Cylinder bore and method for producing the same

A manufacturing method and cylinder bore technology, applied to cylinders, cylinder heads, engine components, etc., can solve problems such as deformation and product quality degradation, and achieve the effects of preventing cracks, achieving product quality, and achieving durability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

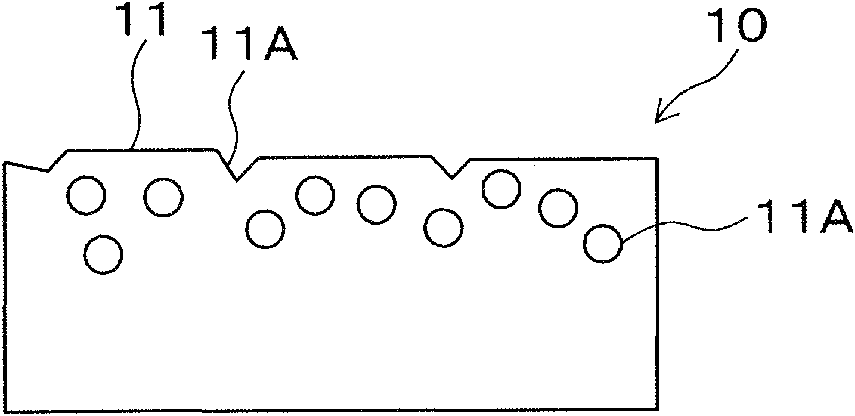

[0038] 1. Embodiment 1 (evaluation of surface roughness control)

[0039] In Example 1, evaluation of surface roughness control was performed. In the boring process, a plurality of cylinder bores with approximately the same surface roughness were obtained, and in the plastic working of the cylinder bores, the amount of polishing was changed, and the surface roughness Ra (μm) of the cylinder bores before and after plastic working was studied. The relationship between the amount of polishing. The result is in image 3 shown in .

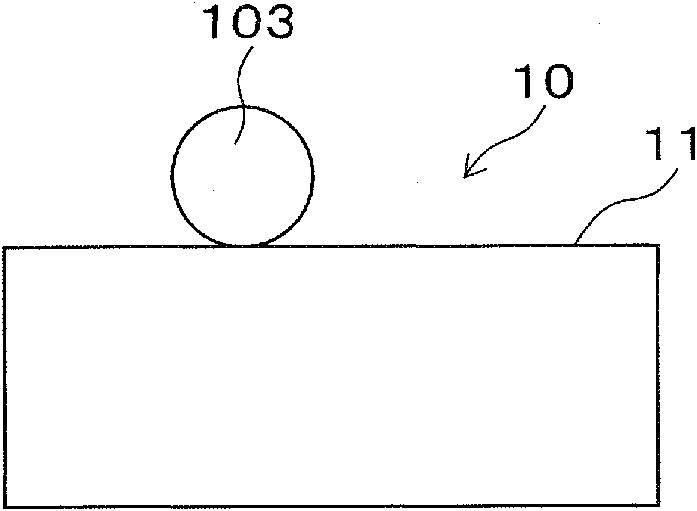

[0040] It should be noted that, in Example 1, only one cylinder bore is subjected to plastic working for each cylinder block. image 3 In , the polishing amount (μm) is defined as the difference between the diameter of the cylinder bore before plastic working and the tool diameter of the polishing tool 100 (the length from the center of the mandrel 101 to the outermost peripheral surface of the roller 103 ). In the evaluation of surface roughness...

Embodiment 2

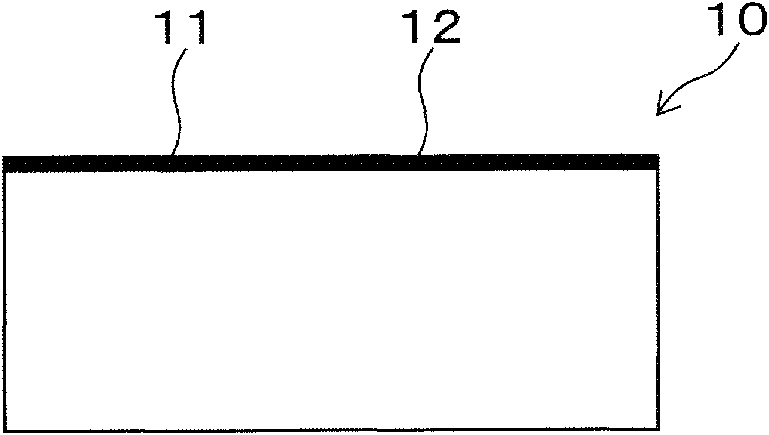

[0044] In Example 2, evaluation of cylindricity was performed. In the boring process, a cylinder block having a cylinder bore with approximately the same surface roughness was obtained. In the plastic working of the cylinder bore, the amount of polishing was changed to obtain the cylindricity (μm) and The relationship between the amount of polishing (μm) and the evaluation of cylindricity was carried out. It should be noted that the polishing amount is defined as the maximum value of the difference between the bore diameter of the cylinder bore before plastic working and the bore diameter of the cylinder bore after plastic working. like Figure 5 As shown, the cylindricity is defined as the difference between the maximum value R1 and the minimum value R2 of the bore diameter of the cylinder bore after plastic working.

[0045] Specifically, the cylindricity was evaluated for the following forms: the form for which only one cylinder bore was plastically worked for each cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plastic elongation ratio | aaaaa | aaaaa |

| plastic elongation ratio | aaaaa | aaaaa |

| plastic elongation ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com