Method for detecting overprint errors of photogravure press on the basis of field programmable gate array (FPGA)

A gravure printing machine and error detection technology, which is applied to printing machines, rotary printing machines, general parts of printing machinery, etc., can solve problems such as large fluctuations in color registration deviation detection, deviations in speed measurement, difficult high-speed and high-precision requirements, etc. Achieve the effects of improving real-time performance and accuracy, improving detection accuracy, and meeting registration requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

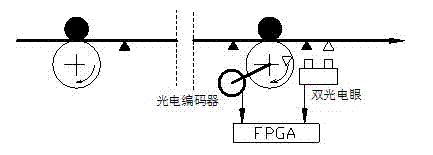

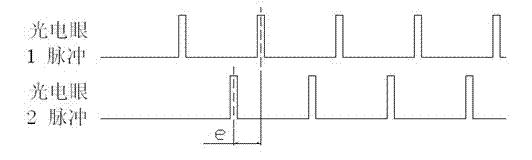

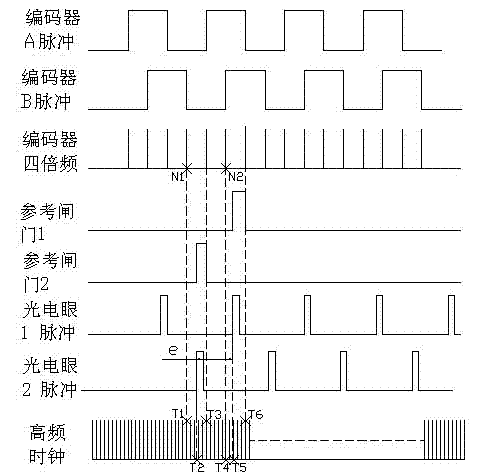

[0034] The dual photoeye consists of a light source, two condenser lenses and two photodetectors. The light source is converged by the lens, reflected by the reflector, and then converged to the surface of the photodetector by the lens, such as figure 1 shown. The distance between the two photoelectric eyes is 20mm, and the calibration of the system needs to be strictly adjusted. Take the overprint subsystem of the second color printing unit as an example, with the first color as the reference, when the second color overprint is accurate, the color marks of the first and second colors reach the two photoelectric eyes at the same time, and the two pulse signals output by the sensor There is no phase difference, so the overprint deviation e=0; and when the overprint is inaccurate, the color marks of the first and second colors cannot reach the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com