Single-edge magnetic levitation rotating device adopting double-coil rotating part

A technology of rotating parts and rotating devices, applied in the field of magnetic levitation, can solve problems such as complex structure and adjustment, falling, difficult two-way automatic rotation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

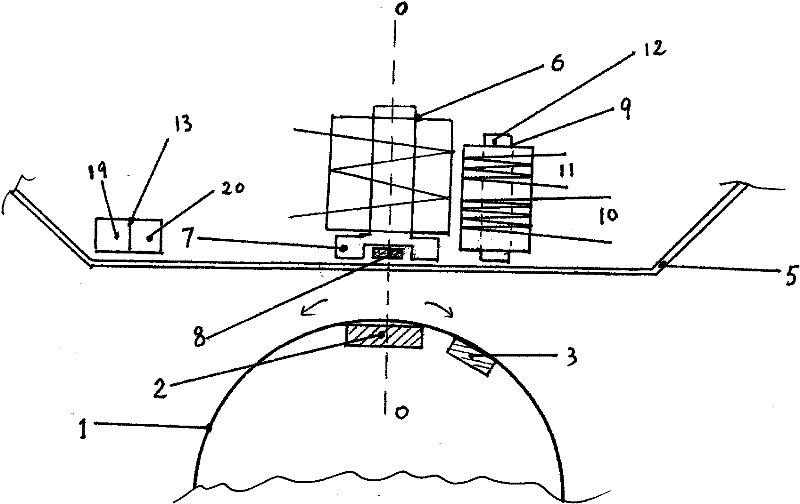

[0023] Embodiment 1: see below floating structure: figure 1

[0024] The centerline 0 of the upper part of the floating magnetic levitation rotor 1 is equipped with a flat magnetic levitation permanent magnet 2, and a permanent magnet 3 for rotation is installed next to it 2, in the box 5 above the magnetic levitation rotor 1 An electromagnet 6 is installed at the center line 0 of the center line, and the opening end of the iron core 7 of its 6 is facing downward, and a Hall element 8 is mounted on the opening end of the iron core 7, and a double wire is installed next to the electromagnet 6. Circle 9, it 9 is by two coils (10,11) of induction coil 10 and electromagnetic coil 11 as rotation sensor and is sheathed on the same ferromagnetic core 12 side by side, circuit board 13 is also housed in box body 5, The double coil 9 and the permanent magnet 3 are within the effective magnetic range of each other; the magnetic levitation rotating body 1 performs magnetic levitation and...

