Method for manufacturing CMOS (complementary metal-oxide-semiconductor transistor) image sensor

A technology of image sensor and manufacturing method, which is applied in the direction of radiation control devices, etc., can solve problems such as image delay of CMOS image sensors, and achieve the effects of reducing image delay, improving collection efficiency, and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

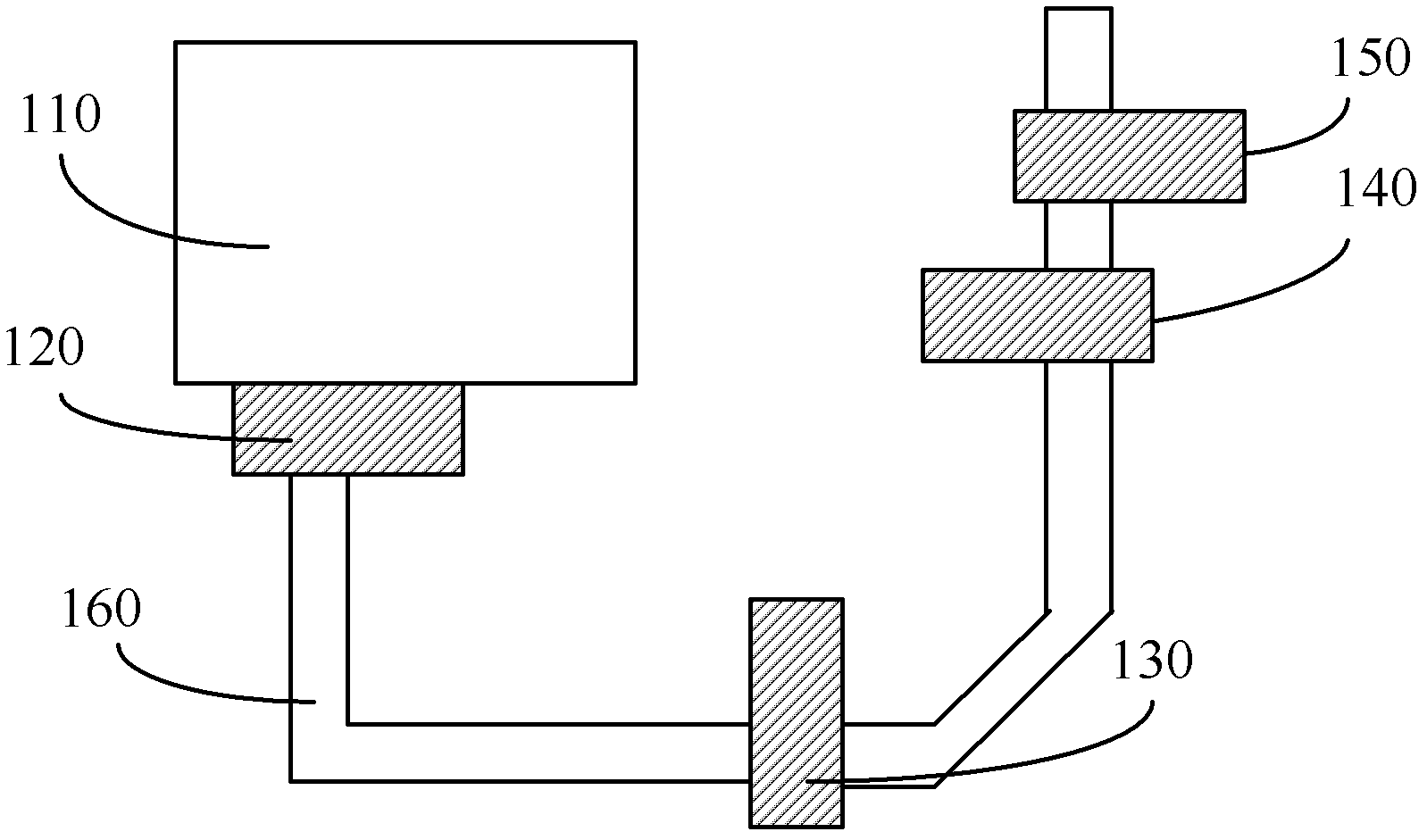

[0024] The CMOS image sensor manufacturing method provided by the present invention, by forming a novel photodiode structure, improves the photodiode’s ability to transfer photoelectrons, increases the diffusion speed of photoelectrons, and reduces the number of photoelectrons stranded in the photodiode, thereby achieving more For effective photoelectron transfer, the image quality, performance and resolution of CMOS image sensors are further improved.

