Upper deburring machine for continuous casting slab

A technology of deburring machine and slab, applied in the field of continuous casting slab deburring machine, can solve the problems of difficult to master surfacing welding technology, low blade service life, and reduced adhesion between the blade and the surface of the billet, etc., which is beneficial to equipment maintenance and security. Product performance, the effect that is conducive to product maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The deburring machine is a special equipment for removing the steel slag on the gas cutting edge of the steel billet on the steelmaking production line.

[0024] 1. The current status of the deburring machine:

[0025] At present, all steel mills do not deal with the burrs on the upper surface of the slab, but as the rolling mills have higher and higher requirements on the quality of the slab, it is increasingly important to clean the burrs on the upper surface of the slab

[0026] 2. The structure of the deburring machine (with photos):

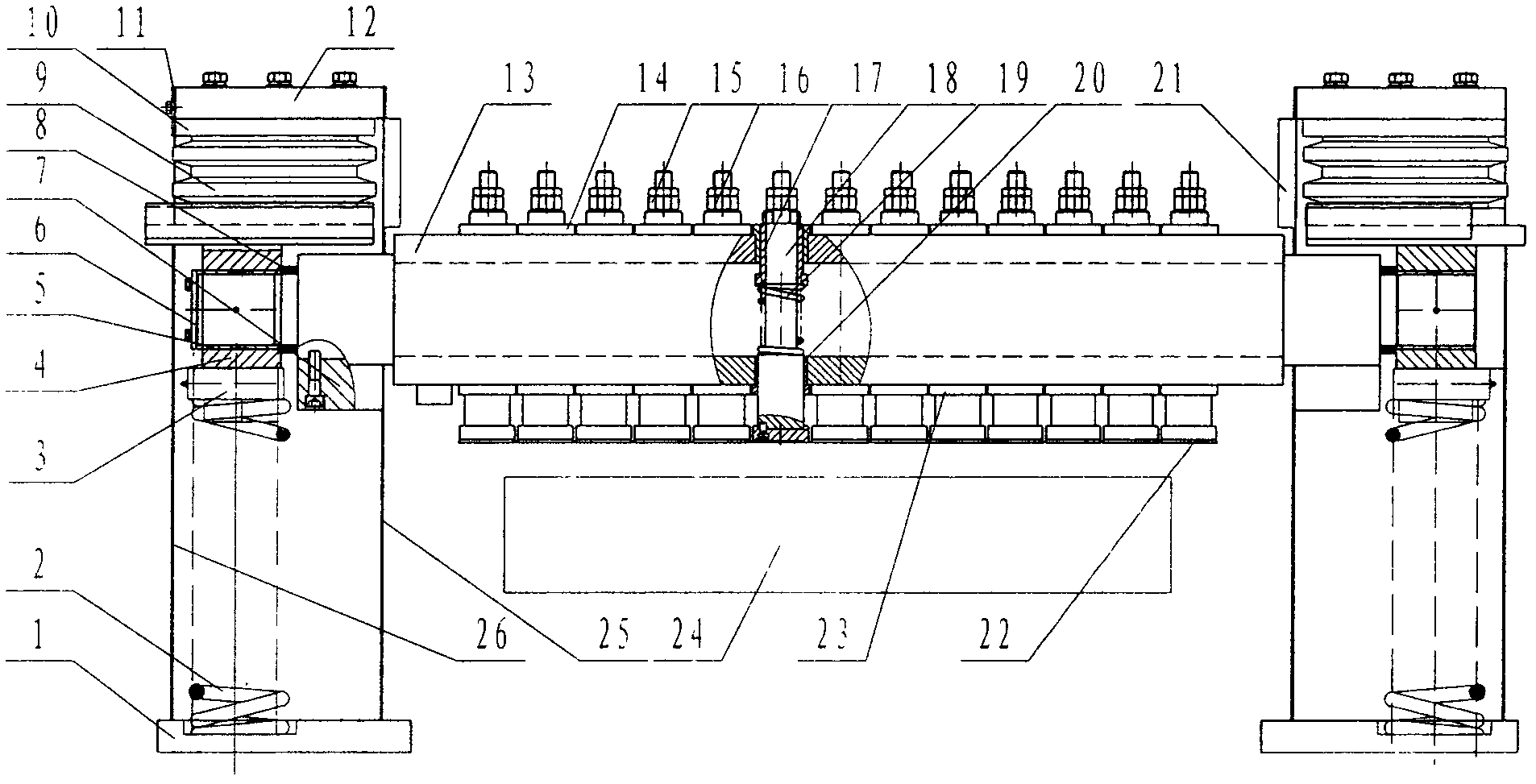

