Sampling and liquid level detection device for automatic sampling system

A liquid level detection and automatic technology, which is applied to sampling devices and displays liquid level indicators through pressure measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The present invention will be further described below in conjunction with accompanying drawing:

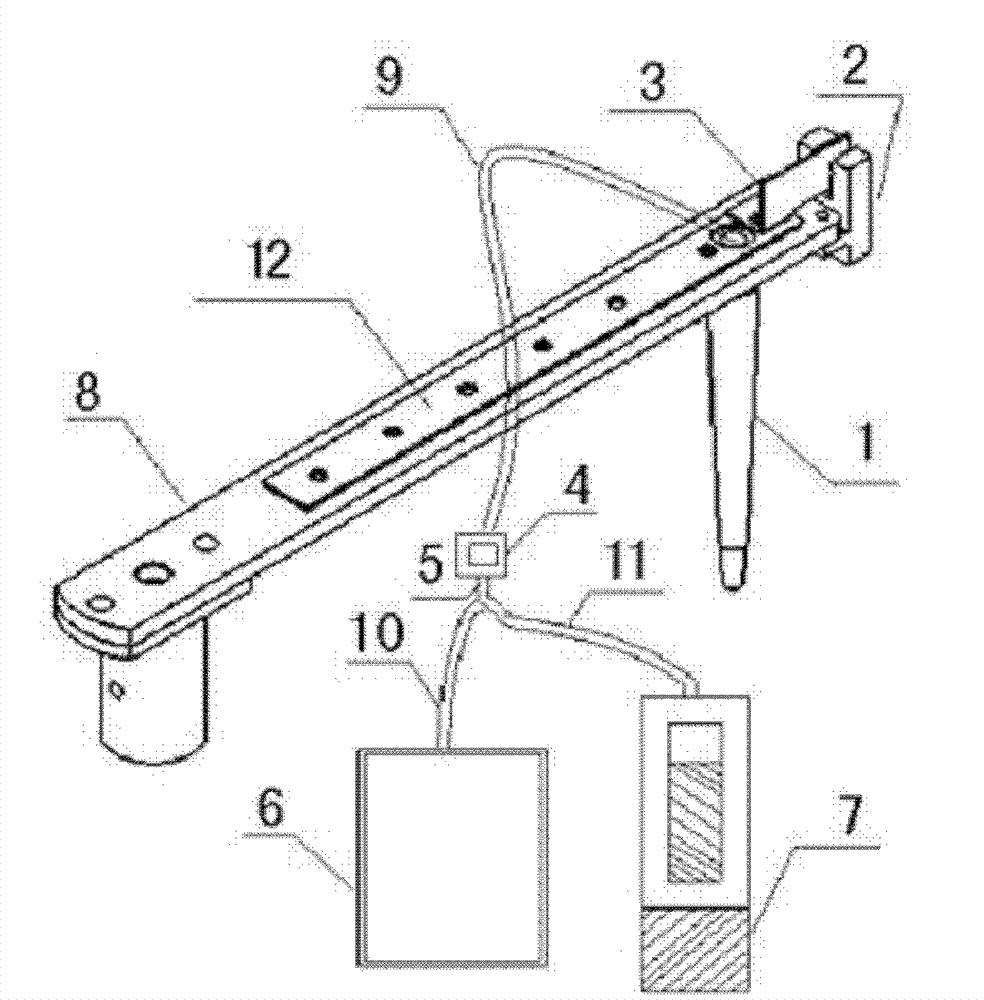

[0011] Such as figure 1 As shown, 1 sampling head connection mechanism; 2 sampling head in-position detection sensor; 3 sampling head in-position stopper; 4 differential pressure sensor; 5 three-way communication valve; 6 negative pressure generating mechanism; 7 plunger pump; 8 sampling arm beam; 9 the liquid pipe; 10 the liquid pipe connected with the negative pressure generating device; 11 the liquid pipe connected with the plunger pump; 12 the elastic plate.

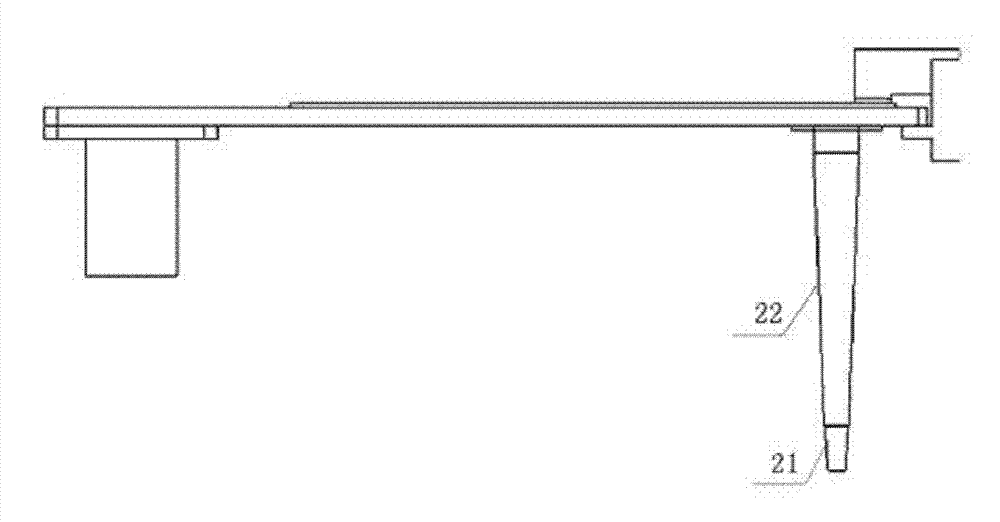

[0012] Such as figure 2 As shown, 21 small TIP head loading positions; 22 large TIP head loading positions.

[0013] When the sampling arm mechanism moves to the TIP head area (not shown in the figure), the sampling arm crossbeam 8 descends, driving the sampling head connection mechanism 1 to move downward, and when it touches the TIP head, the deformation of the pressure elastic device 12 drives the sampling h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com