A highly efficient and environmentally friendly coke oven dust removal and smoke guide equipment

A coke oven dust removal and environmental protection technology, applied in the coking field, can solve the problems of resource waste, environmental hazards, insufficient combustion of flue gas, etc., and achieve the effect of avoiding combustion waste, meeting environmental protection requirements, and meeting user needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

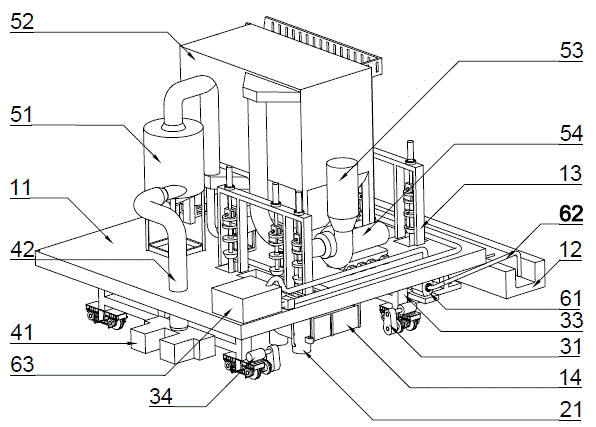

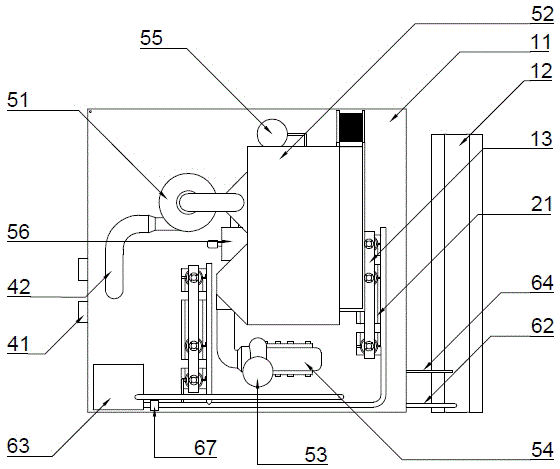

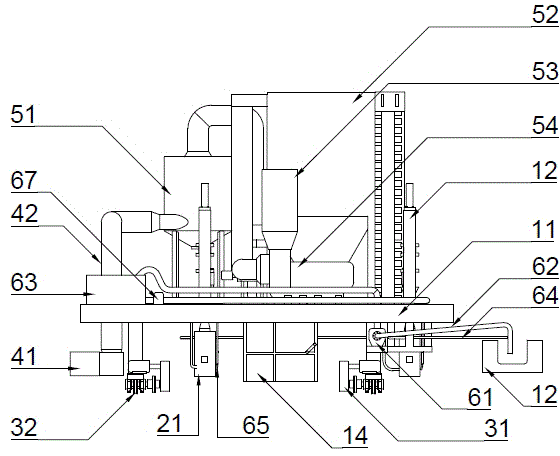

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as Figure 1-7 A high-efficiency and environment-friendly coke oven dust removal and smoke guide equipment shown mainly includes: steel structure platform 11, smoke guide device, walking device, machine side furnace door smoke guide device, dust removal device, water supply cooling device:

[0026] The steel structure mainly includes a steel structure platform 11, a water tank 12, a bracket 13, and a driver's cab 14. The steel structure platform 11 is used as the main body of the coke oven soot treatment equipment, and the water tank 12 is installed parallel to the roof rails on the coke oven soot treatment equipment. On the side of the equipment, the bracket 13 is welded above the steel structure platform 11, the cab 14 is hung below the steel structure platform 11, and is located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com