Test bed for making water

A technology of test bench and water bench, which is applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as circuit short circuit, sewer pipe leakage, operator sprain, etc., and achieve Ensure cleanliness, prevent short circuit and avoid silting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

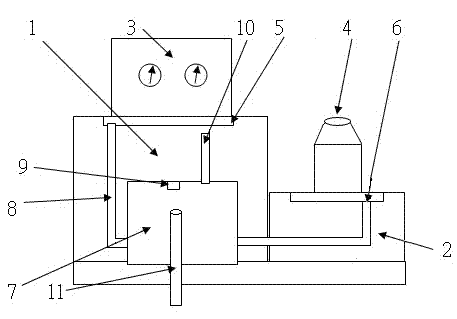

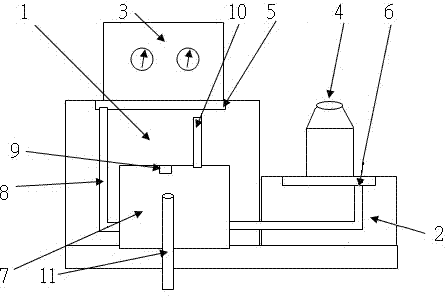

[0017] Below in conjunction with accompanying drawing, the present invention is further described in detail:

[0018] The invention relates to a test bench for water production, which includes two tables, specifically, a higher water production platform 1 and a lower water receiving platform 2, the water producing platform 1 and the water receiving platform 2 are hollow Design, the water making device 3 is arranged on the water making table 1, the barrel 4 is arranged on the water receiving table, there is a height difference of 30~50cm between the water making table 1 and the water receiving table 2, so that the purified The water is introduced into the barrel 4 relatively smoothly, and at the same time, a faucet (not shown in the figure) is set on the water-making platform 1 to supply raw water to be purified to the water-making device 3 .

[0019] In the present invention, the water-making platform 1 and the water-receiving platform 2 are provided with a water tank 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com