Copper-bearing antibacterial titanium alloy and preparation method thereof

A technology of titanium alloy and pure titanium, which is applied in the field of antibacterial titanium alloy and its preparation, can solve the problems of poor long-term effect, easy decay or loss of antibacterial layer, etc., and achieve good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Embodiment 1: A copper-containing antibacterial titanium alloy in this embodiment is made by adding 1% to 30% copper in mass percentage to pure titanium or titanium alloy.

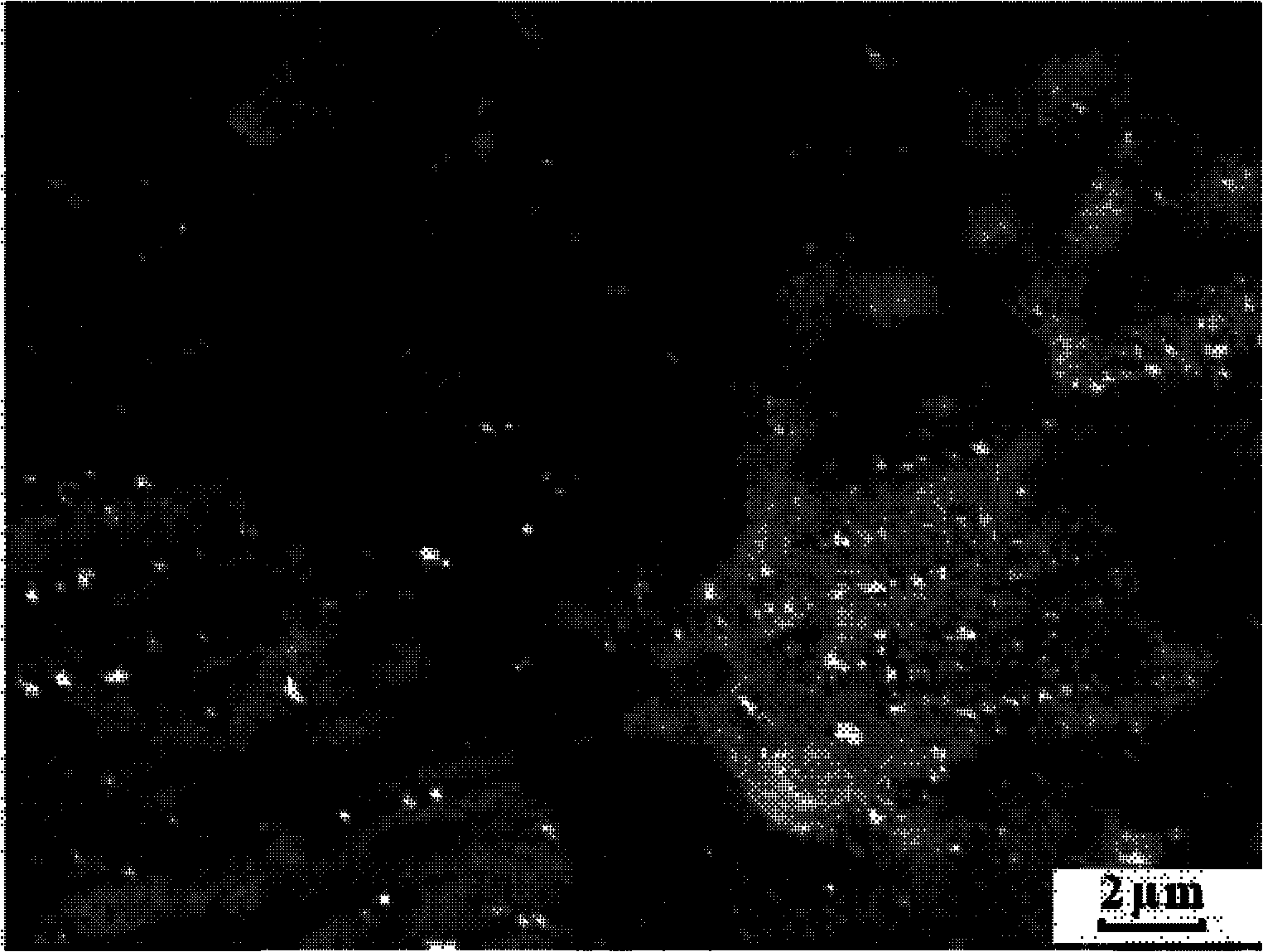

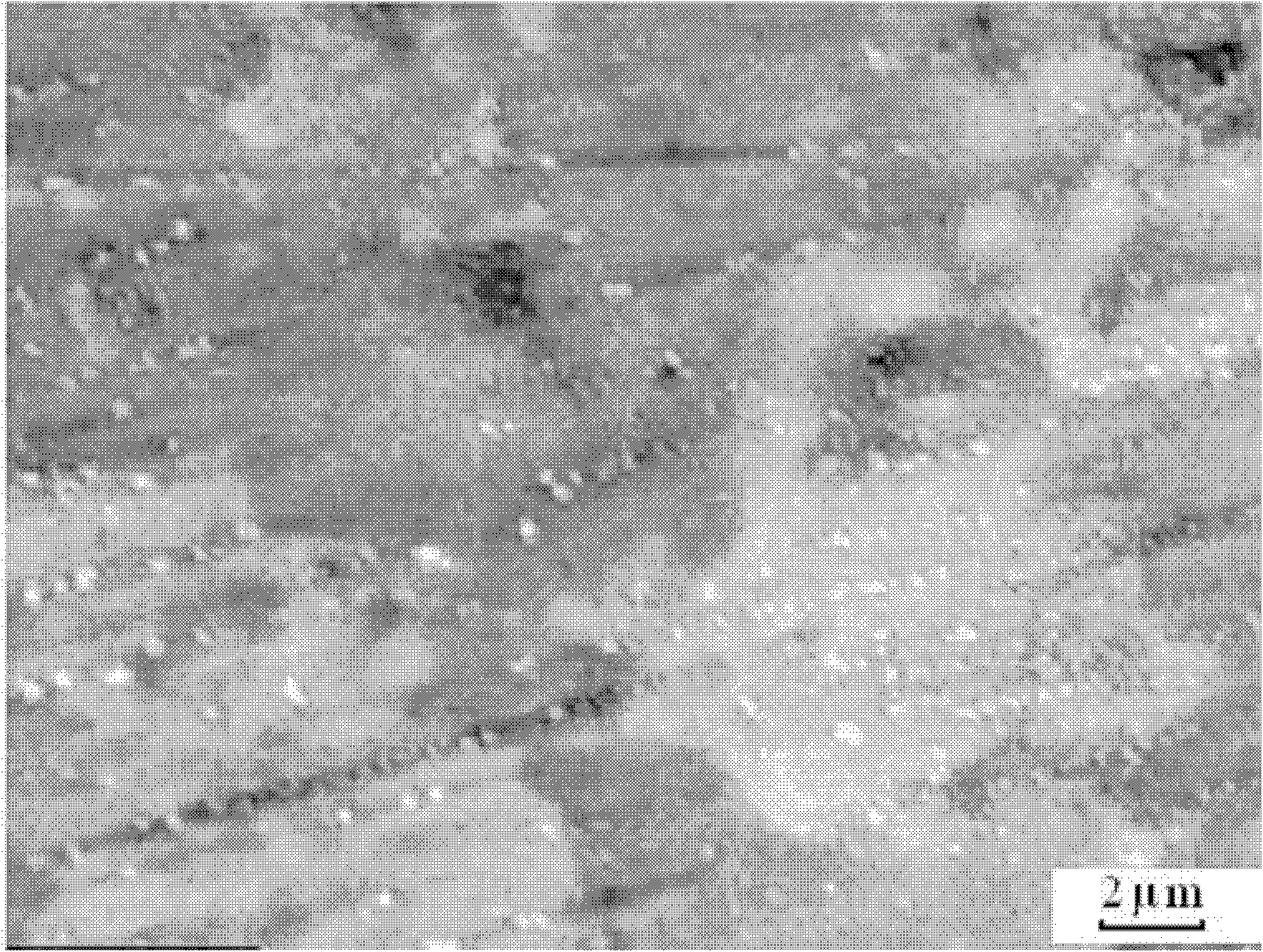

[0013] Pure titanium in this embodiment refers to titanium with a titanium content ≥ 99.9% (mass).

[0014] In the copper-containing antibacterial titanium alloy of this embodiment, copper element is added to pure titanium or titanium alloy to form an antibacterial phase in the titanium alloy. When the copper-containing antibacterial titanium alloy is in contact with bacterial liquid or other liquids, Cu ions will be dissolved, and the dissolved Cu ions have a bactericidal effect, thereby achieving a bactericidal and antibacterial effect. The copper-containing antibacterial titanium alloy of this embodiment is to make the whole titanium alloy have antibacterial properties through alloying treatment, that is, the integral antibacterial titanium alloy. It has good antibacterial properties even after ...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that the titanium alloy is an α-type titanium alloy, a β-type titanium alloy or an α+β-type titanium alloy; other aspects are the same as Embodiment 1.

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the titanium alloy is Ti-6Al-4V, Ti-6Al-7Nb, Ti-5Al-2.5Fe, Ti-12Mo-6Zr-2Fe, Ti-15Mo-5Zr-3Al, Ti-15Mo-3Nb-3O, Ti-15Zr-4Nb-2Ta-0.2Pd, Ti-15Zr-4Nb-2Ta-0.2Pd, Ti-13Nb-13Zr or Ti-Nb-Ta- Zr. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com