Preparation method of Fe-MCM-41 molecular sieve with high iron content

A technology of fe-mcm-41 and molecular sieve, which is applied in the field of preparation of MCM-41 molecular sieve, can solve the problem that the iron content needs to be improved, and achieve the effect of strong application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

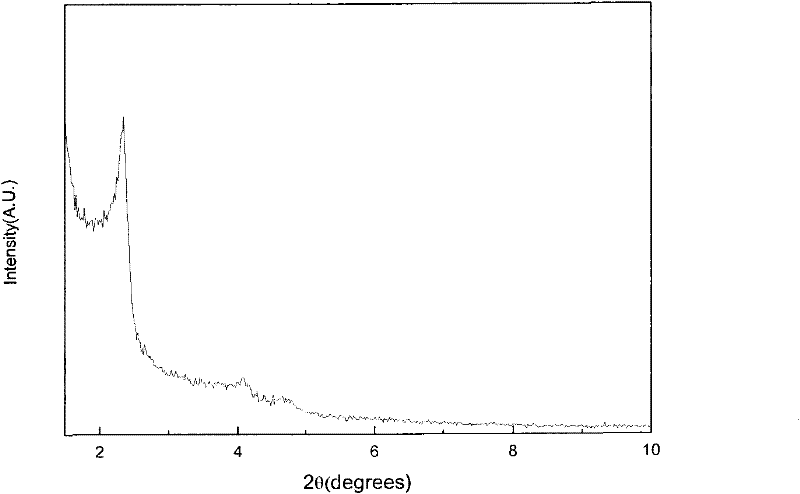

Embodiment 1

[0017] Dissolve a certain amount of ferric nitrate and sodium tartrate (TA) in deionized water and stir for 40 minutes at room temperature, add organic template agent cetyltrimethylammonium bromide (CTAB), stir for 60 minutes, add ethyl orthosilicate dropwise After stirring for 60 min, the pH value was adjusted to 9 with NaOH solution. After continuous stirring for 2 h, the obtained emulsion was transferred into a polytetrafluoroethylene-lined reaction tank, and statically crystallized at 110° C. for 96 h. The molar composition ratio of reactants is CTAB:SiO 2 =0.2, Fe(NO 3 ) 3 : SiO 2 =0.15,H 2 O: SiO 2 =100, TA:SiO 2 = 0.3. After crystallization of the product, cool to room temperature, filter with suction, wash until the pH of the filtrate is 7, dry at 80°C, heat up to 550°C at a rate of 1°C / min, and keep warm for 6 hours to obtain the finished product. XRF characterizes that the finished product contains 11.75wt% Fe, N 2 The specific surface area of the sample me...

