A kind of organic/inorganic phenolic resin hybrid aerogel and preparation method thereof

A phenolic resin and aerogel technology, which is applied in the fields of organic/inorganic phenolic resin hybrid aerogel and its preparation, porous hybrid phenolic resin aerogel and its preparation field, can solve the problem of anti-oxidation and anti-oxidation of heat-proof composite materials. Insufficient scouring ability, reducing the weight of aircraft heat-resistant materials, poor skeleton strength, etc., to achieve the effects of good thermal insulation efficiency, good oxidation resistance, and high carbonized structure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A kind of preparation method of organic / inorganic phenolic resin hybrid airgel, the steps are:

[0043] (1) prepare silica sol, the mass concentration of solute in the prepared silica sol is 10%-40%;

[0044] (2) prepare phenolic resin sol, the mass concentration of solute in the prepared phenolic resin sol is 10%-50%;

[0045] (3) Add the silica sol prepared in step (1) to the phenolic resin sol prepared in step (2), then add a weak base catalyst or curing agent, and stir at room temperature for 10-60 minutes until a clear and transparent solution is obtained;

[0046](4) Seal the clear and transparent solution obtained in step (3), then carry out a sol-gel (co-gel) chemical reaction at a temperature of 60-150° C. for 4-120 hours, and dry the product after the reaction is completed to obtain organic / Inorganic phenolic resin hybrid airgel.

[0047] In the described step (1), the method for preparing silica sol is: hydrolyzing tetraethyl orthosilicate solution, tetra...

Embodiment 1

[0073] Embodiment 1 (blank control example, the preparation of pure phenolic resin airgel and lightweight anti-heat insulation composite material):

