Marine clutch

A clutch and marine technology, applied in clutches, friction clutches, fluid-driven clutches, etc., can solve the problems of easy aging of rubber elastic elements, large radial and axial dimensions of clutches, and low axial and radial compensation capabilities. The overall structure is compact, the radial space is increased, and the axial size is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

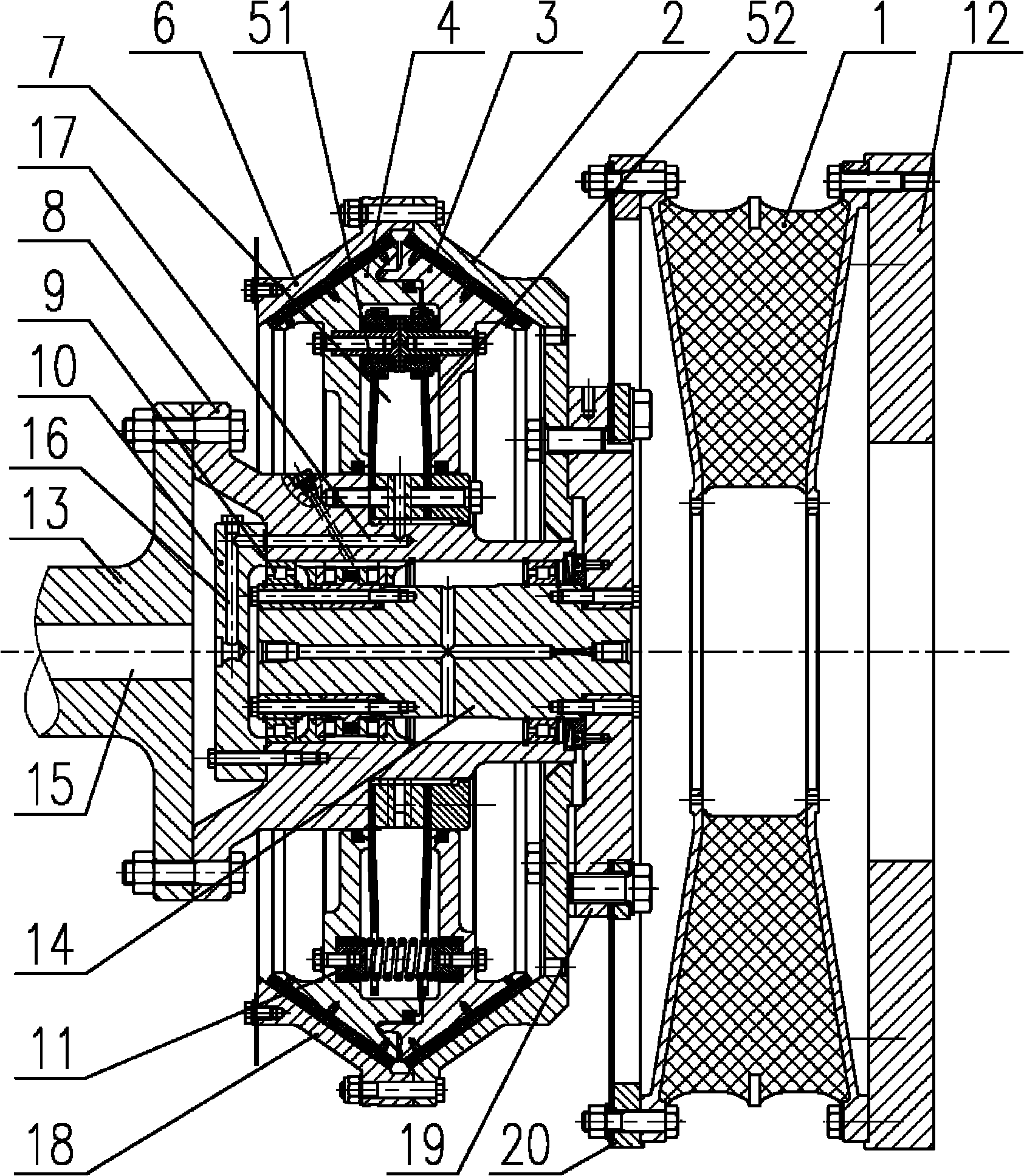

[0023] The present invention will be further described below in conjunction with accompanying drawing.

