Evaporator unit

An evaporator and ejector technology, applied in the direction of evaporator/condenser, compressor with multiple evaporators, indirect heat exchanger, etc., can solve the problem that the temperature distribution cannot be fully suppressed and the compressor cycle efficiency cannot be fully , hinder the miniaturization of the evaporator unit, etc., to achieve the effect of increasing the cross-sectional area, improving the circulation efficiency, and suppressing the increase of the pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

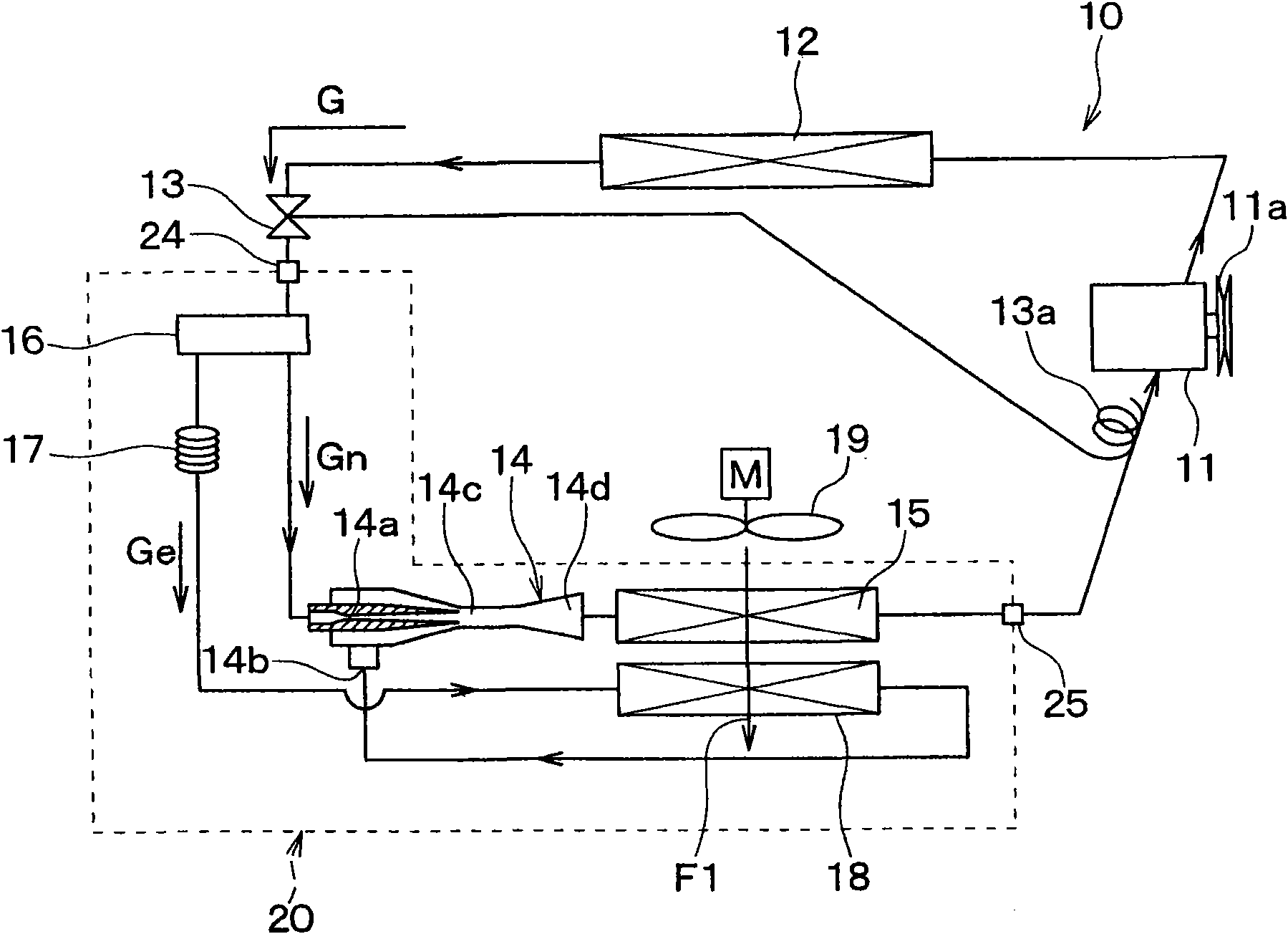

[0077] Hereinafter, a first embodiment of the present invention will be described. figure 1 An example in which the ejector refrigeration cycle 10 of the first embodiment is applied to a refrigeration cycle apparatus for a vehicle is shown.

[0078] existfigure 1 In the illustrated ejector refrigeration cycle 10 , a compressor 11 sucking and compressing refrigerant is driven and rotated by an unillustrated vehicle running engine via an electromagnetic clutch 11 a , a belt, and the like.