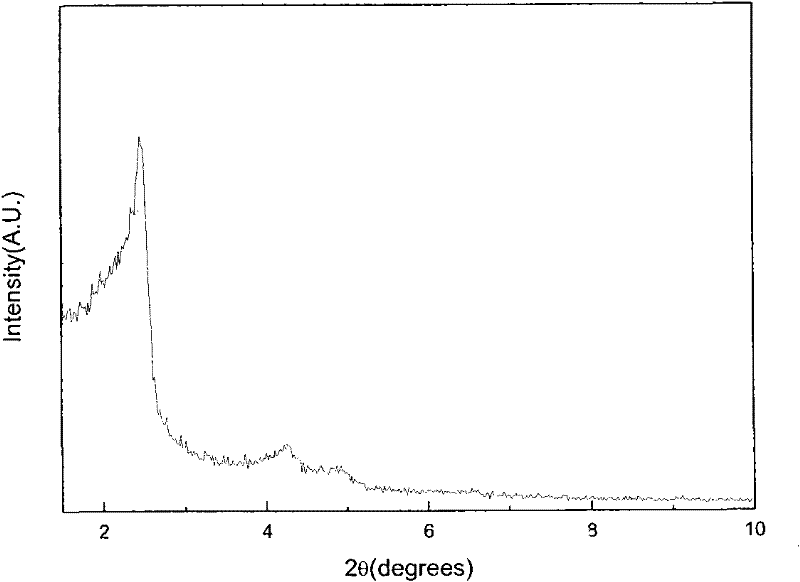

Embodiment 2

[0019] Dissolve a certain amount of ferric nitrate and sodium tartrate (TA) in deionized water and stir for 40 minutes at room temperature, add organic template agent cetyltrimethylammonium bromide (CTAB), stir for 60 minutes, add ethyl orthosilicate dropwise After stirring for 60 min, the pH value was adjusted to 9 with NaOH solution. After continuous stirring for 2 h, the obtained emulsion was transferred into a polytetrafluoroethylene-lined reaction tank, and statically crystallized at 110° C. for 96 h. The molar composition ratio of reactants is CTAB:SiO 2 =0.2, Fe(NO 3 ) 3 : SiO 2 =0.1,H 2 O: SiO 2 =100, TA:SiO 2 = 0.2. After crystallization of the product, cool to room temperature, filter with suction, wash until the pH of the filtrate is 7, dry at 80°C, heat up to 550°C at a rate of 1°C / min, and keep warm for 6 hours to obtain the finished product. XRF characterizes that the finished product contains 7.34wt% Fe, N 2 The specific surface area of the sample meas...

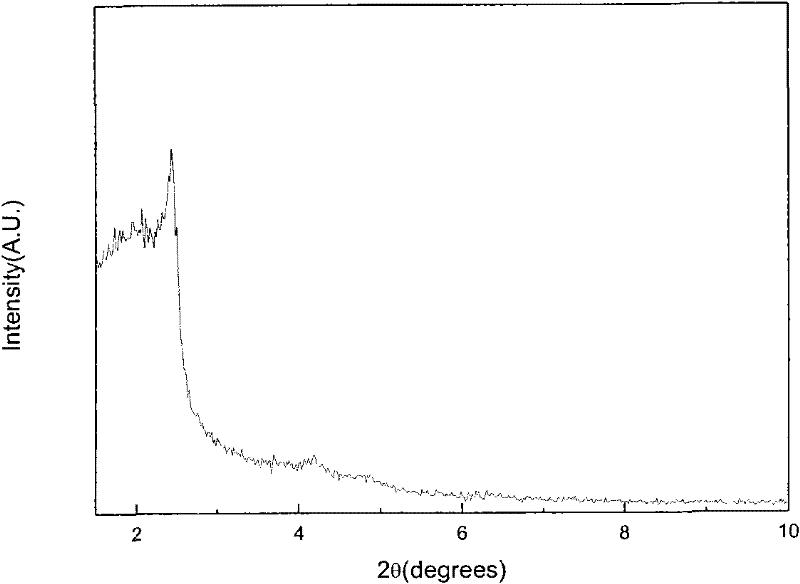

Embodiment 3

[0021] Dissolve a certain amount of ferric nitrate and sodium tartrate (TA) in deionized water and stir for 40 minutes at room temperature, add organic template agent cetyltrimethylammonium bromide (CTAB), stir for 50 minutes, add ethyl orthosilicate dropwise After stirring for 100 min, the pH value was adjusted to 9 with NaOH solution. After continuous stirring for 3 h, the resulting emulsion was transferred into a polytetrafluoroethylene-lined reaction tank and statically crystallized at 110° C. for 60 h. The molar composition ratio of reactants is CTAB:SiO 2 =0.2, Fe(NO 3 ) 3 : SiO 2 =0.15,H 2 O: SiO 2 =125, TA: SiO 2 = 0.3. After crystallization of the product, cool to room temperature, filter with suction, wash until the pH of the filtrate is 7, dry at 80°C, heat up to 550°C at a rate of 1°C / min, and keep warm for 6 hours to obtain the finished product. XRF characterizes that the finished product contains 11.26wt% Fe, N 2 The specific surface area of the sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com