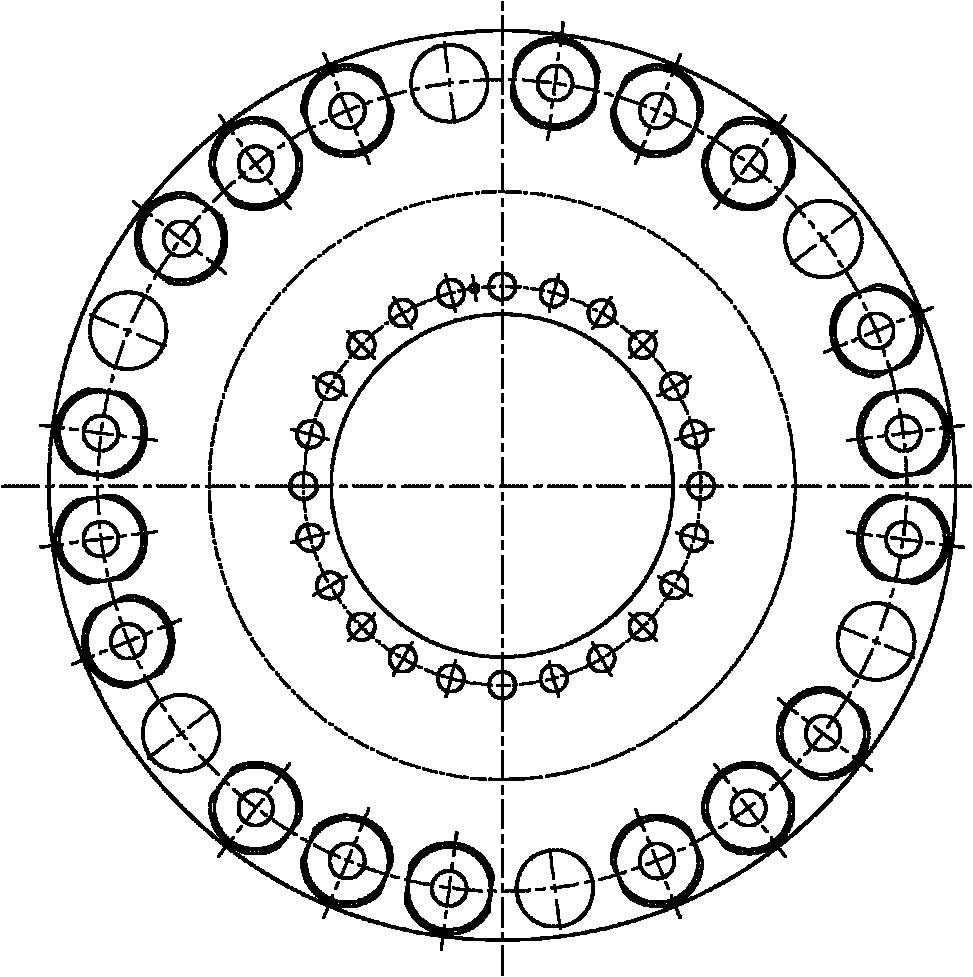

[0024] A marine clutch, including a clutch body 18, the clutch body 18 includes a first active friction cone 2, a first driven friction cone 3, a second active friction cone 6, a second driven friction cone 4, a hub 8, Gas distribution plate 10, cover plate 19, transition plate 20, gas distribution plate 10 is provided with air channel 16, one side of clutch body 18 is connected with gearbox input shaft 13, the other side of clutch body 18 is connected with diesel engine flywheel 12, clutch body 18 is connected to the side of the diesel engine flywheel 12 and is also provided with a high elastic element 1 between the clutch body 18 and the diesel engine flywheel 12, between the first driven friction cone 3, the second driven friction cone 4, the hub 8 and the mandrel 14 The first diaphragm assembly 51 and the second diaphragm assembly 52 are arranged between them, and there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com