Automatic detecting system for detecting coke thickness by hydraulic decoking

An automatic detection and coke cutting coke technology, which is applied in the direction of measuring devices, instruments, petroleum industry, etc., can solve the problems of affecting coke cutting, affecting the coke cutting process, and poor line of sight, so as to improve the level of automation, ensure measurement accuracy, reduce effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

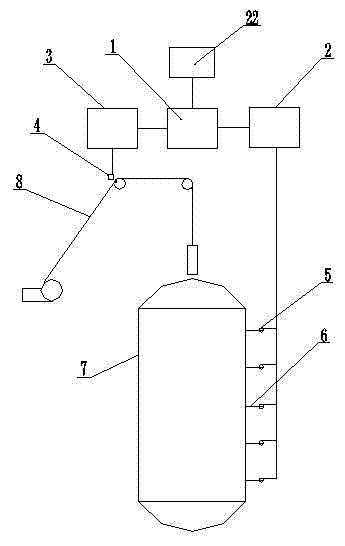

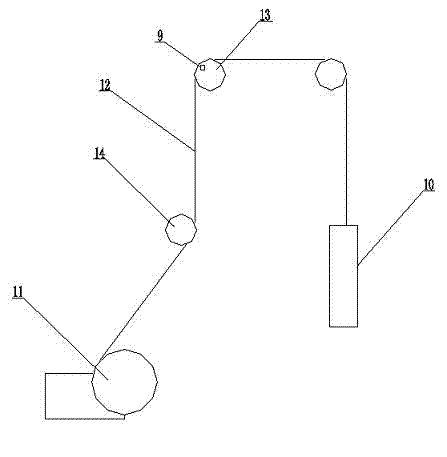

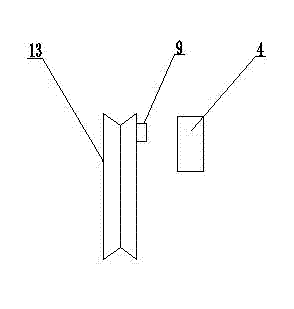

[0017] As shown in the figure, the hydraulic coke cutting coke thickness automatic detection system is composed of a computer 1, a dynamic signal analyzer 2, a PLC controller 3, a proximity sensor 4 and 4-6 vibration sensors 5, and the vibration sensors 5 pass through the installation bracket 6 along the The vertical direction is arranged at intervals on the outer wall of the coke tower 7, the vibration sensor 5 is connected with the dynamic signal analyzer 2 through the signal line, and the proximity sensor 4 is arranged on one side of the lifting mechanism 8 of the coke cutting device 10, and the lifting mechanism 8 is provided with Induction block 9, proximity sensor 4 are connected with PLC controller 3 through signal line, dynamic signal analyzer 2 and PLC controller 3 are connected with computer 1 respectively, and computer 1 is provided with display 22, can display analysis result.

[0018] The distance between two adjacent vibration sensors 5 is 3-8 meters, and generall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com