Profiling top-cutting machine for cotton top

A topping machine and cotton technology, which is applied in the direction of agricultural machinery and tools, cutting tools, cutting equipment, etc., can solve the problems of high labor intensity, low operation efficiency, and large limitations of ground profiling, so as to achieve good profiling effect, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

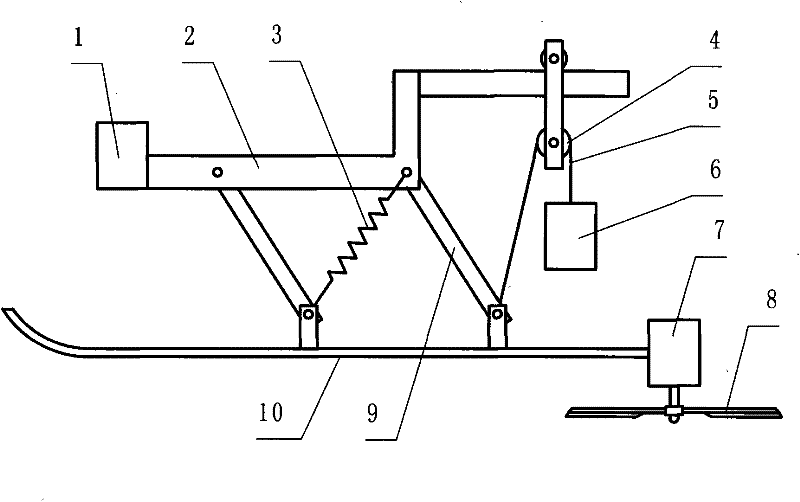

Embodiment 1

[0018] refer to figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, comprising a frame 1, a power mechanism, a transmission mechanism and a topping knife 8, a suspension frame 2 is arranged on the frame 1, and a suspension type profiling mechanism is suspended under the suspension frame 2, The suspension-type profiling mechanism includes a telescopic frame 9 and a sliding shoe plate. The projecting knife is arranged on the sliding shoe plate. 2 and the sliding shoe plate 10 are hinged to form a parallelogram four-bar linkage mechanism. The telescopic frame is provided with a spring 3, and the spring 3 is obliquely pulled on the two parallel bars and the suspension frame 2 and the sliding shoe plate 10 are hinged to form a parallelogram four-bar linkage. Between the two opposite obtuse angles of the mechanism, a balance mechanism is provided between the sliding shoe 10 and the suspension frame 9. The balance mechanism includes a pulley mechani...

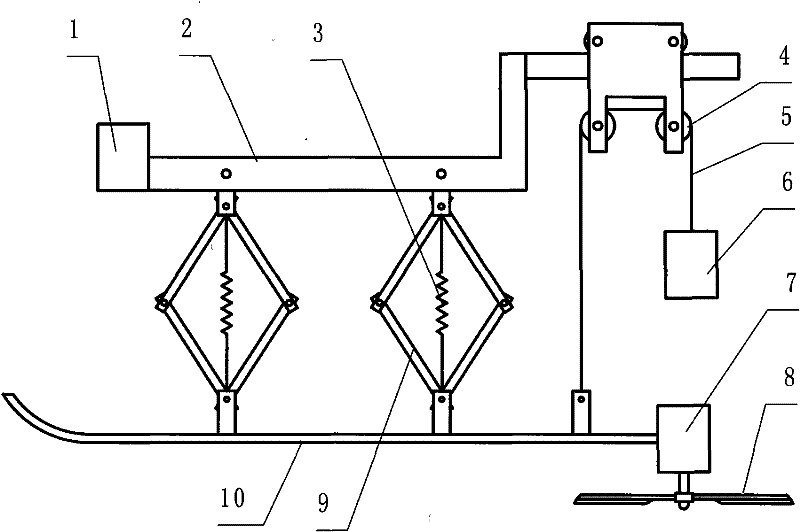

Embodiment 2

[0020] refer to figure 2 , is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the telescopic frame 9 is two parallelogram-shaped four-bar linkages, and the parallelogram-shaped four-bar linkages The upper and lower connection points of the mechanism are respectively connected with the suspension frame 2 and the sliding shoe plate 10, the spring 3 is arranged between the upper and lower connection points of the parallelogram four-bar linkage mechanism, and the pulley mechanism is provided with two horizontal pulleys 4, so that Can not interfere with each other between the counterweight 6 and the stay cord 5, and there are two rollers on the upper part of the pulley mechanism to ensure the stability of the pulley mechanism.

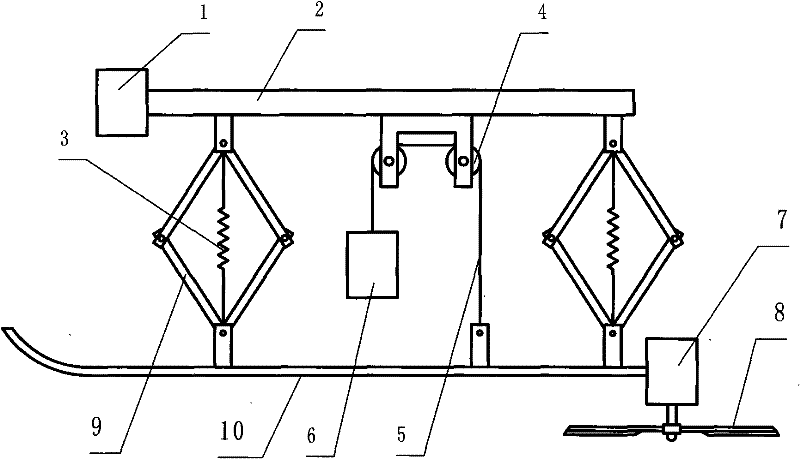

Embodiment 3

[0022] refer to image 3 , is a schematic structural diagram of Embodiment 3 of the present invention. Compared with Embodiment 2, the difference of this embodiment is that the suspension frame 2 is a horizontal straight rod, and the balance mechanism is arranged between two parallelogram-shaped four-bar linkages , the pulley mechanism is directly fixed on the suspension frame 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com