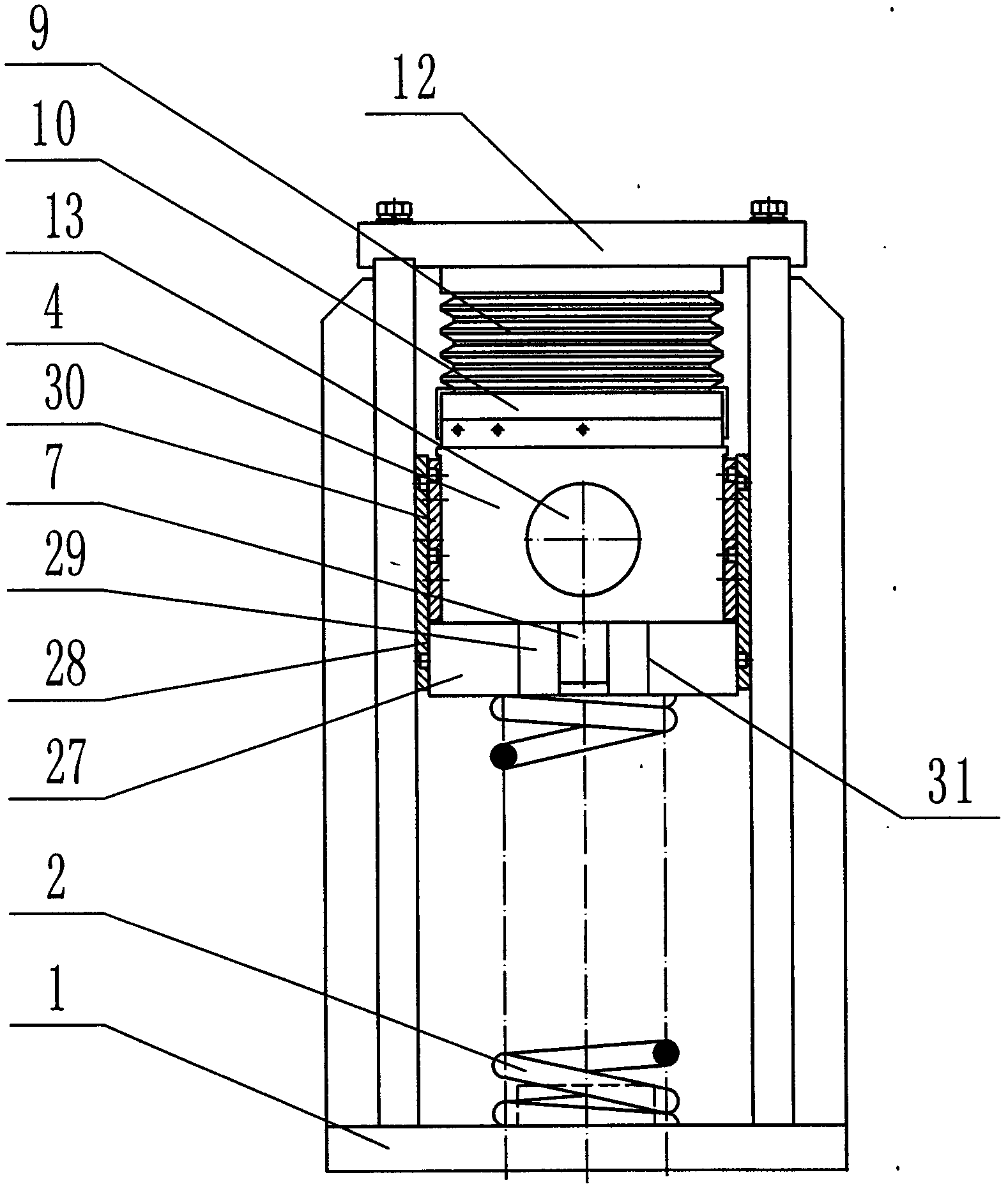

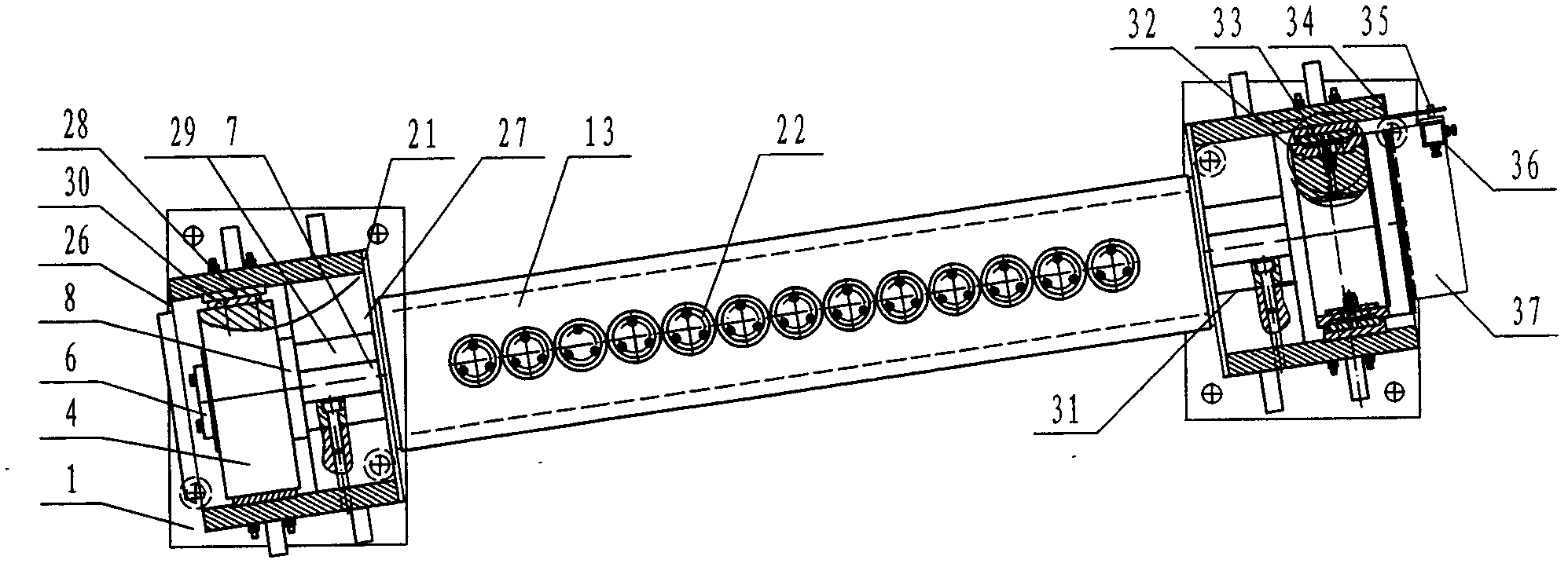

[0027] The deburring machine is mainly composed of a frame, a knife table, a knife table turning system, a lifting airbag, an electrical master control box, a control box next to the machine and a photoelectric detection system.

[0028] Frame: The frame is mainly composed of the top plate of the frame, the frame, the limit block and the stop seat, etc. The frame is used to withstand the impact force of the tool table and is the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com