Neutral rust removing detergent

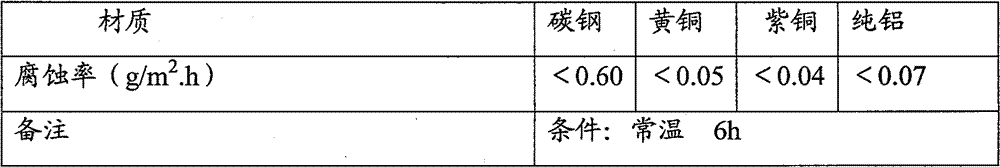

A rust-removing cleaning agent and cleaning agent technology, applied in the field of cleaning agents, can solve the problems of high volatility of cleaning liquid, unfavorable long-term storage, temperature limitation of dissolution, etc., achieving good rust-removing effect, not easy to decompose and deteriorate, cleaning time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Neutral derusting cleaning agent preparation method of the present invention, it comprises the steps:

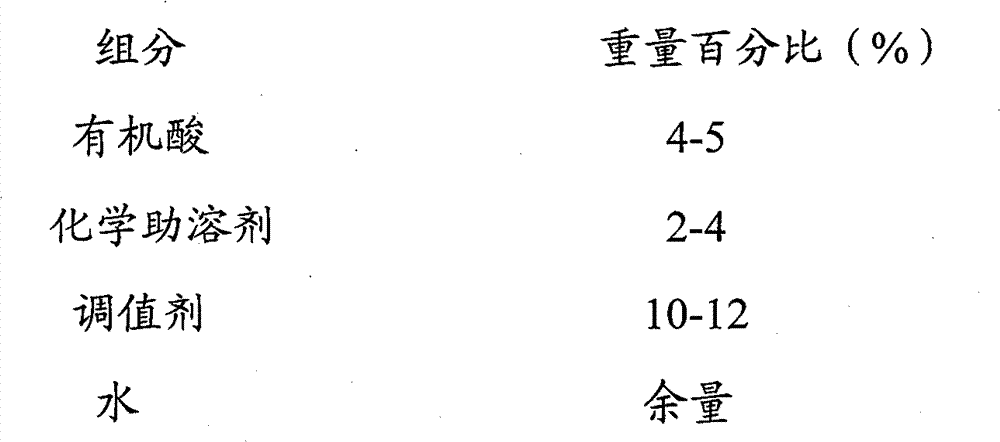

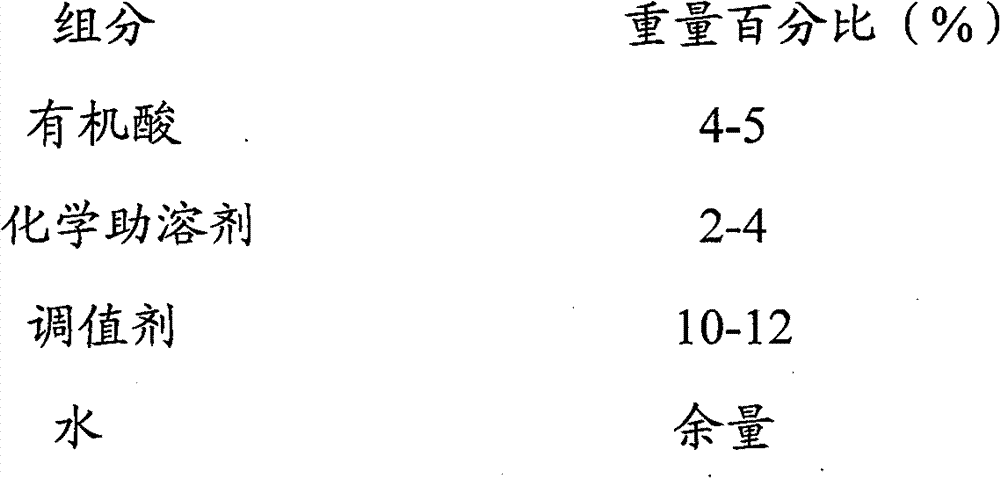

[0044] a. The weight percentage of each component given by the formula; specifically (weight percentage) 4% oxalic acid, 2% NH 2 CONH 2 ;

[0045] b. Dissolving the organic acid in water;

[0046] c. Directly stir or slightly heat to dissolve it, then add co-solvent, and then add value-adjusting agent to adjust the solution to neutral to complete the preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com