Self-controlled heating welding electric circuit device

A circuit device and gas circuit technology, applied in the direction of circuits, auxiliary devices, electrical components, etc., can solve the problems of potential safety hazards, resource waste, long-time ignition, etc., and achieve a safe and reliable working environment, prevent burning waste, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

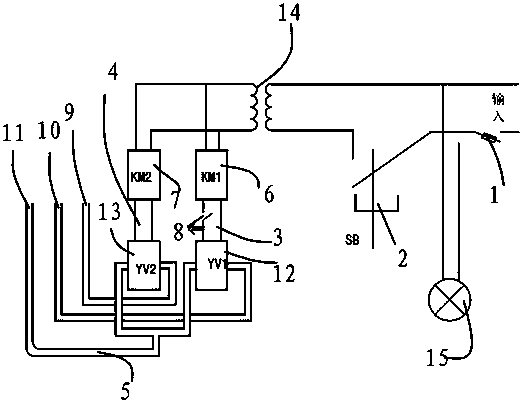

[0024] like figure 1 As shown, the electrical circuit device for self-controlled heating welding includes a voltage input port 1, a main power switch 2, a first gas circuit 3, a second gas circuit 4 and a third gas circuit 5, and the first gas circuit 3 includes the first gas circuit connected in sequence. A control electric contactor 6, the inlet of the first solenoid valve 12 and the liquefied gas inlet 10, the second gas circuit 4 includes the second control electric contactor 7, the inlet of the second solenoid valve 13 and the oxygen inlet 9 connected in sequence, the first The three gas circuit 5 includes the mixed gas outlet 11 formed after the outlet of the first solenoid valve 12 and the outlet of the second solenoid valve 13 merge. A step-down transformer 14 is set between them, and the 220V input from the input voltage port is transformed into a safe voltage of 24V. The electrical circuit setting of this device is through the joint action of two electric control co...

Embodiment 2

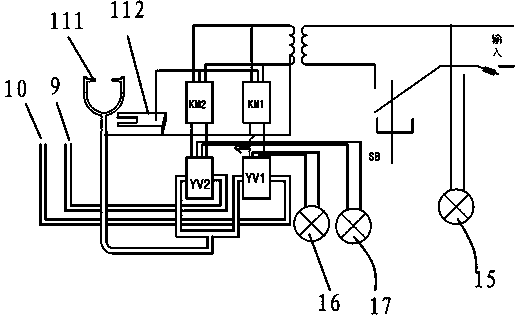

[0027] like figure 2 As shown, the electric circuit device of self-controlled heating welding is the same as that of Embodiment 1, the difference is that the mixed gas outlet 11 is provided with a U-shaped fire head gun 111, and the mixed gas outlet 11 is connected to the output area of the step-down transformer 14; the first control electrical contact The entrance of device 6 and the second control electrical contactor 7 is connected with draw-in groove 112, and draw-in groove 112 is provided with U-shaped notch, and fire head gun 111 is a three-way structure, and fire head gun 111 can be hung on the notch of draw-in groove 112. When the muzzle gun 111 is hung on the slot 112, that is, when the two are in contact with each other, the second gas path is short-circuited, and the oxygen is immediately disconnected. When short-circuited, the solenoid valve does not work, the fire is cut off, and the heating and welding can be controlled conveniently.

[0028] In order to avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com