Embodiment 2

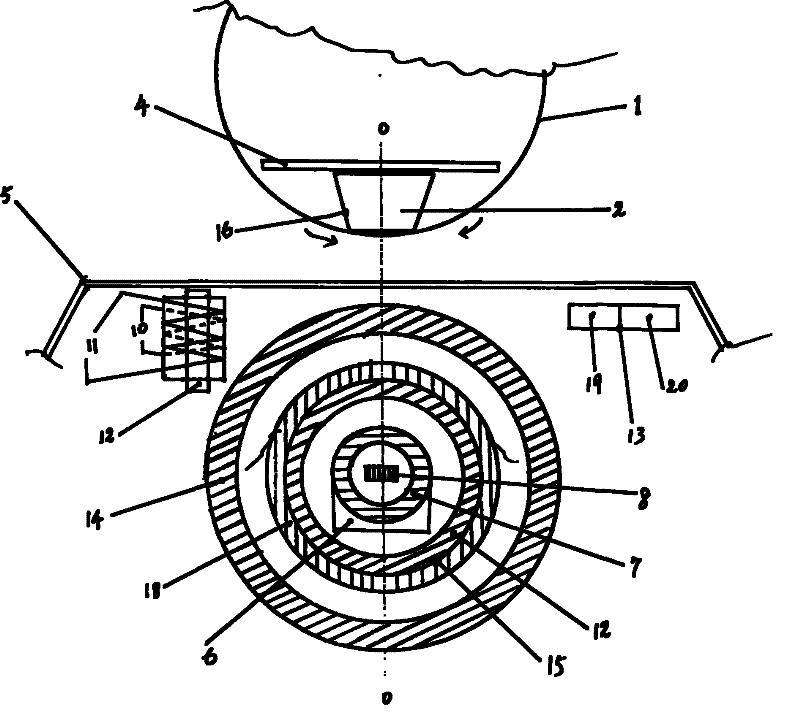

[0025] Embodiment 2: One of the floating structure sees: figure 2

[0026] At the center line 0 of the bottom of the maglev rotating body 1, a flat inverted conical magnetic levitating permanent magnet 2 is installed, and a magnetic guide 4 is mounted on its upper surface, and the box 5 below the maglev rotating body 1 Inside, hollow magnetic ring 14, electromagnet 6, double coil 9, circuit board 13, electromagnetic ring 15 are housed, and this electromagnetic ring 15 is made up of annular ferromagnetic core 12 and coil bag 18; Hollow The magnetic disk 14 is coaxial on the centerline 0 and has longitudinal magnetism. The upward magnetism of the hollow place of the magnetic ring 14 is the same magnetic field as that of the downward magnetic pole surface of the magnetic levitation permanent magnet 2. Then, the magnetic levitation The lower part of the rotating body 1 is floated in the air by the upward lifting force from the middle part of the magnetic ring 14 below, which is ...

Embodiment 3

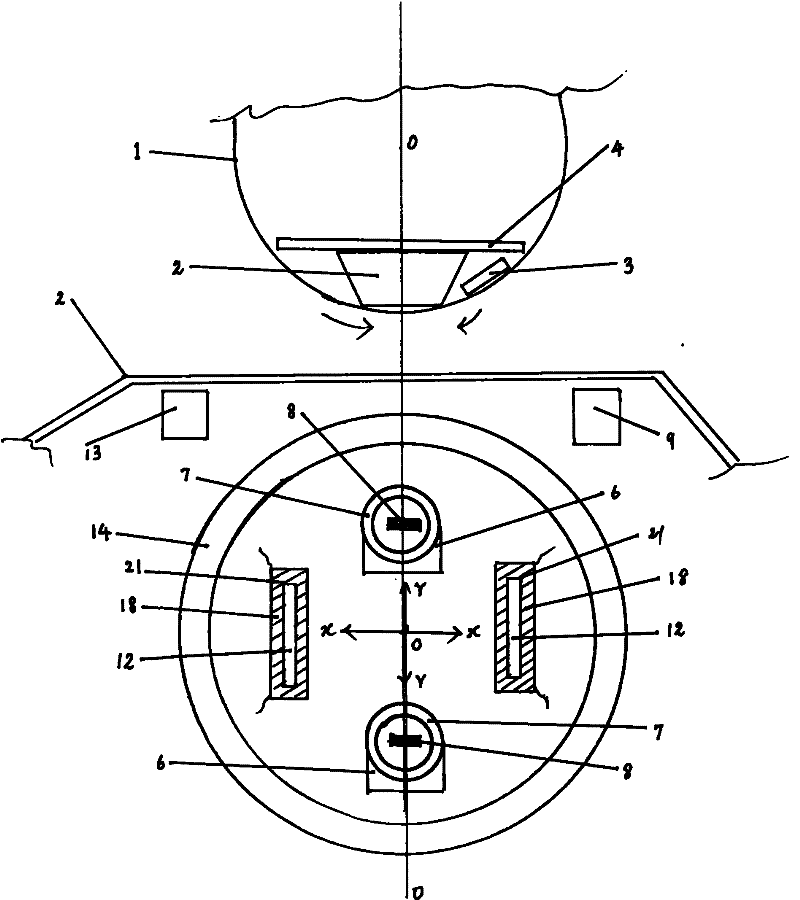

[0027] Embodiment 3: Another structure of floating type sees: image 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com