Material rack component for laser cutter

A laser cutting machine and material rack technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of reducing the working efficiency of the laser cutting machine, difficulty in ensuring the flatness of the grid plate, and the non-movable and exchangeable material rack. , to achieve the effect of improving service life, stable and reasonable structure, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

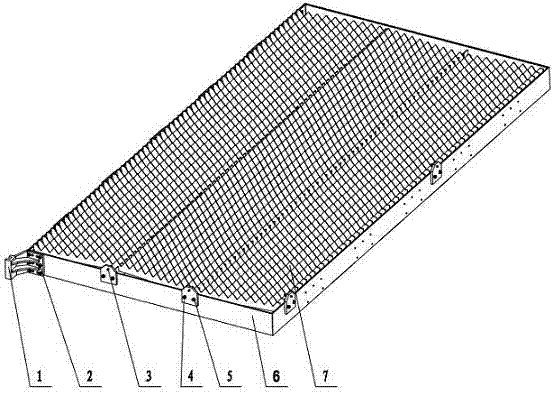

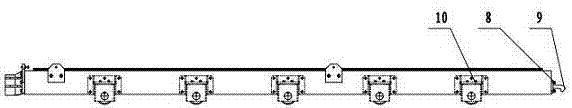

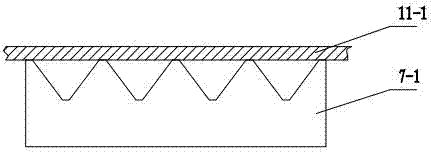

[0014] like Figure 1 to Figure 2 As shown, the laser cutting machine material rack assembly of the present invention includes a transmission hook 1, a screw 2, a hexagon head bolt 3, a positioning plate 4, a screw 5, a material rack frame 6, a support grid plate 7, a screw 8, and a fixing hook 9. Roller assembly 10.

[0015] The present invention adopts that a transmission hook 1 is installed on the front end of the rack frame 6 and fixed with screws 2, the fixed hook 9 is fixed on the rear end face of the rack frame 6 with screws 8, and the positioning plate 4 is respectively installed on the rack frame with screws 5 6 on the front and right sides, the hexagon head bolt 3 is installed in the threaded hole above the positioning plate 4, the support grid plate 7 is inserted into the slot hole on the top of the material rack frame 6, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com