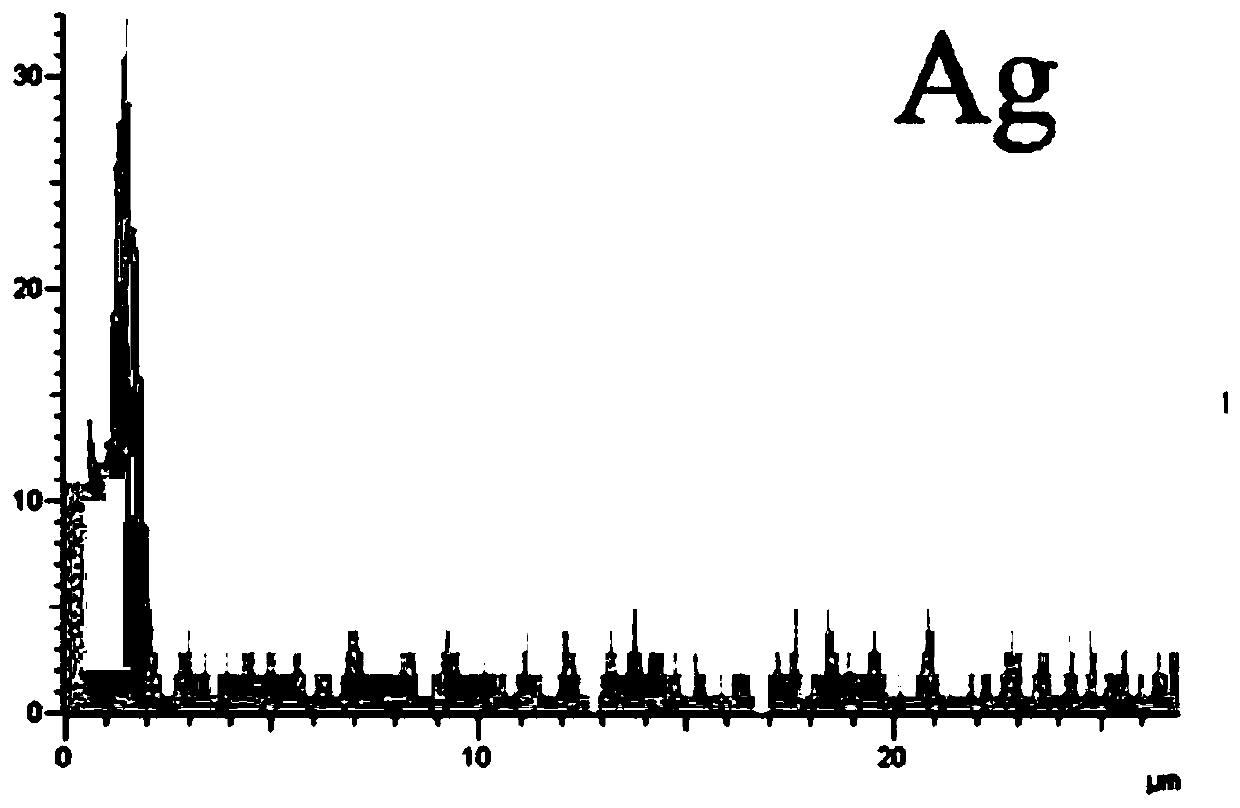

Image

Examples

Embodiment 1

[0027] The preparation method of the present embodiment comprises the following steps:

[0028] Step 1. Bolt polishing and cleaning: Use a vibration polishing machine to vibrate and polish the bolts. The time of vibration polishing is 15 minutes, and then use industrial degreasing agent, absolute ethanol and deionized water to perform ultrasonic cleaning in sequence. The time of each cleaning is the same. During the ultrasonic cleaning process, the temperature is controlled at 15°C to 40°C; during vibration polishing, add polishing liquid and white corundum balls with a diameter of 0.5mm to the vibratory polishing machine. The polishing liquid matches the threaded surface of the polished bolt, and the polishing liquid is an alumina polishing liquid; the time of vibration polishing is 15 minutes; the mass ratio of the white corundum ball to the alumina polishing liquid is 10:1; the bolt is for aviation TC4 titanium alloy bolts; the industrial degreaser is a common commercially ...

Embodiment 2

[0035] The preparation method of the present embodiment comprises the following steps:

[0036] Step 1. Bolt polishing and cleaning: Use a vibration polishing machine to perform vibration polishing on the bolts. The vibration polishing time is 20 minutes, and then use industrial degreasing agent, absolute ethanol and deionized water to perform ultrasonic cleaning in sequence. During the ultrasonic cleaning process, the temperature is controlled at 15°C to 40°C; when vibrating polishing, add polishing liquid and white corundum balls with a diameter of 3mm to the vibrating polishing machine. Liquid cooperates the threaded surface of polishing bolt, and described polishing liquid is diamond polishing liquid; The mass ratio of described white corundum ball and diamond polishing liquid is 10:1; Described bolt is aviation TC11 titanium alloy bolt; The industrial degreasing The degreaser is a common commercially available degreaser;

[0037] Step 2, thread sandblasting: perform sand...

Embodiment 3

[0051] The preparation method of the present embodiment comprises the following steps:

[0052] Step 1. Bolt polishing and cleaning: Use a vibration polishing machine to vibrate and polish the bolts. The time of vibration polishing is 30 minutes, and then use industrial degreasing agent, absolute ethanol and deionized water to perform ultrasonic cleaning in sequence. The time of each cleaning is the same. During the ultrasonic cleaning process, the temperature is controlled to be 15°C to 40°C; when vibrating polishing, add polishing liquid and white corundum balls with a diameter of 5mm to the vibrating polishing machine, and the white corundum balls are used as the abrasive material of the vibrating machine. Polishing fluid matches the threaded surface of the polished bolt, and the polishing fluid is an alumina polishing fluid; the mass ratio of the white corundum ball and the alumina polishing fluid is 10:1; the bolt is a 316 stainless steel bolt for aviation; the industrial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com