Calorimeter signal acquisition device, calorimeters and method for computing heating load

A technology of heat collection and signal collection, which is applied in the field of heat meters, can solve the problems of high price, impact on accuracy, and degree of pipe wall corrosion, and achieve the effects of low cost, large measurement range, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

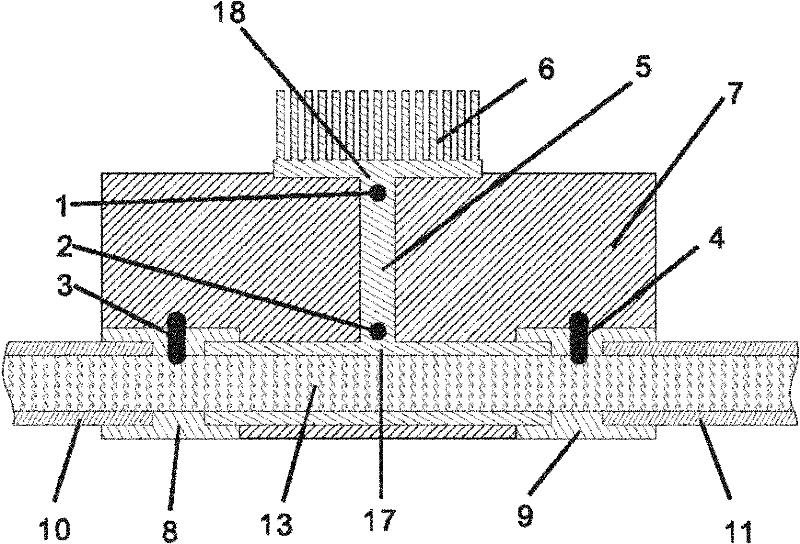

Embodiment 1

[0021] This example figure 1 As shown, adopt heat-conducting material to make a heat-conducting body 5, and one side is in contact with the heat-carrying fluid in the pipeline, is referred to as the heat collection surface 17 here, and the other side is made radiator 6 (also can be connected on a radiator), here It is called the heat dissipation surface 18, and a relatively long and narrow area is made in the heat conduction path from the pipe to the radiator, and then the heat dissipation end temperature sensor 1 and the heat collection end temperature sensor 2 are respectively arranged at both ends of the long and narrow area, and the outer surface of the heat conductor The surface, except the heat collection surface 17 and the heat dissipation surface 18, has adopted thermal insulation measures, for example, covered with thermal insulation material or thermal insulation material, and a vacuum insulation layer can also be set.

[0022] In this embodiment, the heat conductor ...

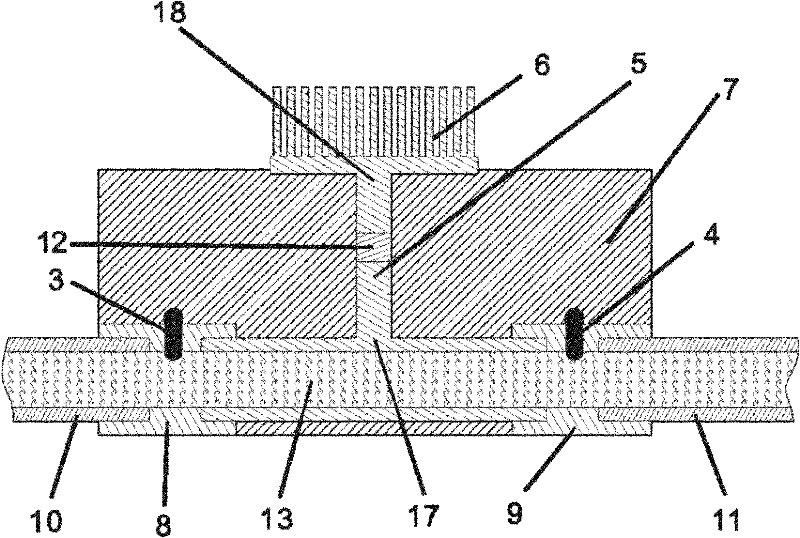

Embodiment 2

[0027] This example figure 2 As shown, two heat conductors are made of heat-conducting materials. One end surface of the first heat conductor 5 is in contact with the heat-carrying fluid in the pipeline, which is called the heat collection surface 17 here, and the other opposite end surface is in contact with the hot end of the refrigeration semiconductor 12. One end face of the second heat conductor is connected to the cold end of the refrigeration semiconductor 12, and the other opposite end face is made into a radiator 6 (it can also be connected to a radiator), which is composed of two heat conductors and a refrigeration semiconductor. unit. A heat conduction unit is formed by two heat conductors and refrigeration semiconductors. The outer surface of the heat conduction unit, except for the two heat collection surfaces 17 and the heat dissipation surface 18, has adopted heat preservation measures, for example, covered with heat preservation material or heat insulation mat...

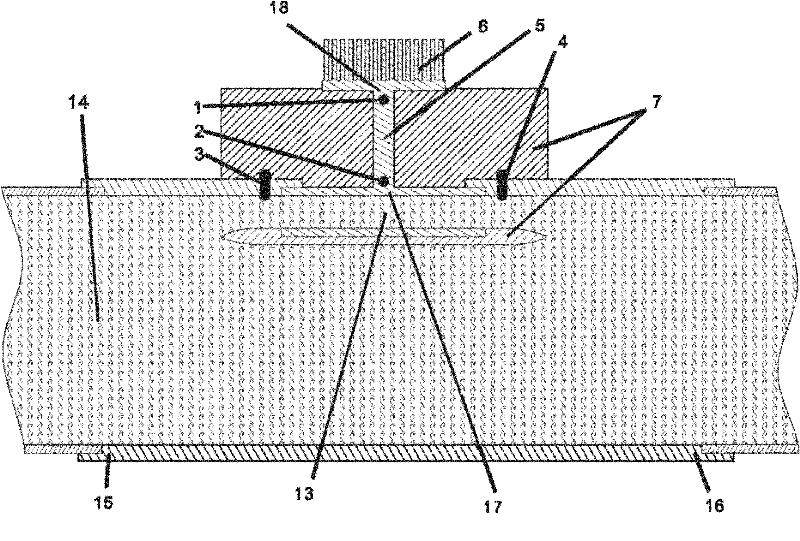

Embodiment 3

[0031] Embodiment 3 is applicable to the measurement of heat supply in the case of a larger pipe diameter or a larger flow rate of a heat-carrying fluid. This is like image 3 As shown, the difference between embodiment 3 and embodiment 1 is that when the diameter of the pipe is larger or the flow rate of the heat-carrying fluid is larger, the temperature measured between the upstream temperature sensor 3 and the downstream temperature sensor 4 using the structure of embodiment 1 The temperature difference will be very small, which is not conducive to collection and calculation. For better measurement, the large-diameter pipeline heat meter adopts a composite pipeline structure. In the main pipeline, a multiple tube 13 wrapped with an insulating material is set up, and the heat carrying heat flowing through the multiple tube Due to the thin pipe diameter and low flow rate of the fluid, the temperature changes at the upstream 3 and downstream 4 are relatively large. A temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com