[0079] As the compressor 11, a variable capacity compressor capable of adjusting the refrigerant discharge capability according to a change in the discharge container may be used, or the refrigerant may be adjusted by changing the operating rate of the compressor by engaging or disengaging the electromagnetic clutch 11a. Any of the fixed-capacity compressors with discharge capacity. In addition, when an electric compressor is used as the compressor 11, the refrigerant discharge capability ca...

no. 2 approach

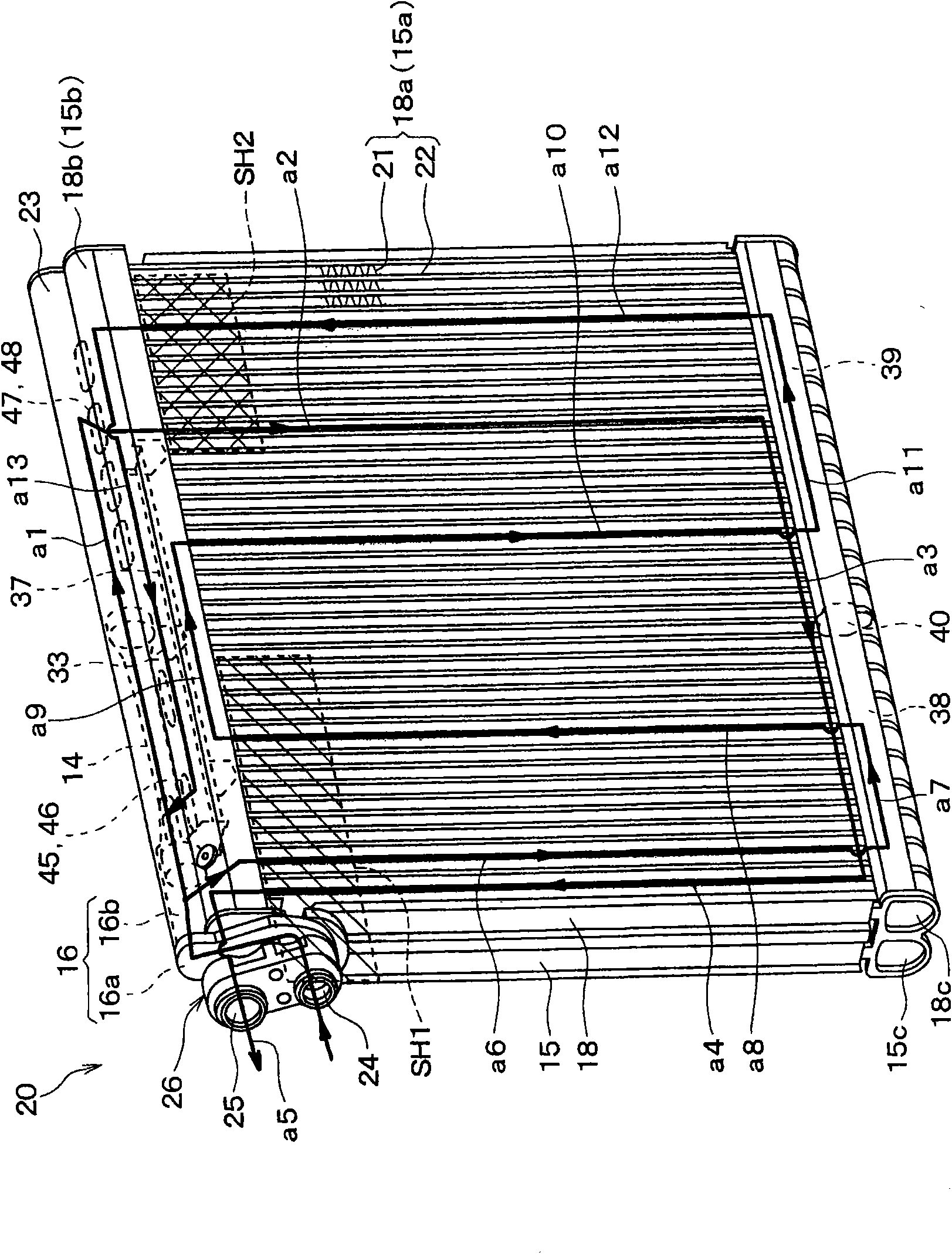

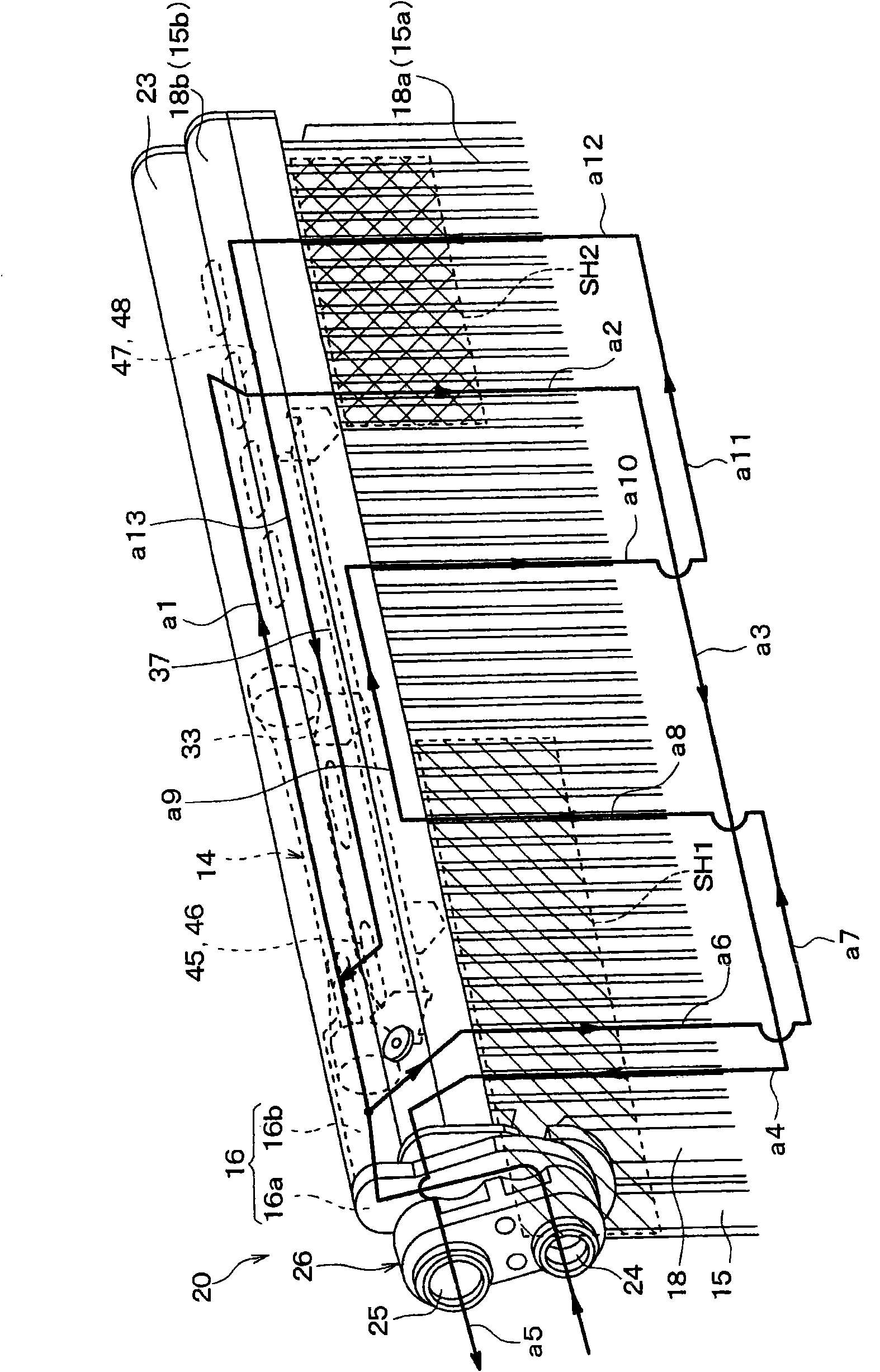

[0229] Figure 19A represents the integrated unit 120 of the second embodiment, Figure 19B express Figure 19A The connector 26. In this second embodiment, if Figure 19A As shown, the first evaporator 15 and the second evaporator 18 form a so-called laminated heat exchanger. That is, the first evaporator 15 and the second evaporator 18 have a tube plate (tube plate) 60 in which the tube 21 is formed by joining a pair of plates, and the first evaporator 15 and the second evaporator 18 have It is constructed by laminating a plurality of tube sheets 60 .

[0230] Specifically, a plurality of flat tubes 21 are formed by stacking aluminum plates that have been press-formed into a predetermined shape and then joined by brazing, and formed at both ends in the longitudinal direction of the tube 11 There are box parts 15b, 15c, 18b, 18c.

[0231] The tube sheet 60 is appropriately formed in a shape for constituting the refrigerant flow paths a1 to a13 similar to those in the fi...

no. 3 approach

[0234] In the above-mentioned first and second embodiments, the evaporator unit 20 used in the ejector refrigeration cycle 10 was described, but in this third embodiment, the evaporator unit 20 used in the expansion valve cycle 100 that does not include the ejector 14 is described. Evaporator unit 120 .

[0235] Such as Figure 20 As shown, in the expansion valve cycle 100 , a liquid receiver 12 a is provided on the outlet side of the radiator 12 . The liquid receiver 12a is a vertically long box-shaped member, and constitutes a gas-liquid separator that separates the gas-liquid of the refrigerant and stores the excess liquid refrigerant in the cycle. The liquid refrigerant is guided from the lower side of the inside of the tank shape to the outlet of the liquid receiver 12a. In addition, the liquid receiver 12a is integrally provided with the radiator 12 in this example.

[0236] In addition, as the radiator 12, a well-known structure having a heat exchange part for conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com