Local positioning cleaning method of wafer surface

A positioning cleaning and wafer technology, applied in cleaning methods and utensils, liquid cleaning methods, chemical instruments and methods, etc., can solve problems such as wafer surface positioning and cleaning, and achieve the effect of precise cleaning methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

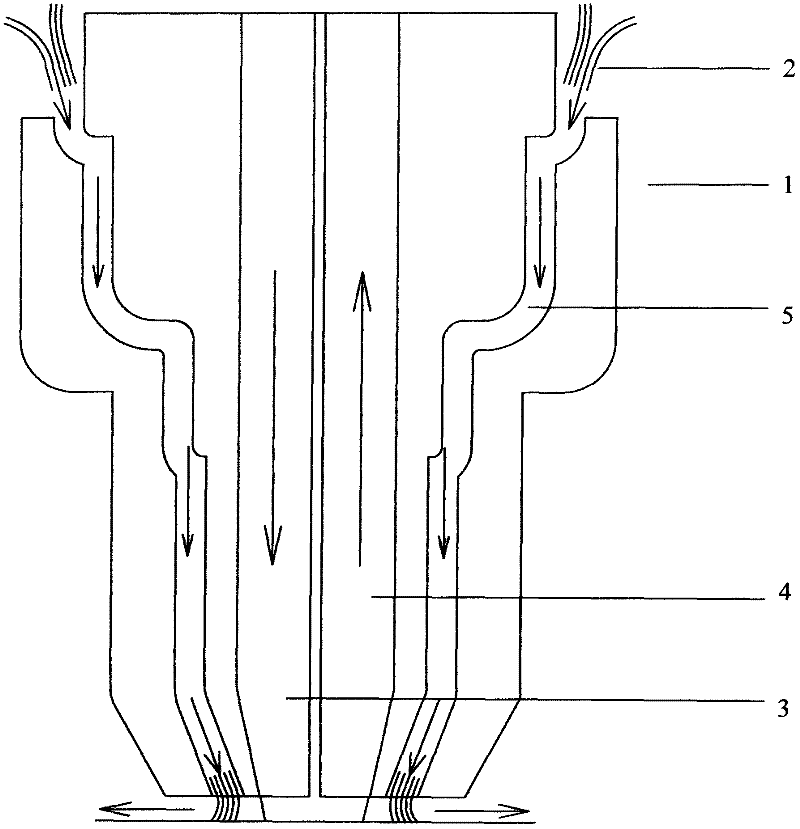

[0017] The present invention specifically adopts the following method to carry out local positioning and cleaning on the surface of the semiconductor wafer:

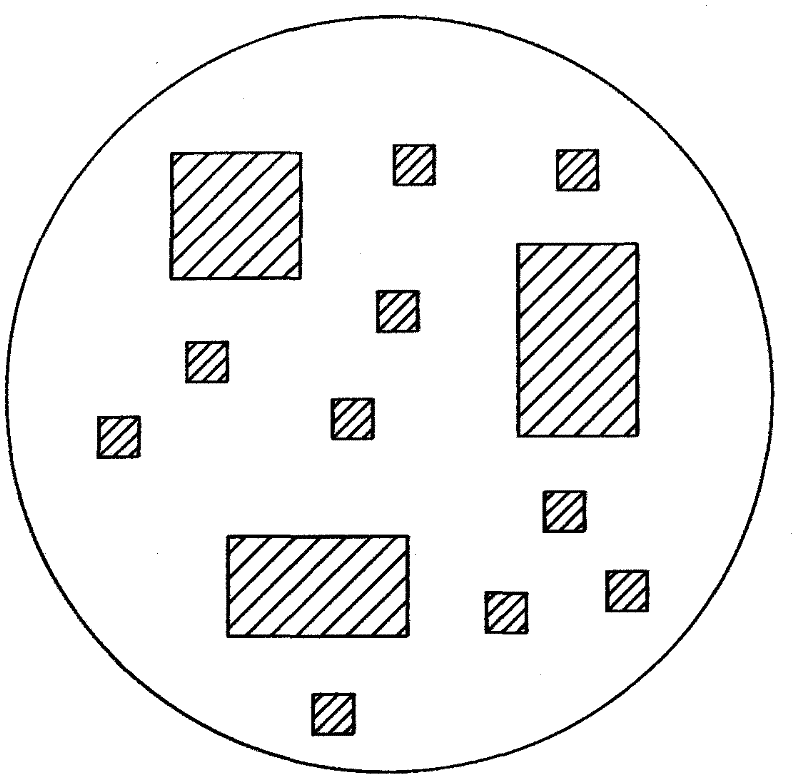

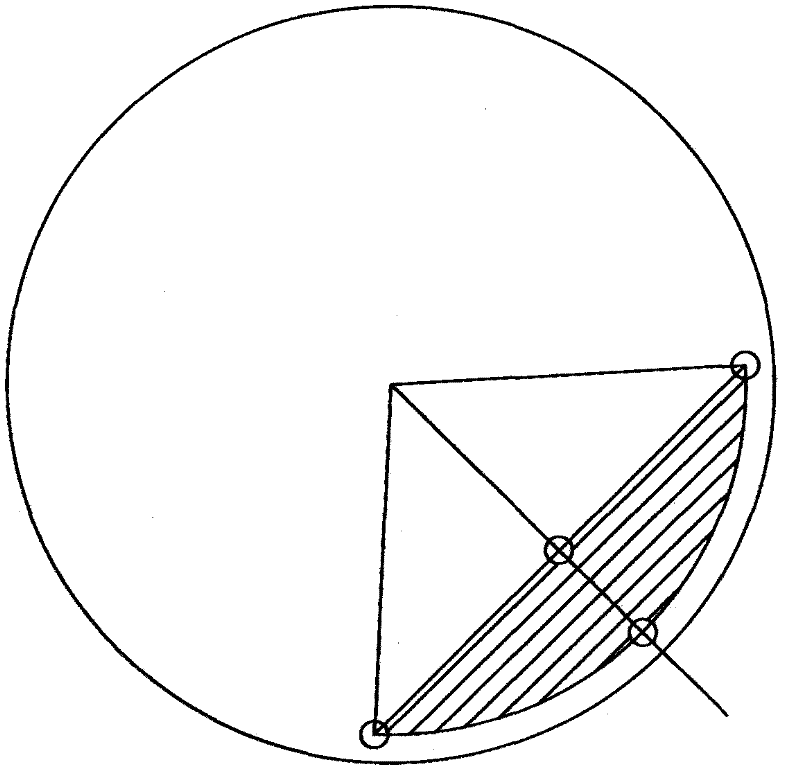

[0018] figure 1 and figure 2 A positioning method for wafer cleaning is shown. Before cleaning, the surface of the wafer is tested to determine the distribution area of pollutants, and then the test results are stored in the computer system; the contaminated wafer to be cleaned is selected, and the wafer is transported to the automatic cleaning device, and in the subsequent cleaning process The data of the contaminated area of the wafer is read out, and the wafer is positioned and cleaned. Pollutants can be tested using conventional techniques such as electrometry. Pollutants include metal pollutants and non-metal ion pollutants, among which metal pollutants include: Li, Be, Na, Mg, Al, K, V, Mn, Fe, Co, Ni, Cu, Zn, Ga, Sr, Y , Ag, Cd, Ba, Pb, Bi, Ce; non-metallic ion pollutants include: F - , Cl - , NO 3 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com