Dynamic weighing method of vehicle and apparatus thereof

A dynamic weighing and vehicle technology, applied to measuring devices, detailed information of weighing equipment, weighing, etc., to achieve the effect of preventing vehicle loss and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

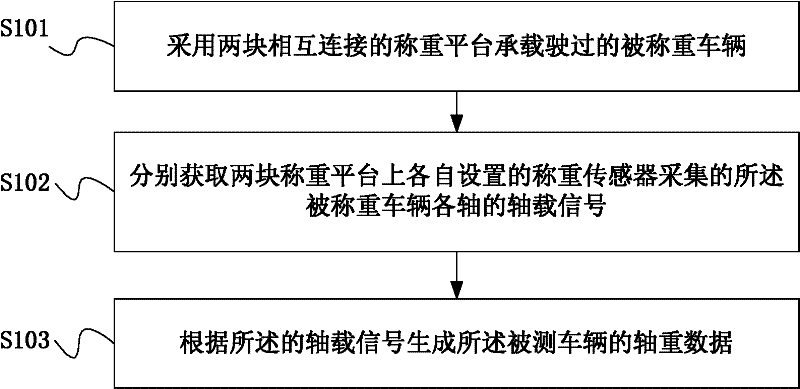

Method used

Image

Examples

Embodiment 1

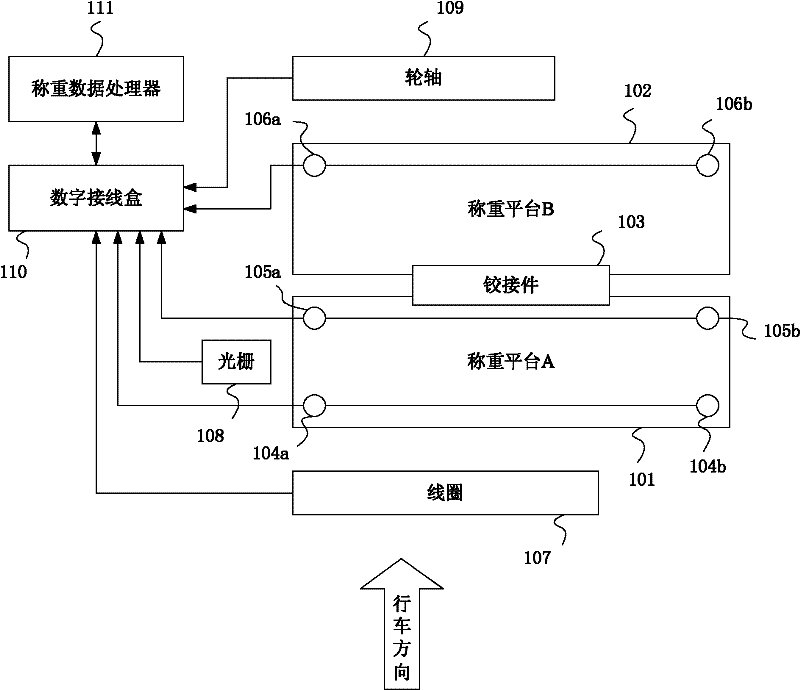

[0025] Such as figure 1 Shown is the arrangement scheme of the conjoined platform weighing device of this embodiment. Wherein, the weighing platform 101 and the weighing platform 102 are hinged by using the hinge 103 to form an articulated weighing platform for carrying the vehicle to be weighed. The center distance between the weighing platform 101 and the weighing platform 102 is about 800mm.

[0026] Load cells (104a and 104b, 105a and 105b) are arranged on the fulcrums of the four corners of the weighing platform 101 . Load cells (106a and 106b) are arranged on the fulcrums of the two corners on one side of the weighing platform 102 . Wherein, sensor 104a is connected with sensor 104b to form a first group of sensors, sensor 105a is connected to sensor 105b to form a second group of sensors, and sensor 106a is connected to sensor 106b to form a third group of sensors.

[0027] The weighing platform 101 is fixed and supported by the fulcrums located at its four corners. ...

Embodiment 2

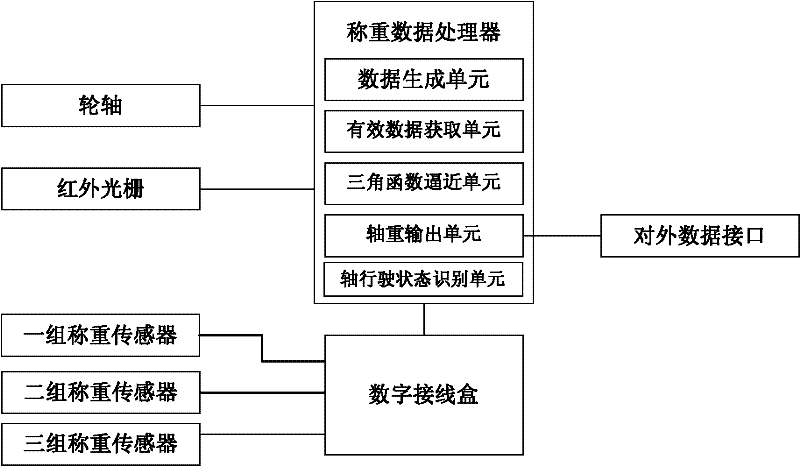

[0035] Such as image 3 As shown, the vehicle dynamic weighing device of this embodiment includes: two weighing platforms connected to each other, used to carry the vehicles to be weighed passing by; three groups of load cells are respectively arranged on the two weighing platforms, It is used to collect the axle load signal of each axle of the vehicle being weighed; the weighing data processor is used to receive the axle load signal and generate the axle load data of the vehicle under test according to the axle load signal; the external data interface or display screen is used for Output the said axle load data.

[0036] The two weighing platforms are rectangular, and the two weighing platforms are hinged.

[0037] Set two sets of load cells on one of the two weighing platforms, and set a set of load cells on the other of the two weighing platforms; the weighing data processor obtains two sets of load cells respectively. The axle load signals of each axle of the vehicle bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com