Method for drying strontium chloride hexahydrate

A technology of strontium chloride hexahydrate and drying method is applied in the directions of drying solid materials, heating to dry solid materials, drying, etc., which can solve the problems of low utilization rate of heat energy and large energy loss, and achieve high utilization rate of heat energy and prevent The effect of pulverization and air volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

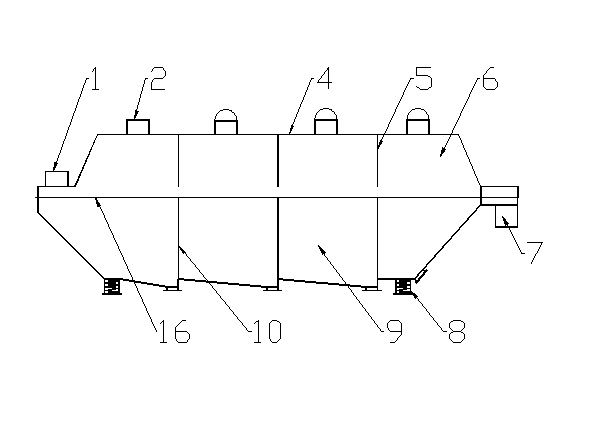

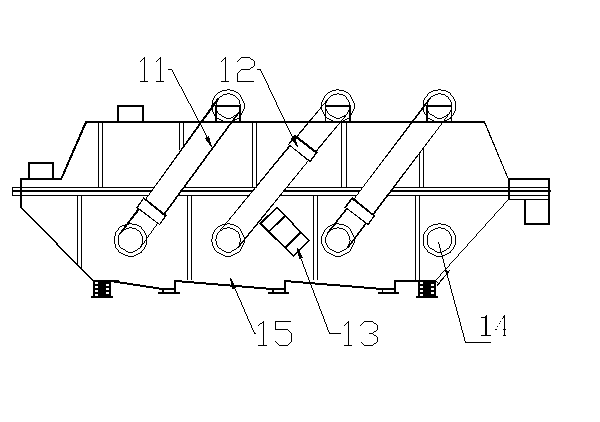

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

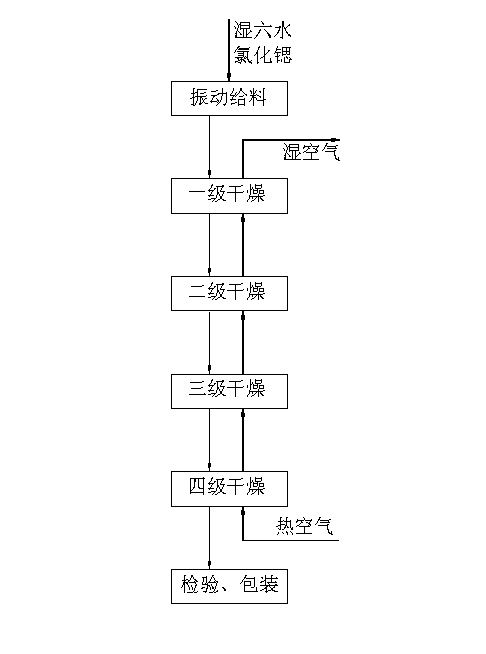

[0017] See attached figure 1 , the flow chart in the figure is the steps of the drying method of strontium chloride hexahydrate disclosed by the present invention, which is characterized in that it comprises the following methods and steps:

[0018] 1). Feeding: Add the centrifuged strontium chloride hexahydrate to the feeding port of the multi-stage fluidized bed through a vibrating feeder, so that it is evenly distributed on the gas distribution plate of the fluidized bed;

[0019] 2). Multi-stage drying: The fluidized bed is divided into several fluidized chambers connected to each other. The material can flow along the gas distribution plate, and the strontium chloride hexahydrate passes through the fluidization process in sequence along the gas distribution plate under the vibration of the fluidized bed. At the same time, hot air with a temperature of 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com