Automatic assembly type photodynamic drill based on multi-core fiber

A multi-core optical fiber, optodynamic technology, applied in cladding optical fiber, optical waveguide light guide, radiation/particle processing, etc., can solve the problems such as the unstable rotation of the rotor and the limited application range of the optical drive device, saving physical space, Simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in more detail below in conjunction with the accompanying drawings by taking a three-core optical fiber as an example:

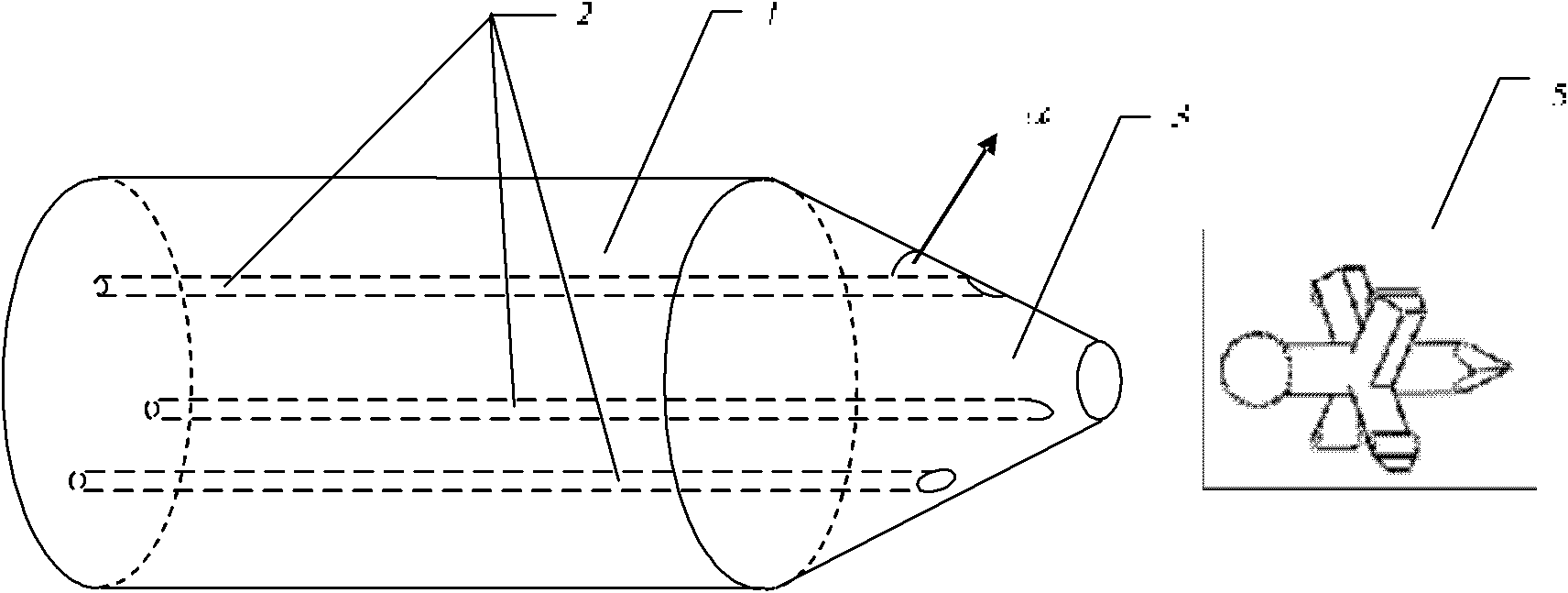

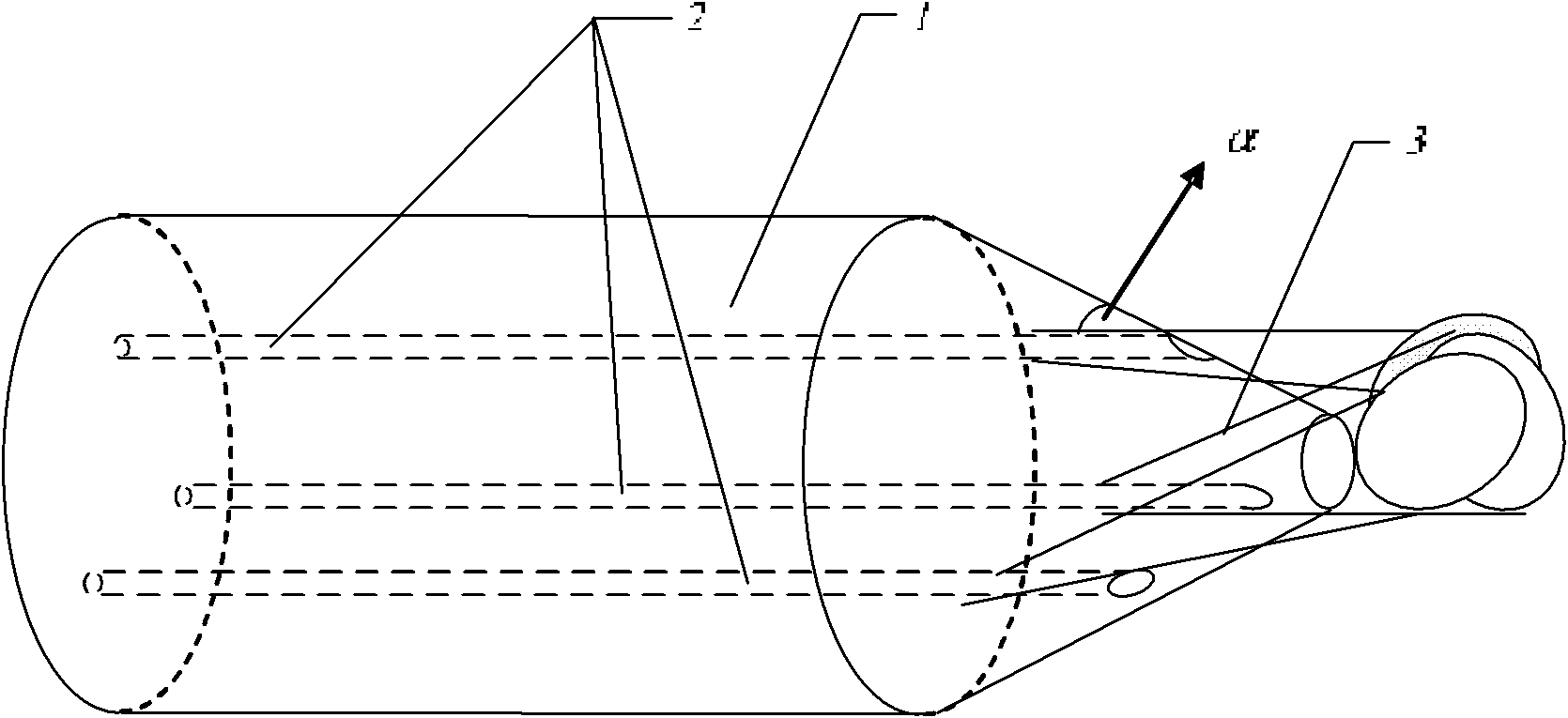

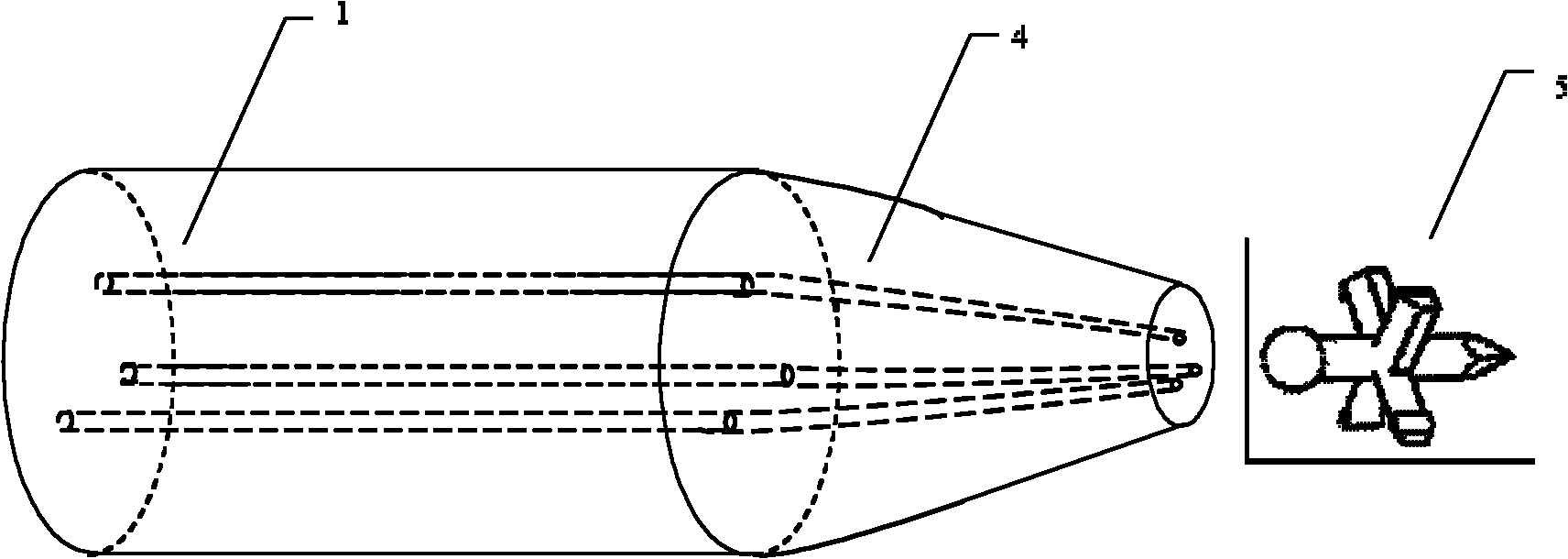

[0032] combine figure 1 , 3, it is mainly composed of the optical tweezers 4 formed by the finely processed multi-core optical fiber 1 at the front end, which automatically captures the sphere of the micro-rotor 5 in the solution to form an optical power drill system; Figure 7-9 , the micro-rotor structure includes a top sphere, a rotating shaft, a "windmill-like" rotor structure that connects multiple wings with slopes and semi-cylinders, and the bottom end is a cone tip; after the front end of the multi-core optical fiber captures the sphere, it plays a role While the axis is fixed, the outgoing light is irradiated vertically to the wing with the slope to realize the rotation, and at the same time, it drives the bottom cone to rotate to play the role of a photodynamic drill. The multi-core optical fiber whos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com