Backpack motor-driven sprayer with rope-pull falling-back starting function

A knapsack, sprayer technology, used in starting devices with manual cranks, starting devices with mechanical power storage, engine components, etc., can solve the problem of increased spacing, stuck starting disc, poor rigidity of nylon materials, etc. problem, to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with the above-mentioned drawings.

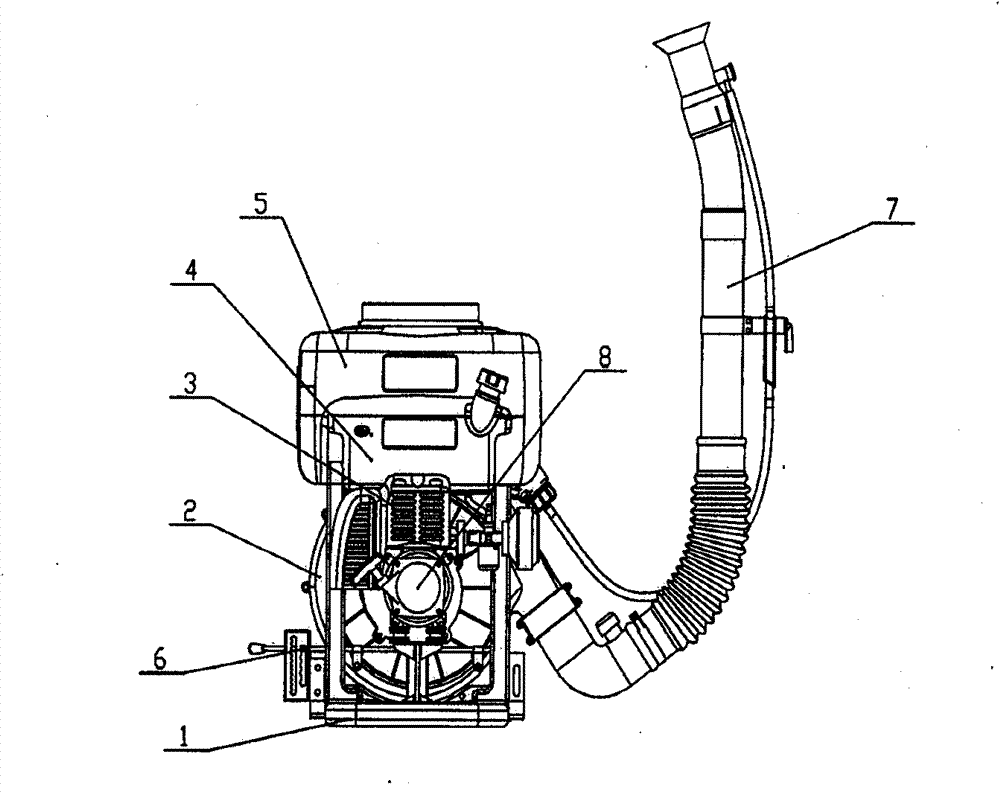

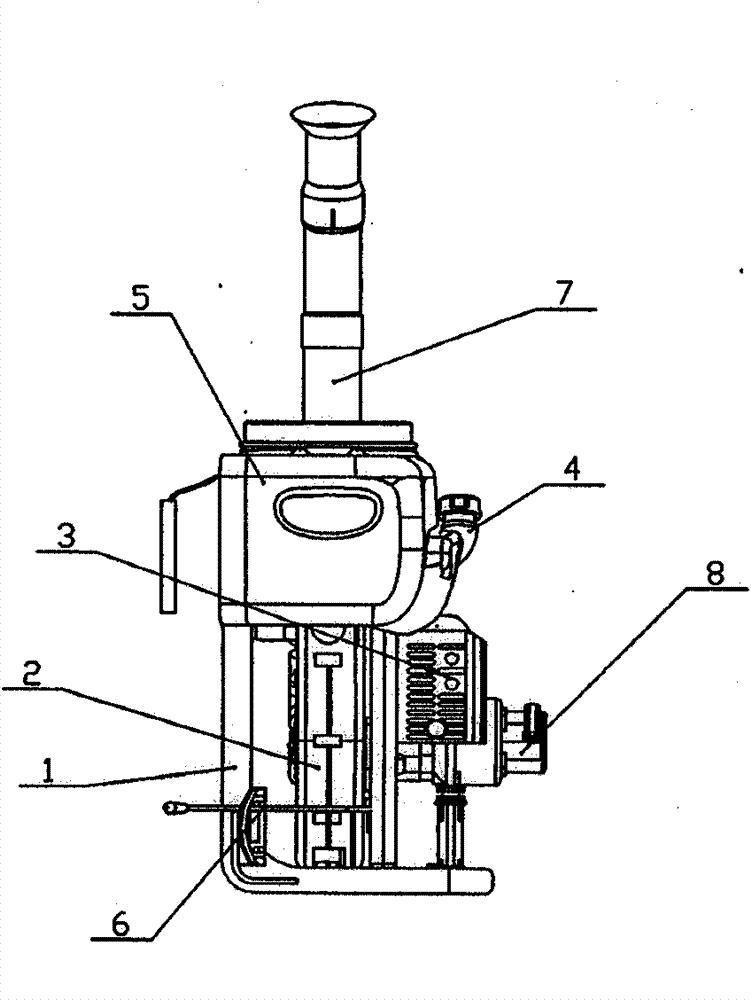

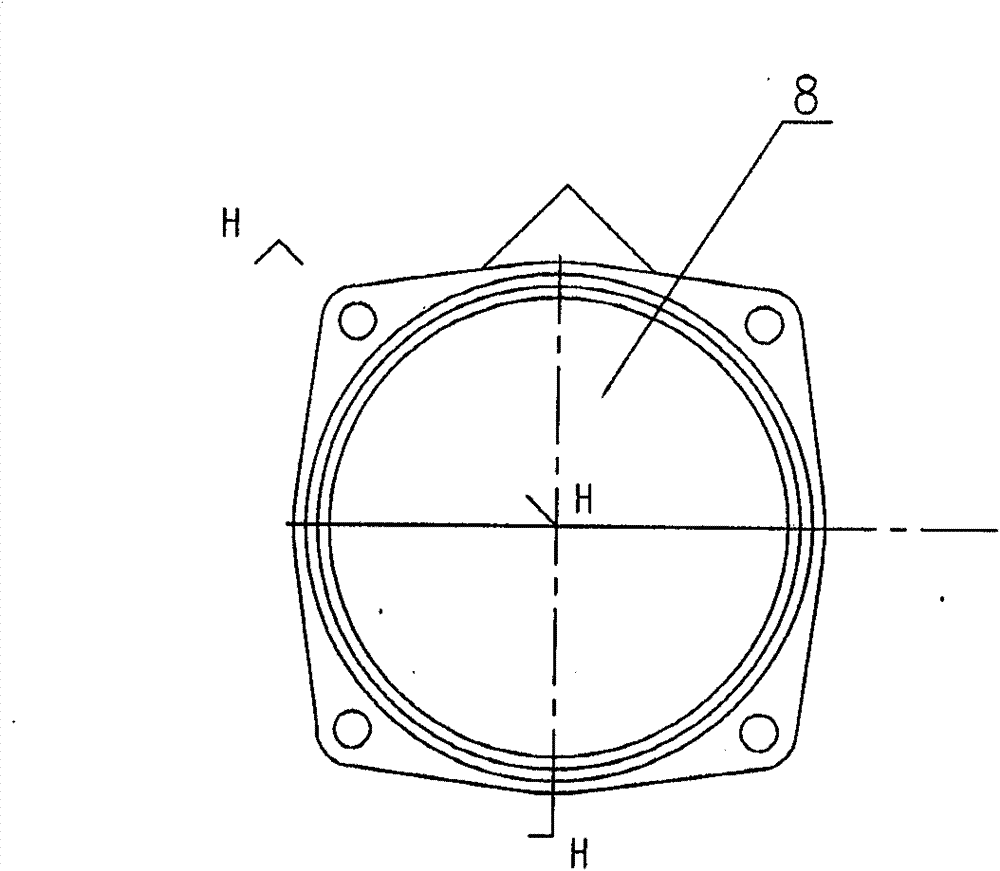

[0037] Such as Figure 1~2Shown, a kind of knapsack type motorized sprayer with the function of rope pulling back and starting, it comprises frame 1, blower fan 2, gasoline engine 3, fuel tank 4, medicine box 5, control part 6, spraying part 7, it is characterized in that, above-mentioned The gasoline engine is also equipped with a starter 8, such as Figure 3-20 As shown, the starter 8 comprises a starting shaft 81, a pawl clutch 82, a spring seat 83, a starting disc 84, a back-moving spring 85, a pull cord 86, a casing 87, a starting handle 88, and one end of the starting shaft 81 is a one-way ratchet 811, the other end is a circular shaft 812; the pawl clutch 82 is mounted on the rotor S of the gasoline engine, and can be engaged or separated from the one-way ratchet 811. Usually, the one-way ratchet 811 and the pawl clutch 82 are engaged; the Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com