[0025] The manufacturing method of the CMOS image sensor of the present invention will be described in detail below with reference to specific embodiments and accompanying drawings.

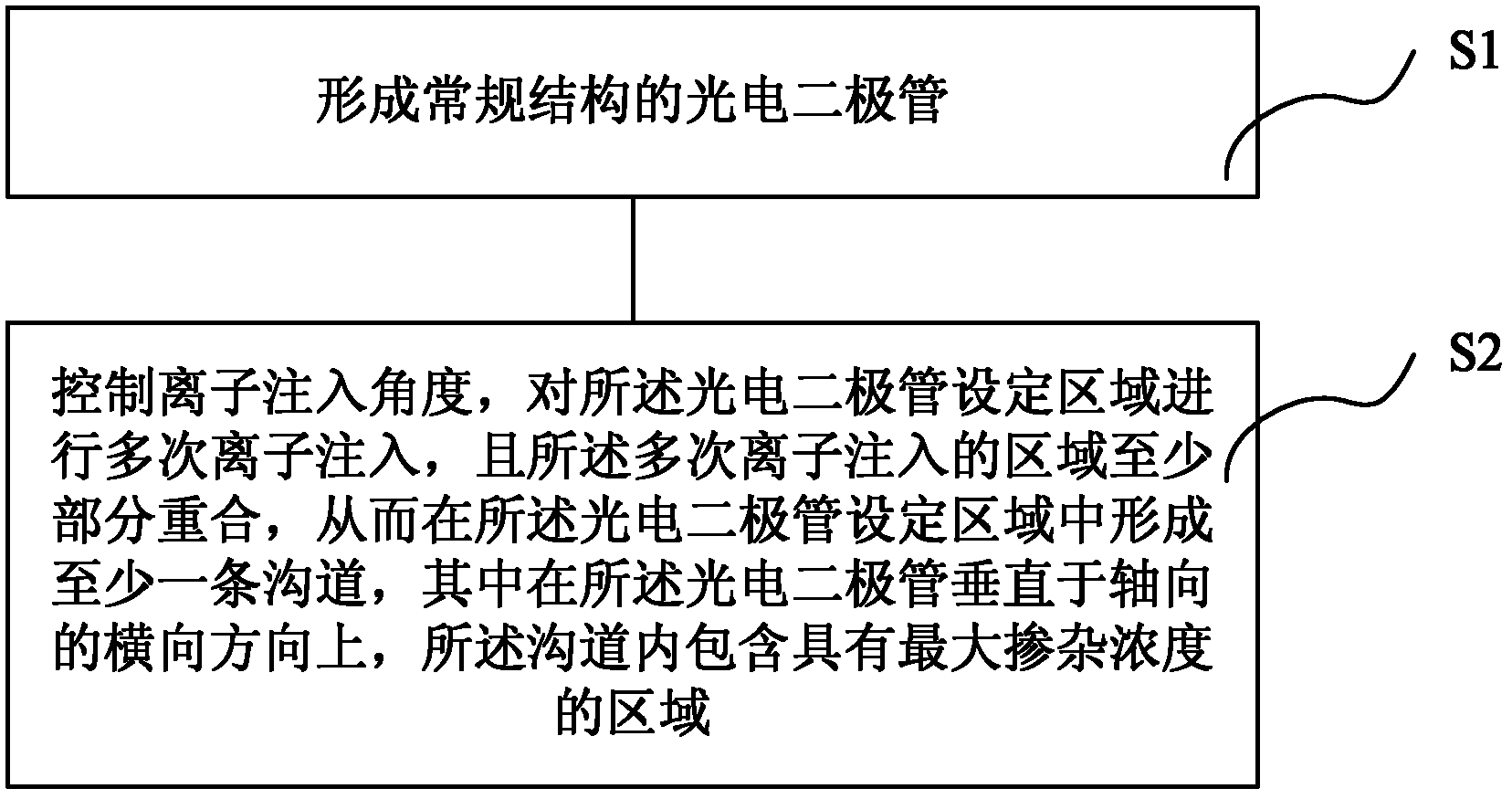

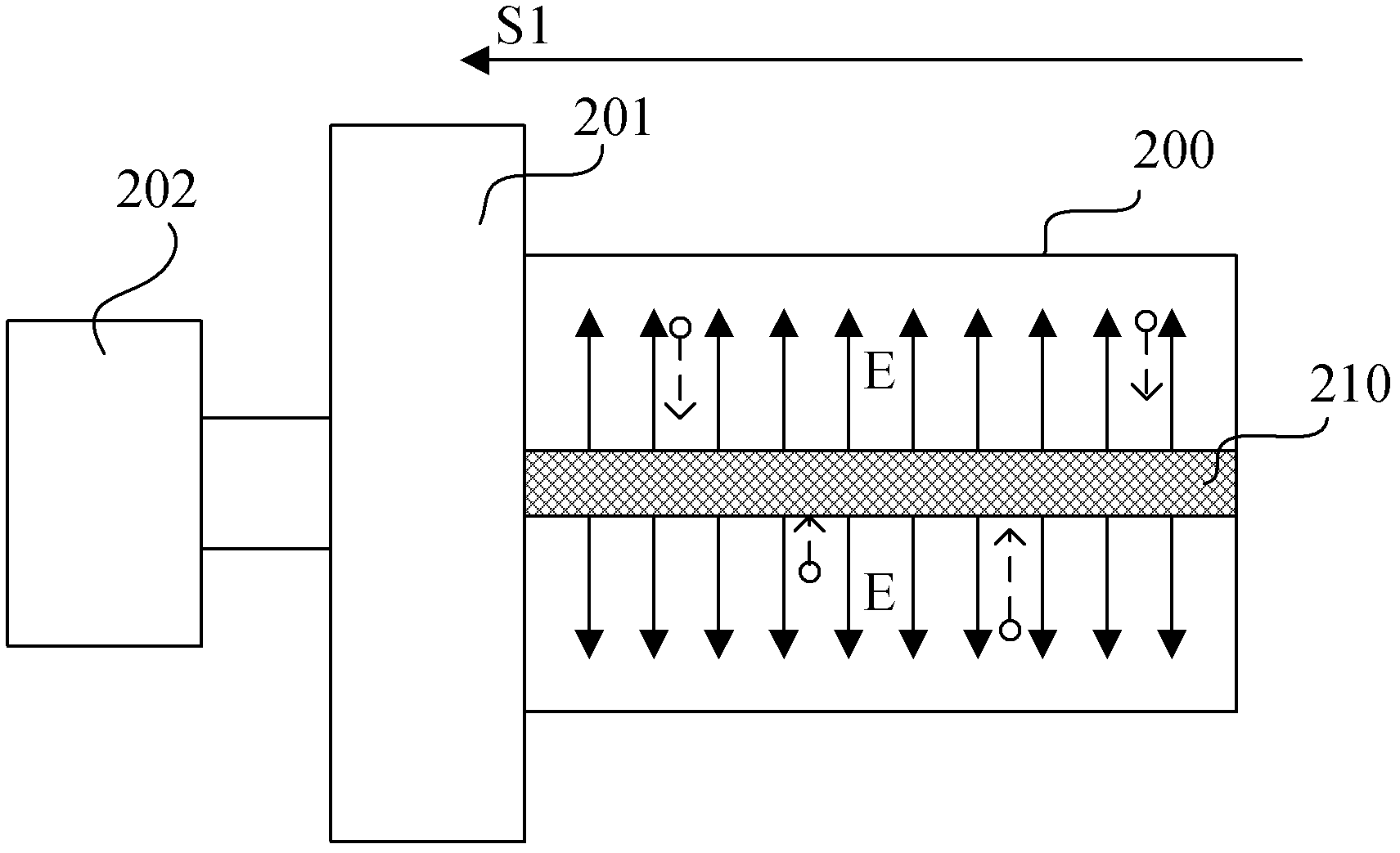

[0026] refer to figure 2 , in one embodiment, the CMOS image sensor manufacturing method of the present invention comprises:

[0027] Step S1, forming a photodiode with a conventional structure;

[0028] Step S2, controlling the ion implantation angle, performing multiple ion implantations on the set area of the photodiode, and the areas of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com