Method for preparing nitrogen-doped P-type zinc oxide film in one step by using nitrogen as doping source

A technology of zinc oxide film and nitrogen doping, which is applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of increasing film complexity and controllable parameters, and achieve the goal of reducing related temperature parameters control, good film quality and good resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

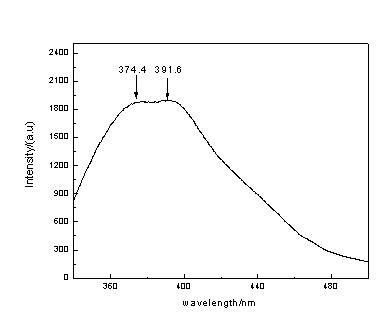

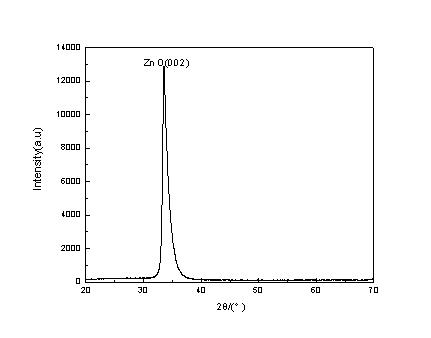

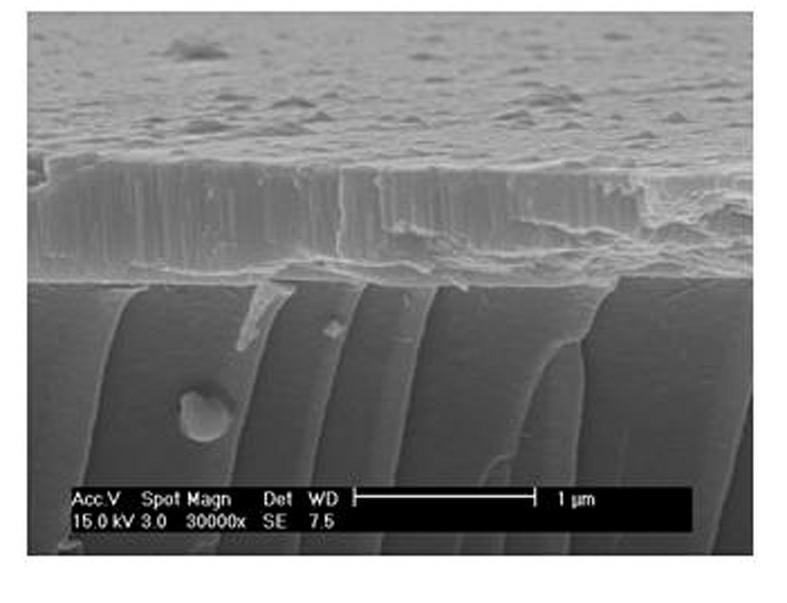

[0024] Example 1: Zinc oxide with a purity of 99.99% is used as the sputtering target, and glass is used as the substrate material. First, the substrate material is ultrasonically cleaned with acetone, alcohol, and deionized water according to conventional methods to remove surface grease. and dirt, and then dry it with hot air, and then put it into the magnetron sputtering chamber, when the vacuum degree in the sputtering chamber reaches 1.0*10 -4 At Pa, the sputtering gas argon is introduced to make it glow, and then the reaction gases oxygen and nitrogen are introduced, so that the ratio of the standard milliliters / minute (sccm) of argon, oxygen and nitrogen is 15:6: 9. At the same time, apply a bias voltage of -120V to the substrate to keep the working pressure at 0.6Pa, and the power is 120W. After sputtering for 40min, a nitrogen-doped zinc oxide film is directly obtained. Both the Hall effect and fluorescence spectra show that the film is P-type zinc oxide, and its resi...

Embodiment 2

[0025] Example 2: Zinc oxide with a purity of 99.99% is used as the sputtering target, and glass is used as the substrate material. First, the substrate material is ultrasonically cleaned with acetone, alcohol, and deionized water according to conventional methods to remove surface grease. and dirt, and then dry it with hot air, and then put it into the magnetron sputtering chamber, when the vacuum degree in the sputtering chamber reaches 1.0*10 -4 At Pa, the sputtering gas argon is introduced to make it glow, and then the reaction gases oxygen and nitrogen are introduced, so that the ratio of the standard milliliters / minute (sccm) of argon, oxygen and nitrogen is 14:7: 8. At the same time, apply a bias voltage of -80V to the substrate to keep the working pressure at 0.2Pa, and the power is 200W. After sputtering for 30min, a nitrogen-doped P-type zinc oxide film is directly obtained. Both Hall effect and fluorescence spectra show that the film is P-type zinc oxide, and its re...

Embodiment 3

[0026] Example 3: Zinc oxide with a purity of 99.99% is used as the sputtering target, and glass is used as the substrate material. First, the substrate material is ultrasonically cleaned with acetone, alcohol, and deionized water according to conventional methods to remove surface grease. and dirt, and then dry it with hot air, and then put it into the magnetron sputtering chamber, when the vacuum degree in the sputtering chamber reaches 1.0*10 -4 At Pa, the sputtering gas argon is introduced to make it glow, and then the reaction gases oxygen and nitrogen are introduced, so that the standard ml / min (sccm) ratio of argon, oxygen and nitrogen is 16:5: 10. At the same time, apply a bias voltage of -200V to the substrate to keep the working pressure at 1.0Pa, and the power is 80W. After sputtering for 60 minutes, a nitrogen-doped zinc oxide film is directly obtained. Both the Hall effect and fluorescence spectra show that the film is P-type zinc oxide, and its resistivity is 6.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap