Heat-insulating and waterproof system of planted roof and construction method thereof

A construction method and technology of drainage system, applied in the direction of roof drainage, roof covering, building roof, etc., can solve the problems of being vulnerable to natural environment and man-made damage, unable to use roof rainwater, shortening service life, etc., to avoid The effect of leakage of internal structure, reduction of air pollution, and improvement of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

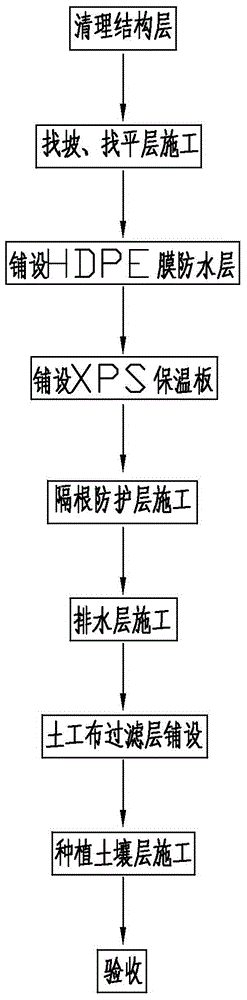

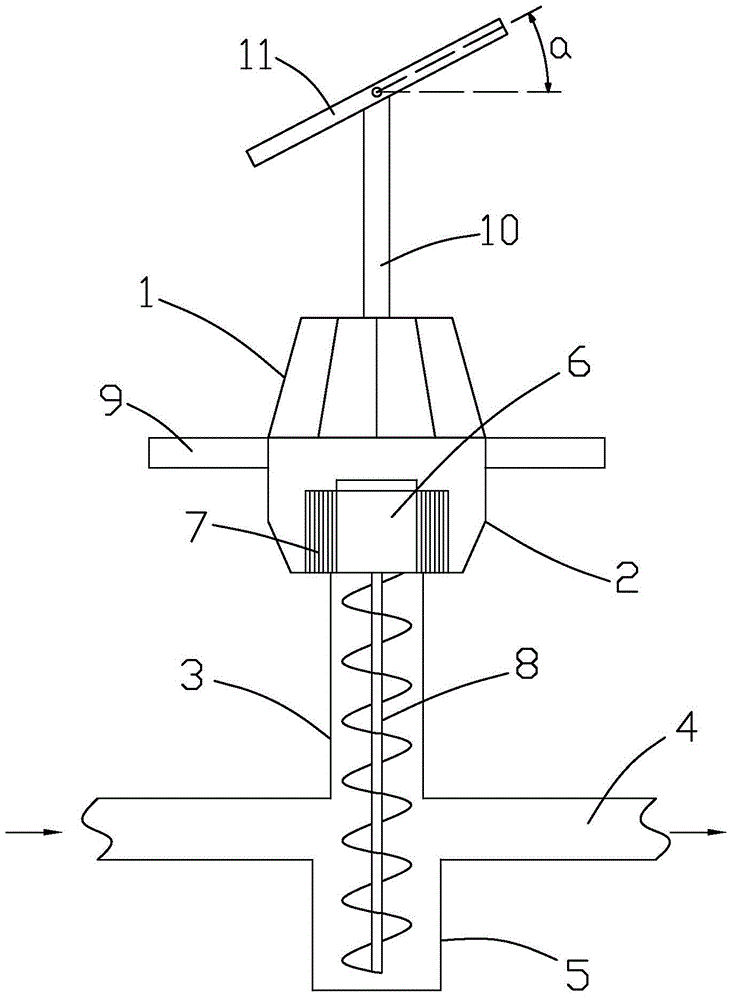

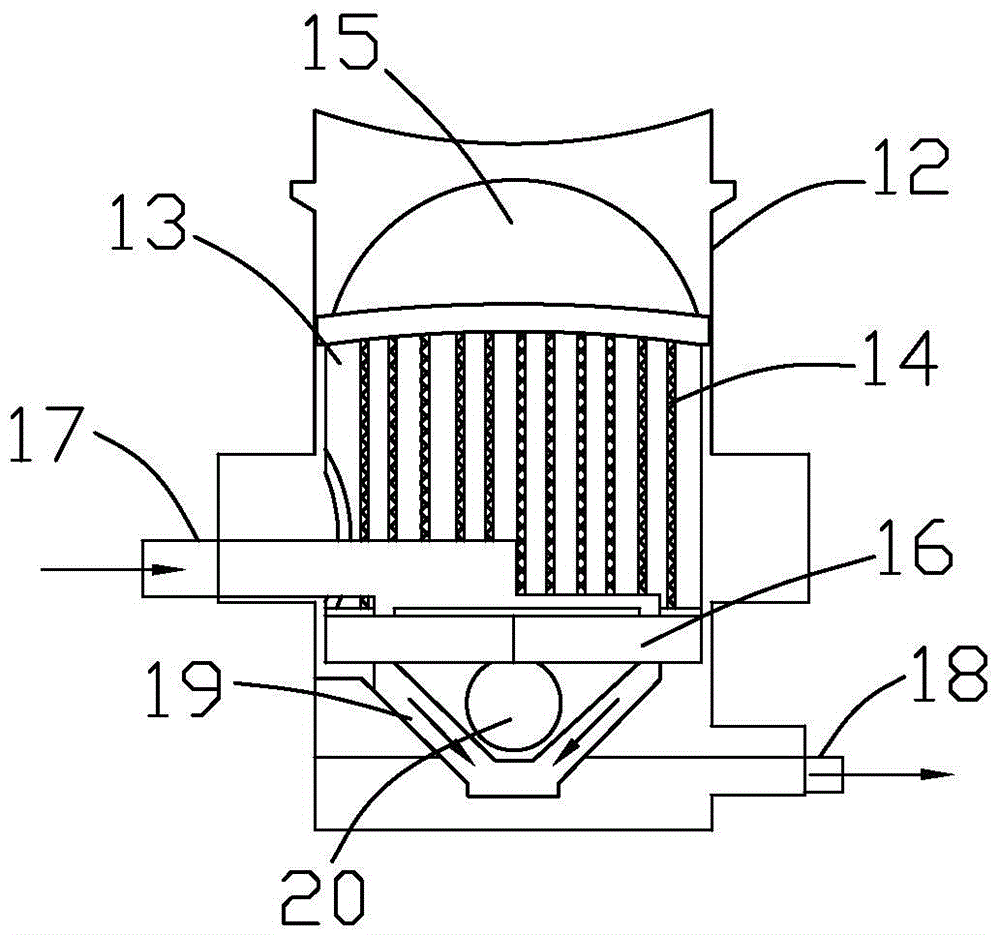

[0041] The technical principle of a planted roof thermal insulation and waterproof system and its construction method of the present invention is to filter the roof structure layer, slope layer, leveling layer, waterproof layer, XPS board insulation layer, root protection layer, drainage layer, and geotextile Layers and planting soil layers and other layers of construction, as well as water supply, storage, drainage and drainage systems, form a vegetation-type roof that is heat-insulating, impermeable, environmentally friendly and energy-saving.

[0042] The main construction machines and tools are shown in Table 1:

[0043] Machine name

Specification

purpose

High pressure hair dryer

400W

clean up grassroots

Hand-held roller

Φ40*50mm

Rolled Coil

scissors, strong paper knife

ordinary

Cut coils, insulation boards

small, ordinary

Grassroots treatment

[0044] long handle r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com