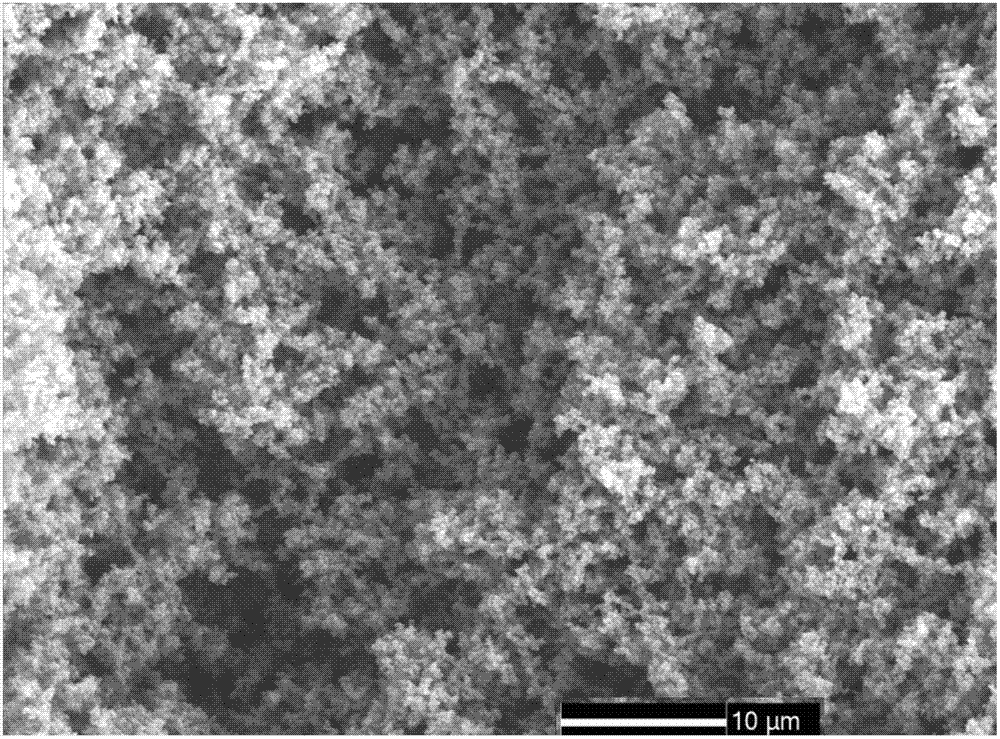

[0074] Weigh 500g of novolak resin and dissolve it in 2286g of ethanol solvent, add 71.43g of HTMA, stir and mix until it dissolves evenly, pour it into a molding mold, seal it and cure it at 120°C for 6 hours. After the reaction was completed, the wet gel was taken out, left to air at room temperature for one day, and then dried in an oven at 50°C under normal pressure for 2 days to obtain a dry pure phenolic resin airgel. The microscopic morphology of the obtained pure phenolic resin airgel is as follows figure 1 shown by figure 1 It can be seen that the phenolic resin airgel presents a porous morphology.

Embodiment 2

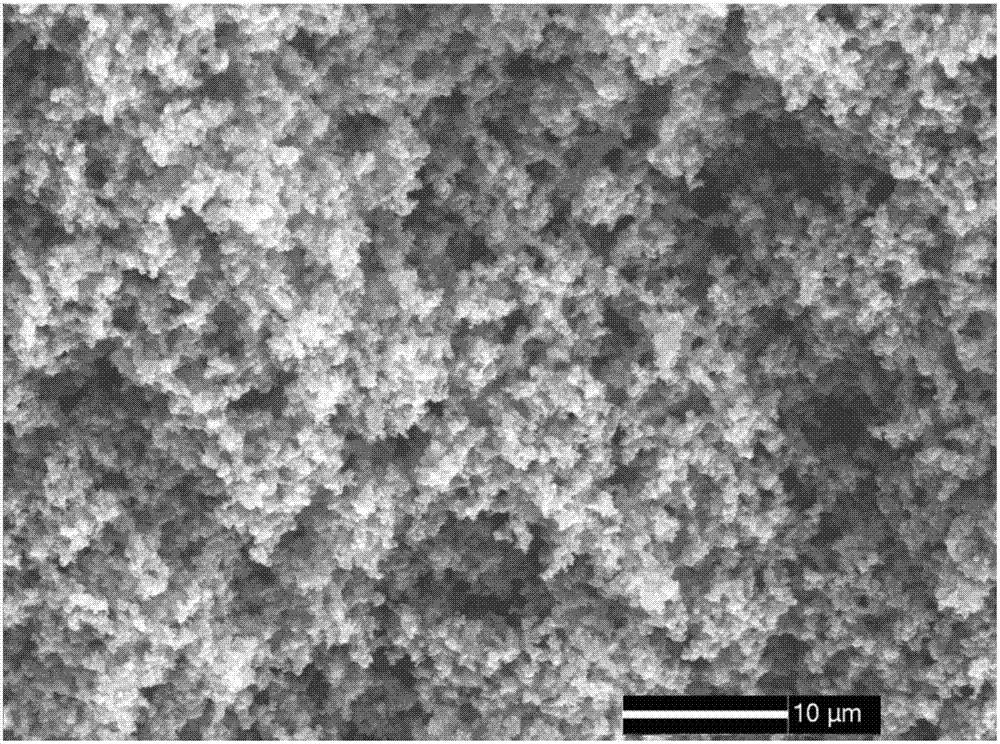

[0076] Weigh 3.95g TEOS and add it to 15.80g ethanol solvent, then add 0.6826g of 0.1mol / L dilute nitric acid, stir at room temperature, and hydrolyze for 30min to prepare a silica sol with a mass fraction of 20% for later use. Weigh 15.25g of novolac resin and 1.92g of hexamethylenetetramine catalyst, pour it into a container, weigh 4.00g of TEOS solution with a mass fraction of 20%, add it to the phenolic resin, and then add 57.60g of ethanol solvent to keep The mass fraction of the novolak resin is 20%, sealed, and cured at 120° C. for 5 hours. After the reaction was completed, the wet gel was taken out, dried at room temperature for 1 day, and then dried in an oven at 50°C for 20 hours to obtain SiO 2 The hybrid airgel with a mass content of 5%, the microscopic morphology of the obtained hybrid airgel is as follows figure 2 shown by figure 2 It can be seen that the hybrid airgel still presents a porous morphology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com